- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grooving

Results for

Grooving - Import export

EWS WEIGELE GMBH & CO. KG

Germany

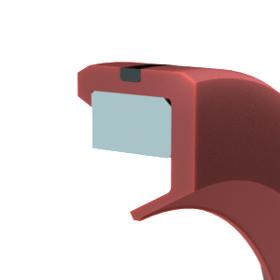

Keyway broaching on lathes is a common thing. What is new is to speed up this operation with low stress for the machine! Slot is driven by the tool turret of the machine, with the input rotary motion being converted to a translation with superimposed lift-off function. This makes programming extremely easy. The keyway broaching unit is positioned in the prepared bore – in such a way as to make the extended tappet oriented to the end position in the Z axis. The depth of the slot is produced by a constant X-feed moving between 0.04-0.08 mm/stroke. The speed of the spindle ranges between 400 R/min – 1,000 R/min, with one rotation corresponding to a complete stroke. This way, for instance, a feather key groove with a width of 6 mm and a depth of 5 mm is produced within 7.5 sec. (800 R/min and 0.05 mm feed/rotation). With this operation it is important that the chip can break at the end of the groove, that is that a cut-in or a bore exists.

Request for a quote

ROSE PLASTIC AG

Germany

Multi-compartment packaging system for carbide inserts – one-piece version with 5 individual detachable hinged boxes Versatile packaging combining single unit with multiple packaging No packing and repacking of single units necessary Each unit is reusable with hinged lid and snap-closure

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

We offer grooved seals in many different designs. There are versions without centering rim (center ring), with fixed centering rim and with loose centering rim. The area of apllications is very divers and ranges from use in fittings to high-pressure lines and systems. versions ✔ with strainer insert ✔ with flag ✔ with leakage protection ✔ with webs

Request for a quote

ROSE PLASTIC AG

Germany

Multi-compartment packaging system for carbide inserts – two-piece version with 5 individual detachable boxes Versatile packaging combining single unit with multiple packaging No packing and repacking of single units necessary Separate highly transparent lids snap into each middle and end position and provides therefore additional protection during opening/closing

Request for a quote

SPANSET SECUTEX GMBH

Germany

The proven secutex wire coil mat reliably prevents scratches and dents. The lightweight mat can be positioned quickly. Users especially rate the new rolloff stop. The individual wire rings hook firmly into the transverse grooves. The wire bundles no longer slip and an additional bundling is no longer necessary.

Request for a quote

ROSE PLASTIC AG

Germany

High-quality plastic packaging boxes for carbide inserts Many packing possibilities due to the number of compartments and post to center tools Functional and user-friendly high quality design Clear ABS material allows product presentation

Request for a quote

ROSE PLASTIC AG

Germany

Packaging boxes for carbide inserts Secure closure through center locking of lid Simple, quick press-closure of lid Lid slides open in either direction

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

The use of high-precision radial groove ball bearings is especially recommended when axial forces are supported in two directions, but the installation space makes the use of a spindle bearing pair impossible; plus when the best-possible guide for rotating components is needed, but the RPM requirements are less important. Depending upon the load capability and the installation space available, GMN provides deep groove ball bearings in sizes 60 and 62 as per DIN 625. A large selection of various cages, lubricants and covers make it possible to adapt GMN deep groove ball bearings to any application.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

With internally protected sealing lip. With O‑ring for sealing in the groove base. For high peripheral speed and increased chemical resistance

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Grooving nozzle with male thread for binding clamp

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Grooved blind rivets are suitable for riveting in blind holes in soft materials. They are used in the furniture industry, in interior fittings, in the wood and plastics processing industry, in car body construction and many more. Important: Before processing the grooved blind rivets, the drill hole diameter must be determined by testing and the minimum drill hole depth must be observed.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Single row deep groove ball bearings (Typ: 6000/6200/6300) Double row deep groove ball bearings (Typ: 4200) RDEEP GROOVE BALL BEARING Single row deep groove ball bearings (Type: 6000/6200/6300) Double row deep groove ball bearings (Type 4200) Deep groove ball bearings are wide ranging, non-separable bearings with solid outer rings, inner rings and bearing housings. These simply built products, steadfast in operation and maintenance friendly, are available as single and double row as well as sealed and open. In technical production, open bearings can have a recess on the outer ring for seals or cover rings. Due to their low moment of friction, deep groove ball bearings are suited to high speeds. Single and double row ball bearings are the most utilised anti-friction bearing. They are simple in construction, non-separable, suited to high speeds and unsusceptible in operation and maintenance. Narrow lubrication between running grooves and balls.

Request for a quote

FATH GMBH

Germany

T-Slot Nuts and Rhombus T-Slot Nuts for Aluminum Profiles for groove width: 5 - 6 - 6,5 - 8 - 10 - 11 - 12 different designs possible: — single, double — retractable, swiveling — with/without thread — ESD-capable different fixations possible: — spring plate — spring ball — pressure spring different materials possible: — steel, galvanized — plastic — stainless steel separate spring for slot nut as mounting and positioning aid available as accessory many different designs in lengths and widths with/without fixation in the delivery assortment individual designs on request

Request for a quote

FATH GMBH

Germany

Combi Hinge to hinge panels or aluminum profiles diferent Models, Materials, Sufaces, Colors combinable hinge wings: 20, 25, 30, 35, 40, 45, 50, 60 Material: Plastic PA, glass fiber reinforced, electrostatical discharging, Stainless Model: detachable, non-detachable, with/without locking lever, electrostatical discharging, centerings bolts (optional), stainless steel axis Surface: laquered, Matt nickel plated and chromated Color: black, grey, aluminum colored, further colors on request Fastening: using countersunk screws

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies. NiroSan® Adaptor press/groove

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Machining non-ferrous metals is really only different from the normal machining of steel by the use of special cutting tips and coatings.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

The short cutting systems in our sales programme cover all cutting tasks in this area.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Technical information By using our internal grooving system it is possible to machine grooves on hole diameters starting from 2 mm. Tool systems With the proven TURN-CUT 2 cutting system you can machine grooves and longitudinally turn hole diameters starting with hole diameters of 16.5mm. When using A Series tools, grooving and longitudinally turning is possible on hole diameters starting from 2 mm.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Technical information When machining bar material particular care should be taken that as little material as possible is removed as cutting forces should be minimised and costs reduced. Therefore the exchangeable disc should be selected as a function of the work-piece which is to be parted. Tool systems Das RC-System und S-System sollte als erste Wahl bei den Abstechbearbeitungen verwendet werden. Die Schneidplatten wurden so gestaltet, damit der Span schmäler als die abzustechende Nut ist und ein optimaler Spanablauf gewährleistet werden kann. Das Z-CUT-DUO System ist bedingt durch die Doppelschneidplatte auf eine bestimmte Stechtiefe begrenzt.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Technical information Axial grooving is among the most technically difficult machining process in the whole field of metal removal. In this process the chip, once removed, must overcome not just the shaping of the material but also the circular movement. It is particularly important that the machining should always commence at the outer diameter of the axial groove as tool stability is in direct proportion to the diameter. It is preferable for the tool to be used underneath the work-piece so that the chips can fall downwards without obstruction. Tool systems The S System is a modular tool system which offers innumerable possibilities to the user. The cutting tips for this system are ground to a sharp edge and produce an excellent surface quality. It goes without saying that the cutting tips can be supplied with all required corner radii. The RC System is screw clamped; the cutting tip is securely clamped into position so that it cannot fall out. When rough turning, grooving depths of up to 100 mm are standard. When turning larger diameters we are also able to achieve grooving depths of 150 mm.

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

solid carbide V-grooving end mill: with double flute, right-hand cutting, for champfering and deep groove work, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

fine-grain solid carbide V-grooving end mill: with double flute, upcut spiral

Request for a quote

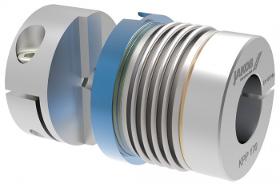

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• several hub variants with a backlash free nose groove principle • blind assembly (plug in) possible - backlash free • sturdy whole metal version for temperatures up to 200°C • Torque range: 10 - 600 Nm • Shaft diameter: 6 - 70 mm

Request for a quote

IPF ELECTRONIC GMBH

Germany

For many tasks in the field of automation technology, it is necessary to recognize the motional processes in pneumatic and hydraulic cylinders and to detect the position of the piston with precision. For this, magnetic cylinder sensors are used.

Request for a quote

IPF ELECTRONIC GMBH

Germany

For many tasks in the field of automation technology, it is necessary to recognize the motional processes in pneumatic and hydraulic cylinders and to detect the position of the piston with precision. For this, magnetic cylinder sensors are used.

Request for a quote

IPF ELECTRONIC GMBH

Germany

For many tasks in the field of automation technology, it is necessary to recognize the motional processes in pneumatic and hydraulic cylinders and to detect the position of the piston with precision. For this, magnetic cylinder sensors are used.

Request for a quoteResults for

Grooving - Import exportNumber of results

30 ProductsCountries

Company type