- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- full fill

Results for

Full fill - Import export

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

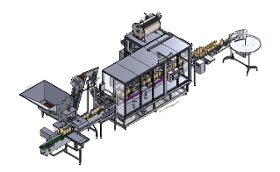

A full automatic packaging machine that fills in plastic containers and thermally welds them. It consists of five work stages that start with pulling the empty containers, then packing, then coverings, then welding and taking out. Suitable for medium products, with a production capacity of 1500 packages per hour.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

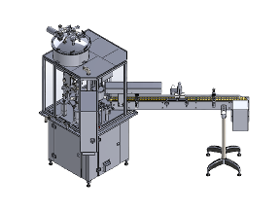

Full Automatic Machine For Filling and sealing and capping Tahini or any liquid or semi pasty products in plastic jars it’s seven working stage

Request for a quote

KULLEN-KOTI GMBH

Germany

Roller brushes Type 422 with sub-bodies e. g. tubular cores with journals are defined as having a body length longer than 100 mm (for brushes shorter than 100 mm, see "Circular brushes"). The brush cores (plastic or wooden cores with mechanically anchored bundle of fill material) either are mounted on steel shafts (WK1) or Steel /stainless steel tabular cores with journals (WK1 resp. WK4) for strength and rigidity. The comprehensive range of dimensions, core materials, fill materials and fill configurations demonstrates the versability of Kullen-Koti again and again. We would be pleased to supply you on request with details of special designs with wood or metal bodies. In case of brushes with non-cylindrical cores, we would like to ask you to send us a drawing or simply discuss your requirements with our technical consultant. Fill material densities: - High fill density EA1, - normal fill density EA2, - low fill density EA3. Fill configurations: In addition to a full fill...

Request for a quote

KULLEN-KOTI GMBH

Germany

Roller brushes Type 421 without a sub-body are defined as having a body length longer than 100 mm (for brushes shorter than 100 mm, see "Circular brushes"). The comprehensive range of dimensions, core materials, fill materials and fill configurations demonstrates the versability of Kullen-Koti again and again. But you should bear in mind that often a brush with a standard core diameter is more reasonable in price and can be supplied much quicker. The brush cores can be produced with plain bores for shaft mounting, as well as with keyways, dowel pin holes, internal or external threads and reducing bushes. In case of those special requests we would like to ask you to send us a drawing or simply discuss your requirements with our technical consultant. The max. circumferential speed for this brush type is 15 m/sec. Fill material densities: High fill density EA1, normal fill density EA2, low fill density EA3. Fill configurations: In addition to a full fill configuration in three...

Request for a quote

KULLEN-KOTI GMBH

Germany

Circular brushes are defined as brushes with a body length of up to 100 mm. The comprehensive range of dimensions, core materials, fill materials and fill configurations demonstrate the versability of Kullen-Koti again and again. As a matter of course it is more economical to use our standard dimensions for the brush cores. You will get your brushes in shorter time and for a lower price. Special models, for example with special fill configurations, core forms, axial hole with feather key groove, feather key dowel hole and collet thread or ball bearing are no problem for us. In case of special brushes, we would like to ask you to send us a drawing or simply discuss your requirements with our technical consultant. The max. circumferential speed for this brush type is 15 m/sec. Fill material densities High fill densty EA1, normal fill density EA2, low fill density EA3. Fill configuration In addition to a full fill configuration in three densities, we also produce circular brushes...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CL MACHINERY GMBH

Germany

Lowest Maintenance Cost 6,000 hours of maintenance-free operation (even in aggressive hot-fill bottling environments) Full stainless steel construction to prevent corrosion Lowest rebuild time / simple design NO lubrication required during 6,000 hour scheduled maintenance interval; unique hub configuration eliminates need for daily / periodic lubrication Less downtime for reduced cost High-Speed, Efficient, Consistent Application Industry-leading closure application speed: up to 50 bottles per minute / 3,000 bottles per hour per head Fully calibrated for static torque and head-rise indication; torque range: 8-34 inch lbs. Operational reliability: maintains calibrated settings in extreme conditions Proven, most consistent application torque performance over the widest range of operating spindle speeds Consistent removal torques for reduced consumer complaints Quick change design: torque adjustment, top load, and chucks Visual indicators Optimal magnet geometry Protected seal...

Results for

Full fill - Import exportNumber of results

7 ProductsCountries

Company type