- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating rods

Results for

Heating rods - Import export

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric Air heater Electrical air heater type “LEH-A” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The air heater essentially consist of the following main-components: Process flange Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

EEx’e’ certified electric duct air heater EEx e T2 – T6 ATEX The “LEH-Exe” type electric heaters comprise a range of certified EEx e air duct heaters, custom built to meet client specifications and suitable for use in zone 1 & 2 hazardous areas. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The duct heaters essentially consist of the following main-components: Duct with flat flanges Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric duct heater Electrical duct heater type “LEH-R” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The duct heaters essentially consist of the following main-components: Duct with adapters to flanges DIN EN 1092 Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric duct heater Electrical duct heater type “LEH-K” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The duct heaters essentially consist of the following main-components: Duct with flat flanges Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

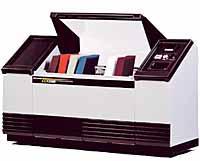

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

Do you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Temperature range: 250 °C to 3200 °C 4-year warranty Durable IP65 (NEMA4) housing Manual Variable focus Sighting options: Laser through the lens and Visible through the lens Video Camera through the lens and Visible through the lens LED through the lens and Visible through the lens LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring and field calibration Single or two color models available APPLICATIONS Metals processing: molten metal/forging, hot rolling mills, rod/wire mills Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Broad temperature range 50 to 3200°C 4-year warranty Durable IP65 (NEMA4) housing Visible through the lens sighting and manual variable focus plus optional laser sighting, video camera, or LED sighting LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring, and field calibration In addition to single-color models, the series also comprises two-color (ratio) pyrometers and models with a remote sensor head (Endurance Glass-Fiber). APPLICATIONS Metals: forging, hot rolling, rod/wire production Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The electrical steam generators E 100 M – 120 M from CERTUSS offer you impressive output in two output capacities of 100 - 120 kW heat output. They are compact, economical and have a high output. All electrical versions do not require a permit for installation and use in Germany. Heating: Electrical heating rods Steam output 135 – 160 kg/h The sizes: E 100 and E 120 - In two output capacities of 100 - 120 kW heat output. - Fully electronic pressure and output control. - Compact stainless steel heating rod with low heating surface load, placed laterally on the pressure body for easy access. - Constant network load without consumption peaks. - Integrated multifunction display. - Multilanguage plain text indication.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

With the new EMX model range of electric steam boilers, CERTUSS offers you twice the steam output as before with a significantly smaller footprint. Electric steam generators from CERTUSS are heated by stainless steel heating rods with a large heating surface. The output of the heating elements is regulated continuously via semiconductor contactors. One energy-efficient advantage is the immediate modulating output adjustment to the actual steam demand during the operating cycle. For greater steam demand of up to 640 kg/h or fluctuating steam loads, several ELECTRO steam generators can be cascaded in series. Multiple systems like this are an especially economical solution. Our compact electric steam systems feature built-in feed water tanks and feed water pumps. They require very little space and have a short heat-up time. Steam systems are also available as a unit with water conditioning equipment installed at the factory.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The electrical steam generators E 6 M - E 72 M from CERTUSS offer you impressive output in 14 different output sizes. They are compact, economical and have a high output. All electrical versions do not require a permit for installation and use in Germany. Heating: Electrical heating rods Steam output 8 - 97 kg/h The compact: E 6 M – E 72 M - In 14 different output sizes. - Easy-to-service compact device – easy to operate. - Direct access to all parts from the front for easy maintenance. - Fully electronic pressure and output control, immediate load adjustment. - Function and malfunction indications can be linked to central control system / building services control system provided by - customer. - Low space requirement, reduced and robust heavy-duty model in elegant design. - Fully automatic operation by means of time control or remote pulse (optional). - Automatic clarification and desalination (optional).

Request for a quote

ASSFALG GMBH

Germany

The circular dryers are used for stainless drying of all types of workpieces. By using the hot-air blower or the indirect heating through heating rods below the tub, a uniform drying of the workpieces and the drying granulate is ensured. The additional advantage is that it brightens, repolishes and degreases workpieces. Both versions can be configured as individual systems in combination with a new vibratory finishing machine or as a module for an existing vibratory finishing machine. The drying medium and the workpieces are brought into a rotational movement through a generated vibration. The desired drying or post-treatment process are created through the contact of the drying medium and workpieces. The workpieces are automatically screened out of the dryer and transported from the device through the optional manual or pneumatic separation equipment.

Request for a quoteResults for

Heating rods - Import exportNumber of results

12 ProductsCountries

Company type