- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating boilers

Results for

Heating boilers - Import export

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Simple operation and fully automated operation of up to four hot water or heating boilers (master/slave). Compact "plug and play" control with innovative connectivity. — Modular complete solution with cost advantage, for all single-flame-tube hot water and heating boilers — Intelligent sequence control for up to four boilers — Intuitive operation via colour touch display and function keys for quick access — Pre-configured and completely wired for quick commissioning — Integrated power supply in the compact control cabinet, e.g. for burner and pumps — Compatible with all common automation system protocols — Optional remote access via MEC Remote for maximum availability

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The heating boiler UT-L offers high performance and is extremely compact. The design complies with the Gas Appliances Regulation. — Very high efficiency up to 105% for optimised energy costs — Compact design for easy positioning and effective use of heat — Flexible application and low return flow temperature of 50 °C possible — Specific control concept and optional real-time monitoring — Future-proof heat supply and options for CO2-neutral operation — Proven and durable Bosch system from a single source — Fuel: Oil, gas, multi-fuel firing, Biogas, bio-oil, hydrogen, special fuels

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Conventional fired heat generator with additionally integrated smoke tube pass for waste heat utilization — Environmentally friendly generation of thermal heat or process heat through the utilisation of waste heat sources — High supply reliability thanks to self-firing function — Robust, reliable and durable — Versatile design for use with different fuel types and as a multi-fuel firing unit (oil, gas, biogas, hydrogen) — Ideal for combination with combined heat and power units or gas turbines

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Ideal for combination with combined heat and power units or gas turbines — Environmentally friendly generation of steam and hot water from available waste heat — High efficiency through efficient tubular heat exchanger and thermal insulation — Cost-efficient to purchase and operate as no burner is necessary

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Environmentally friendly generation of steam from available waste heat — The perfect addition to energy concepts involving combined heat and power generation — High efficiency through efficient tubular heat exchanger and thermal insulation — Additional efficiency gain thanks to optional integrated economiser — Matched, modular system for easy planning and fast installation

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quote

APROVIS

Germany

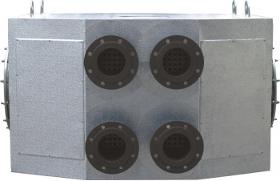

What you can expect from APROVIS exhaust gas heat exchangers: - Efficient hot water generation in combined heat and power plants - Heating of thermal oil as an energy source - Individual solutions and compact designs - All the main components for the exhaust gas section and gas treatment are combined under one roof: proprietary products developed in-house - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives

Request for a quote

BORSIG GMBH

Germany

BORSIG supplies synthesis gas boilers for gas pressures up to 350 bar (35,000 kPa) and steam pressures up to 160 bar (16,000 kPa). They are used in the synthesis gas loop of ammonia plants. The boilers are equipped with U-tubes and can be mounted both in the vertical as well as in the horizontal positions. With both designs, the steam drum can be integrated into the boiler if requested by the customer. At the same time, a feed water pre-heater can be installed in the boiler when required.

Request for a quote

BORSIG GMBH

Germany

BORSIG manufactures reformed gas waste heat boilers for more than 50 years. We supply reformed gas waste heat boilers for gas inlet temperatures of up to 1,200°C and steam pressures of up to 160 bar (16,000 kPa) for petrochemical industry (ammonia plants, methanol plants, hydrogen plants, ethylene plants, styrene plants, MTBE plants, oxo-alcohol plants, direct reduction iron plants, coas gasification plants, gas to liquid plants, and others. Every reformed gas waste heat boiler is designed and manufactured exactly in accordance with the customer´s individual requirements. BORSIG offers two different designs: 1. Reformed gas waste heat boilers with BORSIG´s thin stiffened tube sheet design 2. Reformed gas waste heat boilers with thin flexible tube sheet design.

Request for a quote

BORSIG GMBH

Germany

BORSIG has developed its own boiler design. This boiler design is suitable for all gasification processes. The waste heat boiler is designed as a fire-tube boiler. The hot synthesis gas enters the heating surfaces with a temperature of about 1,400 °C and is cooled down in these tubes to approximately 300 °C. The heat from the synthesis gas is used for generating saturated steam.

Request for a quote

BORSIG GMBH

Germany

BORSIG patented steam superheaters are suitable for steam pressures of up to 160 bar (16,000 kPa). The steam superheaters are arranged direct in line after the waste heat boilers which are connected to the secondary reformer or reformer – depending on the process. The steam superheater can be provided as two stage or one stage, horizontally or vertically arranged. The final design arrangement is determined by the process requirements. We have delivered steam superheaters for superheating saturated steam at a pressure stage of 12,500 kPa from 328 °C to 531 °C by cooling down process gas from 723 °C to 355 °C.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

High performance cartridges and heating elements are excellently suited to direct heating of all kinds of tools. Area, ring and barrel heaters are suitable for heating boilers and moulds, tools, die plates, machine parts and a range of other purposes. They can be manufactured individually to size, voltage and output specifically for your application. High performance cartridges are suitable for tool heating in the many different fields in which a specific compatible operating temperature is required. High performance cartridges are essential in the thermal machining process field. High surface loadings facilitate a correspondingly high performance in a small installation area, at operating temperatures of up to 750°C at the heating cartridge jacket. We produce diameters between 6 mm and 45 mm to order. Different types of feed also allow high performance cartridges to be matched to the relevant installation situation.

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems up to 1000 kW. With booster technology for an increase lifetime. The Premium Line consists of 6 different units for the neutralisation of acidic condensates of gas condensing heating units up t0 1000 kW Neutrakon® N35 – up to 35 kW Neutrakon® N65 – up to 65 kW Neutrakon® N170B - up to 170 kW Neutrakon® N300B - up to 300 kW Neutrakon® N650B - up to 650 kW Neutrakon® N1000B - up to 1000 kW

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems The Neutrakon® Classic Line consists of 4 different units for the neutralisation of acidic condensates of gas condensing heating units from 25 – 300 kW Neutrakon® 01/25 – up to 35 kW Neutrakon® 02/50 – up to 65 kW Neutrakon® 03/150 - up to 150 kW Neutrakon® 04/300 - up to 300 kW

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Coating of pipings and air ducts, firing, boiler and heating systems, tanks, exhaust systems, silencers, light-metal bodies on utility vehicles Repairs to mechanically (stone impact) or chemically (de-icing salt) damaged aluminium rims Shielding of non-metallic materials, e.g. cardboard, wood, glass or plastics etc. Advantages and benefits Excellently suited for sole, decorative corrosion protection Universal protective and decorative coating for all materials Economical due to low consumption and self-cleaning spray valve High covering capacity Fast-drying

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Klöpper Therm electric flow boilers are used for generating hot water in heating units for direct heating, storage operation or for Power to Heat systems. As an alternative to other energy types in new buildings or when converting central heating units, these boilers offer a universal range of applications radiator heating, floor heating, mixed systems or bivalent operation with other energy types. Depending on the relevant operating conditions of the energy supplier, the boilers are used for direct or storage heating by utilising free electric power during off peak times.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

With its unique heat insulation, the NOVA cooking boiler not only ensures best energy utilisation but also offers uniform heat distribution across the entire boiler bottom for consistently best cooked products. For you, this means a quality increase at reducing costs. Unique heat insulation for best efficiency Uniform heat distribution ensures reproducible cooking processes Various heating types available Volume can be chosen between 300 – 1000 l Hygienic stainless steel design with antidirt edge DPK control included serially Delivery in prefabricated construction considerably shortens the assembly times

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With the effective recovery of flue gas heat, you can save up to 14% on fuel and, at the same time, reduce emissions. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 14% when using an additional downstream condensing heat exchanger — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting — Feed water cooling or combustion air preheating as alternatives to the condensing heat exchanger

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With impressively low emissions and its ability to be converted for biofuels or hydrogen, the UL-S is designed to be future-proof. — Very high efficiency for low running costs and emissions — Complete system with customer-specific equipment and future-proof technology — Extremely well proven design “Made in Germany”, highly durable and easy to maintain — Consistent steam quality for reliable supply — Custom designs available for heat recovery boilers, hybrid or superheated steam — Smart boiler control and seamless system integration with digital assistants

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Project-specific control system for optimum control of steam or hot water boilers — Maximum supply and operating reliability thanks to integrated monitoring and protection functions — Condition monitoring for consistently high system efficiency and availability of steam, hot water and heating boiler systems — Intuitive operation with graphical symbols and state-of-the-art touchscreen displays — SUC start-up, standby and shutdown system allows fully automatic high pressure steam boiler operation — Easy connection to higher-level visualisation and control systems as well as remote access via MEC Remote

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Hand-, Head- and Manhole Gasket the Safety Gasket for Steam Boilers and Vessels Characteristics The new gasket quality novaSEAL HP is made out of a high performance, temperature, corrosion and chemical resistant woven fabric. Technical parameters Temperature: t = +250 °C Pressure: p = 40 bar Main application Steam Boilers Container in round and oval shapes Gasket Characteristics Surface pressure: min. 5 N/mm 2, max. 35 N/mm 2 Recommended boiler heating gradient: max. 2 °C /min Pay attention to assembly instruction (added to each single gasket)! Suitable for Safety Gasket for Steam Boilers and Vessels Approvals Boiler water/Media resistance: TRD 611 Component designation: TÜV.D.99-001.C Form of delivery Special dimensions in cross section 15 x 8 mm or 25 x 10 mm are available on request. Standard dimensions (mm) 80x110x15x8 100x150x15x8 115x165x15x8 80x120x15x8 120x150x15x8 120x160x15x8 90x120x15x8 110x150x15x8 200x300x25x10 150x200x15x8 280x380x25x10...

Request for a quote

AQUAMETRO OIL & MARINE GMBH

Germany

Your benefits Can be mounted on the pressure or suction side of a pump Space-saving installation, because no straight inlet/outlet sections are required Flexible mounting of the meter in horizontal, vertical or inclined positions Accurate measurement result, since the reading is independent of the temperature and viscosity of the fluid Minimum failure costs due to simple function monitoring, rapid fault analysis and the possibility of simple repairs on site Areas of application To measure heating fuel consumption by oil burners (for example, in heating boilers, industrial furnaces, tar processing plants) Consumption monitoring and optimisation (ships, generators and vehicles) Flow measurement for mineral oils Optional remote processing and integration into superior systems Fuel types Fluids according to ISO 8217-2012 Heating fuel extra light/light

Request for a quote

AQUAMETRO OIL & MARINE GMBH

Germany

Your benefits Mass flow measurement Integrated temperature sensor Simple burner setting with flow rate display Simple consumption monitoring with limiting value switch Qmin/Qmax Manual dosing feature, with a resettable counter be mounted on the pressure or suction side of a pump Space-saving installation, because no straight inlet/outlet sections are required Flexible mounting of the meter in horizontal, vertical or inclined positions Accurate measurement result, since the reading is independent of the temperature and viscosity of the fluid Minimum failure costs due to simple function monitoring, rapid fault analysis and the possibility of simple repairs on site Areas of application To measure heating fuel consumption by oil burners (for example, in heating boilers, industrial furnaces, tar processing plants) Consumption monitoring and optimisation (ships, generators and large vehicles, etc.) Flow measurement for mineral oils Optional remote processing and integration into...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The secondary heating system is an integral part of the ContiRoll® and one of the decisive factors for its optimal functioning. For a perfectly dimensioned secondary heating system signicantly contributes to its eciency. The oil is heated in the boiler house to the temperature required and delivered to the primary circuit. The secondary heating station maintains the temperature in the secondary circuit to the press at set temperature by mixing the oil returning from the press that has already cooled down with the hotter oil of the primary circuit. The thermal oil transfers its thermal energy via hot platens, roller rods, steel belts to the mat to be pressed. Features Advancing temperature of the primary circuit is 280 °C Quick-acting aps for immediate re protection Heating circuits for setting the temperature distribution required by the respective process over the entire press length

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

Go ahead and brew all your own beer and let freshness sell itself! With our smallest professional brewery – the Bräutheke from KASPAR SCHULZ – you can set a new trend among customers by offering beer brewed exclusively in house. The “Bräutheke” is a complete brewery for beer production ranging from 100 hl / a up to 1,000 hl / a. The brewing technology consists of a brewhouse module, plus a fermentation and storage tank module. The custom-brewed beer can be filled into barrels and/or bottles “direct from the tank”. Alternatively, it is possible to tap the beer directly from the bright beer tank. The brewhouse module, completely pre-assembled on a framework (Two-unit brewhouse with 2.5 hl cast-out volume) with classic copper or stainless steel cladding includes: 1 mash and wort kettle, steam heated 1 mash – lauter tun / whirlpool 1 steam-heated hot water tank 1 single-stage wort cooler 1 electric steam boiler for heating the mash and wort kettle and the hot water tank

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

NEOPOR® MEANS OPTIMAL INSULATION. Neopor® comes into its own when perfect insulation is called for. The expanded foam is a version of Styropor® that contains graphite with insulation properties that are ten percent better. The very low thermal conductivity combined with high compressive resistance makes it the perfect material for technical molded parts. Storopack uses Neopor® to manufacture insulation elements for building sections such as the roof and walls as well as perimeter bases and panels for laying underfloor heating systems. Up to 70 percent of heat energy can be saved with Neopor® thermal insulation compared to homes with no exterior insulation. Storopack products made of Neopor® are used in heating and air conditioning applications for insulating boilers, pumps, and heating controls and as housing for modern home ventilation systems. The technical molded parts can be expanded to optimally fit around contours so that no heat is lost.

Request for a quoteResults for

Heating boilers - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Boilers, industrial (9)

- Petrochemical industry - installations and equipment (3)

- Heat exchangers (2)

- Waste water recycling (2)

- Heat recovery systems (1)

- Boilers, cast iron (1)

- Automatic piloting equipment (1)

- Cooking and smoke-curing equipment for delicatessens (1)

- Induction heating systems (1)

- Silicones (1)

- Wine fermentation tanks (1)

- Wood veneer - machinery and equipment (1)