- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas analyses

Results for

Gas analyses - Import export

WITT-GASETECHNIK GMBH & CO KG

Germany

Cordless handheld oxygen or combined oxygen and carbon dioxide analyser for checking modified atmospheres in food packs. The ideal instrument for portable, faster and accurate sample tests at the packaging machine, in stores or in laboratories. OXYBABY® is a cost effective mobile alternative to tabletop / fixed analysers for welding and food technology. It offers all benefits of modern technology quickly and easily by option. For example: Bluetooth for wireless communication and an integrated barcode reader. Ensure that the quality of packaged product is maintained (HACCP), and thus guarantee continued customer satisfaction. The ideal instrument for sample tests with a minimum sample gas requirement, allowing the smallest of modified atmosphere packages (MAP) to be tested. Information of internal pressure in the package via pressure indication.

Request for a quote

RIDZEWSKI GMBH

Germany

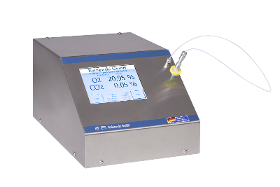

The EPC Spot is our measuring device for a random check of the gas levels of O2/CO2 in packaging or packaging machines. A sample is taken by a special needle. Due to the small amount of gas the analyser needs for the measurement, blister packs or ampoules can also be tested. As a user, you can enter several limit values for different products in the device. The result is then additionally visualised in red or green. All measurements are stored in the device and can be further processed in various ways. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages

Request for a quote

RIDZEWSKI GMBH

Germany

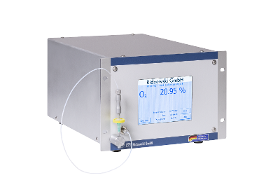

The EPC VM is our measuring device for monitoring O2/CO2 in packaging machines. In addition to continuous measurement of the gas atmosphere, spot measurement of individual packages is also possible. The functionality is the same as with our Zr-Ox EPC spot analyser. Once set, the analyser can also control the gassing of the machine. Advantages - Over 20 years of experience in development and optimisation - Top response time and short heat-up phase - Two different sizes for added flexibility - Long average life components - Digital measurement data logging - User-friendly filter change - 5.7 inch touch screen - Intuitive menu navigation - in many languages - Various RS232 protocols that can be changed in the unit for communication with different soldering, packaging soldering, packaging machines, analysers or other equipment and processes - Operation for user and administrator in different levels

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The DK32/34 is a variable area (VA) flowmeter for measuring low flow rates of liquids and gases. The tried and tested meter is particularly suitable for flow monitoring and dosing in gas analyser systems or on purge panels. Due to its robust all-metal design it can also be used in difficult process conditions with temperatures up to +200°C / +392°F or pressures up to 400 barg / 5800 psig. It is available with a metering valve as standard to accurately set the flow value. The DK32/34 operates without auxiliary power supply. The device just features a local indication with two optional MIN/MAX limit switches (NAMUR) or a reed contact. To provide constant flow rates in case of variable inlet or outlet pressures, the VA meter is also available with flow regulators. It comes with horizontal or vertical process connections for NPT or G thread and many other connection options. The VA meter has various approvals for hazardous areas.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The DK46/47/48/800 is a variable area (VA) flowmeter for monitoring and adjusting extremely small flow rates of liquids and gases. It is thus particularly useful for sample flow monitoring in analyser systems and gas chromatographs or measuring liquids and gases in laboratories and pilot installations. The purgemeter operates without auxiliary power supply and is available with different glass tube and installation lengths from 90 to 325 mm / 3.55 to 12.8". The medium is visible and the flow value can be read directly off the scale at the height of the float. The glass flowmeter can be provided with max. two limit switches (NAMUR) or a 3-wire digital output. For precise setting of the flow value, the VA meter features a needle valve. The DK 46/47/48/800 is also available with a differential pressure/flow regulator to provide constant flow rates in case of varying inlet or outlet pressures. The device has approvals for use in hazardous areas.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

Modular equipments for technical training at engines under realistic operating conditions: under load at the engine dynamometer. Applications depending on scope of delivery: torque, power = f(speed), specific consumption sfc = f(speed, power) (gravimetric, selectable automatically). Above tests can be carried out in different ways: conventionally or supported by the test bed's MP Computer or with automatic documentation by directly printing or by PC thermal balance (PC required), real function of a transmission (automatic transmission only with PC), p-V-diagram (PC required). Functions of engine and engine control depending on the load may be demonstrated by using motor analysers, exhaust gas analysers and further measuring instruments. Model-specific error-switch boards are extending the demonstration varieties and are enabling a practical error diagnostics. Comparison of different engines under a certain aspect within one lesson.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

WITT offers high-quality gas mixers / gas blenders and gas metering systems for two or more gases, for high flow rates and highly fluctuating gas withdrawals. You can choose between various options: According to your requirements, WITT gas mixers / gas blenders are available for nearly all technical gases and flow rates: for the optimal gas mixture for welding applications, the required gas concentration for food packages (modified atmosphere packaging = MAP) or the production of synthetic air for medical applications. State-of the art mechanical or electronic gas mixing systems provide accuracy and process safety. You can also control your gas mixing systems conveniently via Intranet, Internet or mobile devices. Combinations of WITT gas mixers / gas blenders with other WITT quality products such as gas analysers are also possible. They can be manufactured as complete system solutions.

Request for a quote

HELANTEC GMBH

Germany

The HELOX 4 has been a proven test instrument for quality control of IG units for more than 30 years. The analyser is preferred by test institutes and the central labs of the insulated glass manufacturers. A paramagnetic measuring cell that selectively measures the residual oxygen, and which consequently is the primary measurement method, is used as the measuring technology for this analyser. This has the advantage that the user does not need to know which gas type is in the IG unit. On the display the gas concentration of the gas sample is shown. A rechargeable battery can be integrated as an option, which enables the devices to also be used directly on the construction site. A sample is injected with a gas syringe. This offers the advantage that only minimal gas quantities are required and you can check the function of the gas analyser yourself.

Request for a quote

HELANTEC GMBH

Germany

The GAS TESTER is our lowestprice entrylevel model for monitoring gas concentration. Naturally we have installed our proven analysis technology in this product as well. Features reliable concentration measurements compact and handy design easy operability argon and krypton use optional data storage Only a small quantity of gas is required. Sampling is executed with a special gas supply pump. The GAS TESTER is suitable for quality control of IG units with argon or krypton as the filling gas. If you desire to also analyse other gas types or gas mixtures, you should chose one of our other analysers.

Request for a quote

HELANTEC GMBH

Germany

The RAPIDE L200 is based on the HELANTEC fastfill technology and is the entrylevel model of the RAPIDE L series. The capacity with one filling line is approximately 300 units1). It is equipped with modern, progressive technology and enables efficient gas filling with reliable gas concentrations. This is measured continuously during the entire filling process via an integrated gas analyser. As soon as the set gas concentration is reached the filling process is ended automatically. Synchronisation of the filling and suction process also enables troublefree filling of large IG units. The handy device is well suited for changing implementation sites. The HELANTEC RAPIDE L200 also convinces with its extremely favourable priceperformance ratio. Are you looking for higher capacity and shorter cycle times? If so, consider our gas filling systems, RAPIDE L500 and RAPIDE L900.

Request for a quote

HELANTEC GMBH

Germany

The SMART 150 is a small and handy gas filling system, equipped with the proven and high quality HELANTEC gas filling technology components. It enables a reliable filling process with easy operation. The capacity is configured for 150 units1) with one filling line. The SMART 150 gas filling system is suitable for occasional gas filling production of sample units smaller production facilities Gas concentration is measured continuously during the filling process by the integrated gas analyser. As soon as the set gas concentration is reached the filling process is ended automatically. Through the use of a pump, as well as the optimised filling speed, an extremely low gas consumption is realised. The SMART 150 can be used for all gases and gas mixtures that are standard in the insulated glass industry. The excellent priceperformance ratio will convince you.

Request for a quote

WI.TEC -SENSORIK GMBH

Germany

The ULTRA.sens® is the world’s first OEM gas measurement module based on miniaturized UV LEDs. The stability and lifetime of these UV-LEDs enables high-precision gas analyses down to the ppb range. By using two UV-LEDs 2 gases can be detected simultaneously. With this approach, 2 measuring ranges from ppm to Vol.-% can also be realized. In the spectral range from 200 nm to 500 nm, nitrogen oxides (NO+NO2), aromatic hydrocarbons, hydrogen sulphide, ozone, sulphur dioxide and chlorine can be reliably detected with this novel sensor platform. Applications Environmental and Process Measurement Technology (CEM) Engine development TOC analyzers Elemental analysis Industrial gas analysis Natural gas/biogas analysis Process measurement technology Biogas research

Request for a quote

WI.TEC -SENSORIK GMBH

Germany

The ULTRA.sens® is the world’s first OEM gas measurement module based on miniaturized UV LEDs. The stability and lifetime of these UV-LEDs enables high-precision gas analyses down to the ppb range. By using two UV-LEDs 2 gases can be detected simultaneously. With this approach, 2 measuring ranges from ppm to Vol.-% can also be realized. In the spectral range from 200 nm to 500 nm, nitrogen oxides (NO+NO2), aromatic hydrocarbons, hydrogen sulphide, ozone, sulphur dioxide and chlorine can be reliably detected with this novel sensor platform. Applications Environmental and Process Measurement Technology (CEM) Engine development TOC analyzers Elemental analysis Industrial gas analysis Natural gas/biogas analysis Process measurement technology Biogas research

Request for a quote

WI.TEC -SENSORIK GMBH

Germany

The ULTRA.sens® is the world’s first OEM gas measurement module based on miniaturized UV LEDs. The stability and lifetime of these UV-LEDs enables high-precision gas analyses down to the ppb range. By using two UV-LEDs 2 gases can be detected simultaneously. With this approach, 2 measuring ranges from ppm to Vol.-% can also be realized. In the spectral range from 200 nm to 500 nm, nitrogen oxides (NO+NO2), aromatic hydrocarbons, hydrogen sulphide, ozone, sulphur dioxide and chlorine can be reliably detected with this novel sensor platform. Applications Environmental and Process Measurement Technology (CEM) Engine development TOC analyzers Elemental analysis Industrial gas analysis Natural gas/biogas analysis Process measurement technology Biogas research

Request for a quote

WI.TEC -SENSORIK GMBH

Germany

The ULTRA.sens® is the world’s first OEM gas measurement module based on miniaturized UV LEDs. The stability and lifetime of these UV-LEDs enables high-precision gas analyses down to the ppb range. By using two UV-LEDs 2 gases can be detected simultaneously. With this approach, 2 measuring ranges from ppm to Vol.-% can also be realized. In the spectral range from 200 nm to 500 nm, nitrogen oxides (NO+NO2), aromatic hydrocarbons, hydrogen sulphide, ozone, sulphur dioxide and chlorine can be reliably detected with this novel sensor platform. Applications Environmental and Process Measurement Technology (CEM) Engine development TOC analyzers Elemental analysis Industrial gas analysis Natural gas/biogas analysis Process measurement technology Biogas research

Request for a quote

BLUESENS GAS SENSOR GMBH

Germany

Oxygen is essential for life. Measuring oxygen concentrations plays a central role in controlling biotechnological processes . No matter if fermentations, scale-up studies, bioproductions in lab or industrial scale, the BCP-O2 sensor determines the oxygen concentration in realtime (real time monitoring) in a very convenient way. By measuring the oxygen concentrations oxygen limitations can be avoided and conclusions to metabolic activity can be drawn. With the help of measuring the oxygen important process parameters as OTR oxygen transfer rate or respiratory quotient RQ can be determined. Using BCP-O2 simplifies process optimization in bioprocessing and makes it efficient and precise. In contrast to other sensors the BCP-O2 has in integrated automated temperature and pressure compensation and can be connected to each and every fermenter type. BCP-O2 doesn´t need a minimum flow rate and thus can be applied from small (lab) scale (e.g shake flask) up to the large industrial scale.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BLUESENS GAS SENSOR GMBH

Germany

BlueVary is a maintenance free gas analyzer for variable biotechnological applications. By selectable sensor cartridges different measuring tasks ranging from microbial, cell culture to monitoring of algae and biogas processes can be covered by just one device. The analyzer consists of a basis element with measurement places for two of the variable sensor cartridges. The third place holds a cartridge to compensate pressure and/or humidity. The integrated display ensures an overview about sensor and concentrations at any time. As already known from the forerunner analyzers BlueVary can be mounted on each fermenter from lab to production scale by using different mechanical connections without being limited by fermenter brand or manufacturer. Various data outputs are available. Annual maintenance is not necessary. In combination with the open software BlueVis the BlueVary turns into a versatile, effective tool for real-time online monitoring and optimization of bioprocesses of any kind.

Request for a quoteResults for

Gas analyses - Import exportNumber of results

19 ProductsCountries

Company type