- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gears for pumps

Results for

Gears for pumps - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These accessories are used for mechanical valves.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Valve machined parts.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

BÜHNEN GMBH & CO. KG

Germany

The HB 5010 is a hot melt adhesive tank system with gear pump, especially for manual applications. Together with the hand gun HB 910, the tank system is ideally suited for all bead or spray bonding. The construction of the simple menu navigation of the control unit is so user-friendly that the intuitive operation of the device is possible even for untrained personnel. The extremely resilient plastic housing has a dirt-resistant paint finish. The modular structure of the system increases the ease of maintenance and ensures good accessibility of the parts when servicing. A filter change is possible without additional disassembly. A conveyor system with gear pump ensures a constant volume per unit of time. The simple design of the pump makes it robust and inexpensive. The construction of the pump also enables the processing of polyamides up to 210°C. Up to 2 heatable hoses can be connected. In combination with application heads, automation of simple tasks is possible.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Gear pumps with magnetic coupling The magnetic coupling is equal to contact-free drive and seal. Magnetic coupling pumps are used if critical media has to be transported. The seal ensures that the pumps work 100% securely and without leaking. The magnetic coupling is particularly ideal for hazardous substances that should not escape into the enviroment. The coupling is hermetically sealed and can be designed with different sensors for monitoring and in different variations and materials. A magnetic coupling is used in combination with a chemical pump by default.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

EXTRU - Melt pump for extrusion and pressure increase of medium to high viscosity media. The extrusion gear pump is mainly used in combination with extruders or kneaders. It reduces the natural pulsation of the extruder and compensates for fluctuations in delivery, especially in single screw extruders. The extrusion pump is used as a melt pump. It builds up the required feed pressure, which is needed for the downstream die. The pressure build-up in the gear pump can be much more efficient than in the extruder itself. The extruder is relieved by using an extrusion pump. Furthermore, considerably less energy or heat is introduced into the polymer. The melt pump thus contributes to conveying the product as gently as possible. The EXTRU is indispensable for the production of precise films or micro pellets.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

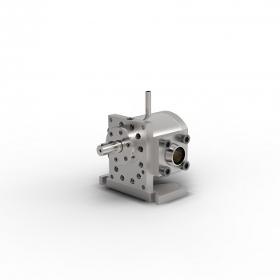

Stainless steel metering gear pump for the delivery of chemical raw materials for the production of pharmaceutical products. CHEM metering pumps are also used to pump isocyanate, sulphuric acid, polyol or essential oils. With the appropriate combination of materials, many critical applications can be realized and a variety of low-viscosity fluids can be pumped. The range of applications extends from classic transfer and metering tasks in the chemical and pharmaceutical industry to the pumping of monomers, oligomers and prepolymers in polymer production. These chemical pumps are suitable for even the most difficult tasks and impress with their reliability and dosing accuracy in both vacuum and high-pressure applications. Typical applications for this pump type are in the chemical, cosmetics, food, petrochemical and polymer industries

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The CHEM gear pump series was developed especially for the requirements of the chemical industry. The series is used for pumping and transferring low to medium viscosity media. The CHEM series is extremely flexible in its design and areas of application. Technical details: — Suction pressures from vacuum up to 15 bar and suction pressures with magnetic coupling up to 25 bar — Delivery volume 1.28 cc/rev to 12,000 cc/rev — Temperatures up to 300 degrees — As special pumps for the chemical industry according to customer specifications — Viscosities up to 1.000.000 mPas

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Chemical pump with electrical temperature control. The CHEM series is designed to be easy to maintain. Separate pump covers allow a quick inspection of the inner workings from both sides of the pump. To adjust the axial clearance we use shims which can be varied according to process parameters. Chemical pumps of the CHEM series are offered as standard versions with components made of stainless steel or as special versions with coated or ceramic materials. To bring or maintain the pump at process temperature, two temperature control variants can be used, electric and hydraulic.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Witte chemical pumps are used as dosing pumps for a variety of fluids. Pumps of the CHEM series are designed and assembled exclusively at the Tornesch site, thus guaranteeing highest reliability and quality. For all our series we offer a comprehensive spare parts service on request. In addition, we also install the pumps directly at our customer's plant. Dosing pumps of the CHEM series are extremely flexible in their design and can be offered in various variants and equipment thanks to a modular system. Differential pressures up to 120 bar, suction pressures vacuum up to 15 bar Temperatures up to max 500 °C in combination with a magnetic coupling. Viscosities up to 1.000.000 mPas or higher Components made of stainless steel, ceramic and special materials Flow rates from 20 l/h to 170,000 l/h

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump specially designed for use in the production of medical tubing made of TPE, PE or PA. The melt pump is installed downstream of the extruder in the extrusion process for pressure build-up and constant delivery of the melt to the die. It is particularly important for medical tubing that the wall thickness and quality is absolutely constant and uniform.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Chemical pump hydraulically temperature controlled for a wide range of applications. This ranges from organic and inorganic chemicals to food oils, polymers and pharmaceutical products. A wide-ranging modular system provides optimum material combinations for corrosive or abrasive media.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for the production of HDPE / LDPE / LLDPE. Melt pumps of this type are used in the production and processing of HDPE / LDPE / LLDPE. The EXTRU series is exkat adapted to the requirements in these processes and thus works with highest precision. Special serrations allow an almost pulsation-free conveyance of the melt, which guarantees a constantly high product quality.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for the production of medical flow. Melt pumps of this type are used, among other things, in the production of medical fluids, such as those used in respiratory masks. The melt-blown fluid can be used in many different ways in protective masks or filters. The EXTRU series is exkat adapted to the requirements of the melt-blow process and thus works with highest precision.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The POLY-AT design offers exceptional flexibility when it comes to installations beneath the polymer melting reactor. Customers can choose from three different flange geometries to ensure they are always benefiting from the best combination of reactors and pump flanges from both a technical and economical perspective. The new gear geometries facilitate differential pressures of up to 320 bar for selected pump sizes. What’s more, the new design is rounded out with the usual variety of different material combinations. The most common of these combinations has to be a stainless-steel or carbon-steel housing with tool steel or aluminium-bronze friction bearings.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUTZ PUMPEN GMBH

Germany

Eccentric screw pump tube B70V-SR Industrywith reduction gear for electric motors For pumping highly flammable liquids and for use in "Zone 0", use Pump tubes with mechanical seal (GLRD), cardan shaft (GW) and PTFE stator. The Eccentric screw pump B70V-SR 12.1 (with reduction gear) in the industrial version is suitable for pumping water-like to highly viscous media with and without fibrous or solid materials. Depending on the application, various compressed air and electric motors are available, which you can combine with the Pump tube at any time. This gives you flexibility at all times and saves important resources. * PTO shaft versions also available in special immersion depths of 500 - 2000 mm * Media examples: viscous mineral oils, resins, emulsions, paints and many other thick materials * Uniform volume flow * Easy and fast cleaning * Gentle, low-pulsation product delivery * Low wear * Ideal for mobile use

Request for a quote

LUTZ PUMPEN GMBH

Germany

The eccentric worm-drive pump B70V-SR (with reduction gear) in PURE design is suitable for pumping water-like to highly viscous media with and without fibres or solids. Depending on the application, various electric and compressed air motors are available, which you can combine with the pumping unit at any time. This gives you flexibility at all times and saves important resources. * Also available in special immersion depths * Examples of media: viscous cosmetic products, foodstuffs, etc. * Uniform volume flow * Gentle, low-pulsation product conveyance * Low wear and tear * Ideal for mobile use * Approved in accordance with ATEX Directive 2014/34/EU, category 1/2

Request for a quote

FLUX-GERÄTE GMBH

Germany

Pre-assembled progressive cavity pump kit with progressive cavity pump F 570 and planetary gear for industrial applications to pump thin to medium viscous media up to 30.000 mPas out of 200-l drums and IBCs. The positive displacement pump works smoothly at a constant pressure and ensures a gentle, pulsation-free pumping. Comprising Progressive cavity pump VISCOPOWER F 570 in 1000 or 1200 mm, Commutator motor F 457, Stator housing, Stator, Hose, Discharge spout, Hose connection and compression gland.

Request for a quote

FLUX-GERÄTE GMBH

Germany

Pre-assembled progressive cavity pump kit with progressive cavity pump VISCOPOWER F 570 and planetary gear for food and pharma to pump thin to medium viscous media up to 25.000 mPas out of 200-l drums and IBCs. The pump is especially designed to meet the specific requirements of the food, cosmetic and pharmaceutical industries and works with little turbulences, at constant pressure and ensures a smooth, pulsation-free pumping. Comprising Eccentric worm-drive pump F 570 in 1000 or 1200 mm, Commutator motor F 458-1, Stator housing, Stator, Hose, Discharge spout, Hose connection and compression gland.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The hose press S2 is available in various variants, perfectly adapted to your needs: S2 - Standard S2 M H Ecoline - Manual, developed pump S2 M Ecoline - Manual S2 P - Pneumatic S2 A - Automatic S2 DC -different voltages possible The new S2 M Ecoline H helps reduce machine downtimes The S2 M Ecoline crimper from UNIFLEX weighs only 30 kg and is the ideal device for the on-site repair of hydraulic hoses in construction and agricultural machinery. Hose connections up to 1" (for 2-part fittings) or 1 ¼" (for single-part fittings) can be established easily and safely – without the need for lubrication, and protected by a sturdy frame. In high-gear mode, the new two-stage pump of the S2 M Ecoline H line works three times faster than previous models. Thanks to the retractable lever, the compact device takes up only minimum space when stowed away.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Stainless steel gear pump for the delivery of alcohols, isocyanates or gels. The exact volumetric dosing of this series guarantees a low-pulsation and constant flow rate. Due to its compact size and high precision, the CHEM MINI is ideally suited for use in laboratories. Parts in contact with the medium can be made of stainless steel or ceramic materials. The series is available in sizes from 0.2-9-5.5 to 2.95-14-28, other sizes are also available on request. The range of application covers classic transfer and dosing tasks in the chemical and pharmaceutical industry. Due to decades of design experience and optimum material selection, this pump type is suitable for even the most difficult tasks and convinces by its reliability and dosing accuracy in vacuum applications.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Testing has never been easier and quicker. With the P300, you can perform precision tests of hoses of up to 2500 mm in length and with pressures up to 1000 bar. Test up to 120 hoses per hour, making use of 4 parallel test lines and our quick-clamping system. You can choose between automated and manual setup mode. The P300 comes with a number of standard features such as an internal lighting and a portable power aggregate, and caters for individual test logging. •Testing of up to 120 hoses per hour •4 parallel test specimen •Combination of two test chambers (mirror arrangement) •Fast workflow thanks to separately running test chambers (for alternate setup and testing) •Quick-clamping system holding up to 4 hoses for parallel testing with customised settings •Internal lighting system, adjustable machine feet and top-quality internal gear pump •Quick changeover between automated and manual setup mode •Separate portable power aggregate (with 2m connecting cable)

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

4-hole Screw-in BSPP Threaded Flange (Flat Style) GP-FL-LK-G ▪ Working Pressure: 180 bar ... 250 bar ▪ Ø LK: 30 mm ... 72,5 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: CrVI-free 4-hole Butt Weld Flange GP-LK...-ST.../...#K ▪ Working Pressure: 250 bar ▪ Ø LK: 30 mm ... 56 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: blank, oiled 4-hole Fitting Flange with BSP 60° Cone Connector (acc. to BS 5200) GP-LK...-AG...#K ▪ Working Pressure 250 bar ▪ Ø LK: 30 mm ... 56 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: CrVI-free 4-hole Screw-in BSPP Threaded Flange GP-LK...-G...#K ▪ Working Pressure: 250 bar ▪ Ø LK: 30 mm ... 56 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: CrVI-free

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

4-hole Flange Connection with 24° Cone Connector (acc. to ISO 8434-1 / DIN 2353) GP-LK-L/S ▪ Working Pressure: 315 bar ... 250 bar ▪ Ø LK: 35 mm ... 55 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: ZnNi 4-hole 90° Flange Connection with 24° Cone Connector (acc. to ISO 8434-1 / DIN 2353) WP-LK-L/S ▪ Working Pressure: 100 bar ... 315 bar ▪ Ø LK: 35 mm ... 55 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: ZnNi 3-hole 90° Flange Connection with 24° Cone Connector (acc. to ISO 8434-1 / DIN 2353) WP-3-LK-L/S ▪ Working Pressure: 160 bar ... 250 bar ▪ Ø LK: 30 mm ... 40 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: ZnNi

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

3-hole 90° Screw-in BSPP Threaded Flange WP-3-LK-G ▪ Working Pressure: 300 bar ▪ Ø LK: 26 mm ... 56 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: ZnNi 4-hole 90° Screw-in BSPP Threaded Flange WP-LK-G ▪ Working Pressure: 250 bar ... 300 bar ▪ Ø LK:35 mm ... 55 mm ▪ Materials: S355J0or equivalent ▪ Surfaces: ZnNi 3-hole 90° Screw-in BSPP Threaded Flange(Aluminium) WP-3-LK-G-W50 ▪ Working Pressure: 180 bar ▪ Ø LK: 26 mm ... 51-56 mm ▪ Materials: Aluminium [EN AC-Al Si9Cu(Fe)] 4-hole 90° Screw-in BSPP Threaded Flange (Aluminium) WP-LK-G-W50 ▪ Working Pressure: 180 bar ▪ Ø LK : 30 mm ... 55 mm ▪ Materials: Aluminium [EN AC-Al Si9Cu(Fe)]

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

Product characteristics of the Disc clutches The shifting clutches mostly serve as a connection that can be activated or disconnected between the power and work units, such as the gear and pump, or in similar installation situations. The disconnection is achieved via the system's existing media supply. (hydraulics, pneumatics) Areas of use of Disc clutches The disc clutches are used in mobile applications, agricultural and forestry machines, sweeping machines and many other areas in mechanical engineering.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Preparation unit tanks for first and second phase Storage tank equipped with flowmeter system Homogenizer Sanitary centrifugal pump Mechanical filter Filter platform collector Pipes and fittings All joints are tic and orbital welded, polished and treated Stainless steel Teflon check valves, Pipe tri clamp joints. The production capacity varies depending on the type of products Gear pump cycle of the feeding device can speed up product forming and rapid discharge Semiautomatic weigh filling machine for gallons. Monoblock filling and capping machines feeding and collecting tables HMI and SCADA with touch screen system. Available certification up on your request UL, CE, GMP, FDA, ASME.

Request for a quoteResults for

Gears for pumps - Import exportNumber of results

41 ProductsCountries

Company type