- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas heat exchangers

Results for

Gas heat exchangers - Import export

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

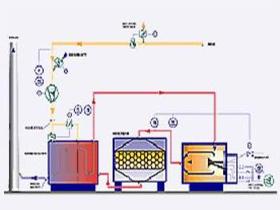

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quote

APROVIS

Germany

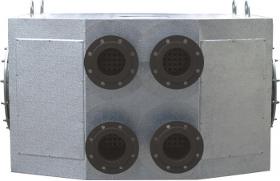

What you can expect from an APROVIS process gas heat exchanger: - Suitable for low and high temperature ranges - Operating pressures up to 160 bar - Compact design for use in confined spaces - Suitable for a wide range of gases - Implementation of customised solutions

Request for a quote

APROVIS

Germany

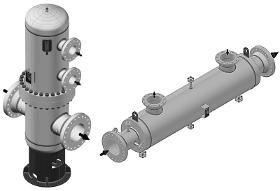

What you can expect from APROVIS exhaust gas heat exchangers: - Efficient hot water generation in combined heat and power plants - Heating of thermal oil as an energy source - Individual solutions and compact designs - All the main components for the exhaust gas section and gas treatment are combined under one roof: proprietary products developed in-house - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

APROVIS

Germany

* Exhaust gas heat exchangers * Steam generators * Silencers * Oxidation and three-way catalytic converters * SCR catalytic converters/Diesel SCR catalytic converters * Diesel particulate filters * Chimneys

Request for a quote

APROVIS

Germany

* FriCon - gas dehumidification * Gas heaters * ActiCo - activated carbon filters * Gas compressors * Process gas heat exchangers

Request for a quote

APROVIS

Germany

What you can expect with an APROVIS FriCon: - FriCon systems are ready for connection - The FriCon removes the moisture from the process gas by dropping below the dew point temperature - FriCon gas heat exchangers operate at elevated pressure, ambient pressure and negative pressure - Condensate formation in downstream gas lines is avoided - Suspended matter is separated - The FriCon is available in different sizes and designs

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

THERMO-GAS Heat Exchangers work optimally if the constant flow of gasses into the heat exchanger is guaranteed. In case of unfavourable assembly conditions, we have made tests and measurements so far in order to optimise stream conditions. Due to the increased requirements on the performance of heat exchangers as well as expanded application areas it has become necessary to achieve optimised results already in the planning phase. This is done by means of a CAD-based simulation which enables the very exact predicition of stream conditions. The performance opportunities of our heat exchangers are used at the best as a result of appropriate installed equipement for flow duct. We would be pleased to provide you with our knowledge also beyond the heat exchanger technology. The precise project In case of a plant for catalytic combustion, the connecting hood to the heat exchanger was significantly shortened due to the assembly of a THERMO-AWT 3-Way Stop valve. After this

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems The Neutrakon® Classic Line consists of 4 different units for the neutralisation of acidic condensates of gas condensing heating units from 25 – 300 kW Neutrakon® 01/25 – up to 35 kW Neutrakon® 02/50 – up to 65 kW Neutrakon® 03/150 - up to 150 kW Neutrakon® 04/300 - up to 300 kW

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems up to 1000 kW. With booster technology for an increase lifetime. The Premium Line consists of 6 different units for the neutralisation of acidic condensates of gas condensing heating units up t0 1000 kW Neutrakon® N35 – up to 35 kW Neutrakon® N65 – up to 65 kW Neutrakon® N170B - up to 170 kW Neutrakon® N300B - up to 300 kW Neutrakon® N650B - up to 650 kW Neutrakon® N1000B - up to 1000 kW

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KME series was developed as a wet-installed centrifugal immersion pump for stationary use in tanks and basins. The direct-coupled pump with plain bearings is suitable for pumping and circulating neutral and chemically aggressive liquids in the chemical industry and process engineering, in electroplating and surface technology, in washing systems and water treatment plants, for sump drainage in industrial and municipal waste disposal plants or as a circulation pump in gas scrubbers and heat exchangers. * with various plain bearing designs * available in immersion depths from 600 - 1500 mm Features & Advantages * Compact dimensions * Abrasion resistant material combinations possible * Extremely low-vibration and low-wear operation * All wetted parts made of corrosion resistant plastic * Self-centering alignment in the bearing shell

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With the effective recovery of flue gas heat, you can save up to 14% on fuel and, at the same time, reduce emissions. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 14% when using an additional downstream condensing heat exchanger — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting — Feed water cooling or combustion air preheating as alternatives to the condensing heat exchanger

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the extraction of the feed water/condensate — Consumes less power, more convenient to operate — Speed-controlled version for increased flue gas heat exchanger efficiency — Redundant pump for maximum reliability of supply — Preassembled for fast installation Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For continuous feed water control — Increased efficiency of flue gas heat exchangers — Fewer pump circuits — Constant boiler water level — Minimum flow rate for cooling the feed pump is assured Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Büttner's fash-tube dryers are most versatile and extremely ecient. The dryer systems are used for drying material having high levels of surface moisture or a specic surface area. They are, for example, used to pre-dry wood akes before they are conveyed into drum dryers. Flash tube dryers are also used as the principal dryers for drying bres to be used in MDF production. For many years Büttner's ash tube dryers have been in operation successfully in many dierent industrial sectors all over the world Features Water evaporation of up to more than 70 t/h per unit depending on the product Drying within just a few seconds, the material is then already mechanically separated and conveyed to the downstream drum dryer. Flash tube dryers may be heated in many dierent ways, for example: Flue gas from grate ring Büttner gas line burners Hot gas from gas turbines or gas motors Indirectly by heat exchangers for steam or thermal oil Any combination of the heating methods mentioned above

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

TUBE BUNDLE HEAT EXCHANGER, TYPE VEV/VEV-L/VEV-ex Gas / Water; horizontal / vertical CHARACTERISTICS Optimal load case design Flow stream optimized design Vibration-optimized design OPTIONS Customer-specific design for various design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) Design according to TEMA Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Customer-specific nozzle arrangement GENERAL Heat exchangers (heat exchangers) heat gas for a subsequent system requirement or to counteract the Joule-Thomson effect. For example, For example by pressure reduction in a gas-pressure control. Heat exchangers can also be determined in the reverse mode of operation as coolers. The design is carried out as a steel welded construction in vertical or horizontal design.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Under defined conditions, the catalytic thermal oxidizer (CTO) is an economical alternative for cleaning organic air pollutants (including VOCs). The system has proven to be particularly efficient when handling identifiable and consistent pollutant loads. In general, exhaust gases containing silicon and phosphorous cannot be treated. Under defined conditions, the Catalytic Thermal Oxidizer (CTO) is an economical alternative for cleaning organic air pollutants. The procedure is based upon the fact that under suitable conditions, even low amounts of volatile pollutants can be burnt without producing residue. This process would have required a high amount of heat energy. Therefore a catalyser and a heat exchanger are installed. The tubular heat exchanger installed behind the catalyser uses as much energy from the hot clean gases as possible in order to heat up the cold raw gases. The job of the catalyser is to decrease the amount of energy required to convert the pollutants without being depleted during the reaction. The raw gas loaded with pollutants is then forced into the heat exchangers of the CTO by the process fan. Here the raw gas is pre-heated by the hot clean gas. When required the burner heats up the exhaust gas further in the combustion chamber to the ignition temperature of the catalyser. In the catalyser the pollutants are converted into non-polluting CO2 and H20 vapour. After the catalyser, the clean gas is forced into the heat exchanger tubes. Along the way through the heat exchanger tubes the raw gases is heated and cooled. Eventually the clean gas leaves the system via the clean gas socket.

Request for a quote

ANTHERMO GMBH

Germany

Know-how for special applications There are applications with very special requirements for the heat exchanger. Due to its decades of experience, Anthermo GmbH has the necessary know-how to be able to build special heat exchangers for special applications. So every year we build numerous heat exchangers that are a bit off the standard. Dimensioning with EDP programs With the help of EDP programs, Anthermo GmbH is also able to dimension and technically design special heat exchangers. The technical design and dimensioning is strictly based on the specifications and requirements of the customer. After the design, a three-dimensional CAD model is created. The CAD drawing approved by the customer forms the basis for production with the most modern IT-supported production systems.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of liquids Tube coil heat exchangers (so-called tube cooling coil heat exchangers) are generally used to control the temperature of liquids. This system can also be used to heat or cool liquids in a controlled manner. Due to their special shape, pipe coil heat exchangers are sometimes also called hairpin heat exchangers. Inexpensive applications The simple and solid structure enables it to be used in cost-effective applications. Coiled tube evaporator systems are ideally suited for brine and glycol applications. Classic variant Coiled tube evaporator systems are a classic and proven variant in the field of heat exchanger systems. Coiled tube heat exchangers are often used in ice storage systems or in the production of cold water units. In ice storage systems, coils can be used to achieve an even build-up of ice around the coils.

Request for a quote

ANTHERMO GMBH

Germany

Tubes wound into a spiral shape Coaxial heat exchangers consist of two or more pipe coils, which are routed into one another and wound up in a spiral shape. The primary medium runs in countercurrent to the secondary medium. Fast temperature exchange This countercurrent design achieves a very rapid temperature transition with high efficiency between the liquids. Due to the spiral shape, the rapid temperature exchange between the liquids is achieved in a very small space. No cleaning or maintenance required Another advantage is the encapsulation of both liquids from environmental influences. There is practically no cleaning or maintenance effort due to pollution from the environment. The coaxial heat exchanger also does not require any seals that require maintenance. Condenser or evaporator function Coaxial heat exchangers can be used for both condenser and evaporator functions.

Request for a quote

ANTHERMO GMBH

Germany

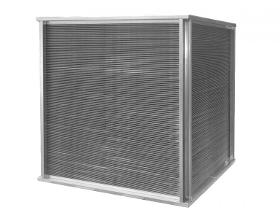

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-water heat exchangers for industrial use Three types of air-water heat exchangers Three different designs o air-water heat exchangers The Anthermo GmbH delivers three different designs of air-water heat exchangers: Finned tube heat exchangers Lamella heat exchangers Straight tube heat exchangers These heat exchangers are designed in a way, that inside the tube water or another liquid circulates. The air flows around outside the tubes or the fins/lamellas. The connection between the fins and the tube is used to enlarge the space for heat transfer between the liquid and the gas fluid. The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-water heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Temperation of fluids Pillow plates are used everywhere where liquids must be temperated. In dependence of application the liquids can be cooled or heated. Cause of this wide range of applications pillow plates are used in the process industry, in the cooling industry and in a lot of other industries. Pillow plates are also know as heat exchanger plates, evaporator plates, cooling plates /sheets and thermo plates / sheets. Pillow plates as air-/water-heat exchanger Additionally to the temperation of liquids pillow plates are also used as air-/liquid heat exchangers. In case of polluted or wasted air and if there are high demands for cleaning, more and more pillow plates are used as air-/water-heat exchanger. The large exchange surface and the good possibilities for cleaning are important features for this type of heat exchanger.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS high-temperature heat exchangers: - Transfer to water / thermal oil / air - Abrasion protection for abrasive components in the flue gas or product gas (e.g. wood gas) - Implementation of individual solutions (e.g. with regard to available space, thermal performance) - Use of various high-temperature stainless steels according to the application in question - Own measurements on site

Request for a quote

KELVION HOLDING GMBH

Germany

The wide range of product portfolio of coils with different tube diameters, tube patterns, fin profiles, materials and options allows us to customize our coils for any specific application and fluids: air heaters, air coolers, condensers and evaporators for HVAC and various industrial applications. Kelvion heat exchanger coils are manufactured with copper tubes and aluminum or copper fins. The fins are equipped with special profiles developed at our R&D department enhancing heat transfer and keeping pressure drop at a moderate level. The customized fin spacing is achieved by collars which also provide the contact between the fin block and the tubes. Mechanical expansion of the tubes guarantees a perfect bond between the fins and the tubes leading to maximum heat transfer between both fluids.

Request for a quoteResults for

Gas heat exchangers - Import exportNumber of results

36 ProductsCountries

Company type