- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hardness testing

Results for

Hardness testing - Import export

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

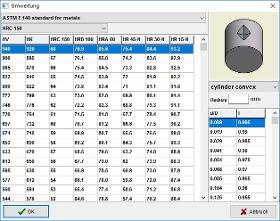

The new versions of our hardness testing applications for VMH-002 to VMH-I04 are supporting now the usage of editable conversion tables (Standard ASTM E 140: HV, HK, HRC 150, HRD 100, HRA 60, HR 45-N, HR 30-N, HR 15-N). The curvature / radius of the specimen surface can be considered now, by using a radius correction table accodring to ISO 6507-2.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The microhardness testers of the UHL VMHT series provide semi- or fully-automatic low-load Vickers or Knoop hardness testing from 1 g to 2 kg. Using brilliant Leica optics and a high valuable load mechanism with fixed weights to apply the test force, repeatable and long time stable results are achieved. Even the basic model is equipped with a user friendly motrized turret, an optical focus helper and motorized load selection.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Quality made by Siempelkamp Based on decades of experience and using state-of-the-art technology, we oer individual, comprehensive testing of your components. Key features Advantages highly-qualied sta numerous certications (see download area) individual pressure and leakage tests non-destructive testing methods (VT, PT, MT, UT and test station for RT) Innovative 3D laser and video scan measurement techniques decades of experience mobile hardness testing greatest accuracy state-of-the-art technology

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

Combining the bestThe ZHU250CL hardness tester employs the latest technology, with closed-loop control for test load application. The modern system for test load application (closed loop) stands out because of its precision. Accuracy exceeds the requirements of all relevant ISO and ASTM standards. Range of Hardness Applications: - Vickers according to ISO 6507, ASTM E384 - Knoop according to ISO 4545, ASTM E384 - Rockwell according to ISO 6508, ASTM E18 - Brinell according to IS0 6506, ASTM E10 Features: • Extremely wide test force range of 0.5 kg to 250 kg • Unique “4-plus-4” turret able to carry up to 4 lenses and up to 4 indenters simultaneously. The turret is also designed to allow testing in hard to reach positions by using a unique vertical rotation mechanism. • Variable dwell times 5-60 seconds • Ability to vary indenter approach velocity • Rockwell depth measured by the market leading Indentec transducer capable of a measuring resolution of 0.1 Rockwell point

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The ZHU/Z2.5 is the most versatile and flexible hardness testing machine in the world, it has a zwickiLine testing machine with a hardness measurement head which contains a digital travel-measuring system and an exchangeable indenter with sensor foot. It can be used with all ZwickRoell Materials testing machines and in automated applications. All indentation depth measurement method hardness tests, including Martens hardness HM, Rockwell hardness, and ball indentation hardness can be performed. Vickers depth measurement HVT, Brinell depth measurement HBT, and Knoop tests can be performed with an optical unit accessory attached to the head. This unit contains a measuring microscope and a linear displacement component, which allows the microscope and load unit to exchange positions without the need to move any components under test.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZWICKROELL GMBH & CO. KG

Germany

The ZHU 250 is ideally designed to promote an excellent quality performance and functionality. It is built with an attractive and sophisticated structure used for a very simple and easy operation, direct-viewing and more. It is considered as a versatile tester used for process loading, dwelling and unloading of the test force. It is also constructed with three hardness testing methods specifically the Brinell, Rockwell and Vickers for further variation. It is a fully automated test sequence and a highly accurate closed-loop drive system, together with excellent depth of field. The RS232 connection to testXpert® testing software enables all tests to be evaluated and documented and data transferred to quality assurance systems for further processing. The custom-made accessories tailored to a wide range of applications are also provided.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

A new dimensionThe ZHN universal nanomechanical tester is used for comprehensive, mechanical characterization of thin layers or small surface areas with the necessary force and travel resolution. This includes measuring indentation hardness, indentation modulus, and Martens hardness to ISO 14577 (instrumented indentation testing). Key Advantages and Features - Modern software, with clearly structured design - Stiff frame design with indenter axis exactly in the movement axis (no tilting moment) - High degree of modularity ZHN Applications: - Hardness and Young´s modulus to DIN EN ISO 14577 - Vickers hardness - Micro ear tests - Scratch and micro-scratch tests

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The Zwick analog shore hardness tester is a testing device with a pointer. Due to its pointer, this tester can be used to measure value that is shown after the test in hard-to-access locations. Also, it can work in tests such as soft rubber, elastometers and natural rubber to Shore A. For tough materials, these includes harder elastomers, plastics and rigid thermoplastics to Shore D. This tool can work with either material that has different hardness rating coming from shore A up to Shore D. Plus, this test device have load weight and control unit which can be easily accessible.

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

Entire testing according to EN 1957 in one test stand possible No falsification of measured values because no rearrangements or transport of the mattresses and cushion frames between the durability test and the measurement of the hardness values H and HS are necessary The system can also be used for tests according to ASTM F1566 (necessary accessories: corresponding pressure plate for hardness testing, roller for tests according to ASTM F1566) The adjustable testing table frame guarantees a high flexibility for specimens of different sizes Flexible test parameter entry (e.g. number of cycles, test load) Automatic shutdown of the machine when the pre-set number of cycles is reached Exensive testing and evaluation software Alternative: Single test stand for durability tests on mattresses, spring cores and (box spring) beds according to EN 1957/ASTM F1566 Single test stand for the hardness measurement on mattresses, spring cores and (box spring) beds according to EN 1957/ASTM F1566

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

Device details: ▪ Device is according to the standard IEC EN 60811-2-1 (Heat elongation test, tensile test) ▪ Handy, electric device for material tests in laboratories ▪ Developed to slice samples according to IEC 60811 with a thickness between 0.8 and 2.0 mm (0.04” – 0.08”) ▪ Especially for hard materials

Request for a quoteResults for

Hardness testing - Import exportNumber of results

11 ProductsCountries

Company type