- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- free line

Results for

Free line - Import export

MESUTRONIC GMBH

Germany

SPECIAL CONVEYING SYSTEMS TRANSTRON SERIES S / M / L / XL / CM / CL / CX CONVEYING OF PACKED PRODUCTS AND BULK MATERIALS IN THE PRODUCTION LINE WITH “METAL FREE AREA” FOR THE INTEGRATION OF METAL DETECTOR. High value tailored solutions. Reliable continuous operation. Guaranteed long-term, trouble-free metal detection results.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

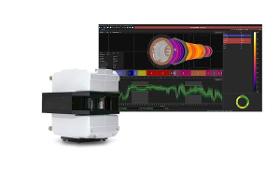

The CS400 Kiln Shell Imaging System relies on the MP Linescanner, which provides continuous, accurate and real-time thermal images and temperature measurements for moving processes. With the ability to scan up to 1024 data points in a single scan, the MP Linescanner can provide a complete picture of even the highest speed manufacturing processes, ensuring an accurate temperature reading. Key Features: — Polar charts highlighting coating thickness and brick thickness — Envelope profiles – including alarm functionality – over the entire kiln — Built-in, on-network storage to store historical data — Free scalable AOIs (areas, line and slice) including temperature trend analysis — Virtual 3D walkthroughs across the entire kiln — 3D views available per each defined kiln zone — Easy-to-use software configurations that showcase the scanner position relative to the kiln — Flexible image sizing and configurable orientations of rotation — Fail-safe “hot spot” alarm outputs

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWZ 5106 is a backlash-free metal bellows coupling in line shaft design. Because of the double cardanic system, the compensating of high shaft displacements are possible. The clamping hubs in split hub design can be mounted lateral at the aligned shaft extensions. Torsionally stiff and flexible line shafts are used in applications where torque and rotational motion combined with the highest possible angular precision should be transmitted or considerable distances between shafts need to be bridged. The application range of line shafts covers almost all technical areas, where mechanical power transmission and stiffness are important: Torsionally flexible line shafts with elastomeric spider Absolutely backlash-free Installation length up to 4 m possible Compensation of axial, radial and angular misalignment Cost-effective, simple assembly Maintenance free Variable length of the intermediate steel or aluminium tube Backlash-free elastomeric spider Excellent transmission of...

Request for a quote

INOEX GMBH

Germany

SAVEOMAT Satellite is the innovative vacuum conveying system in which the suction capacity can be split as required. The valve technology on the vacuum manifold allows the power to be split between different material separators. A control of the applied vacuum ensures a constant vacuum during material conveying and guarantees a delay-free material supply. Complete extrusion lines or entire production halls can thus be supplied via a single or several vacuum generators connected in parallel. The suction power is applied as needed for each individual component, ensuring careful feeding, even of critical materials. Other advantages/features: — Splitting of the suction power according to requirements — Simultaneous conveying of several material separators — Vacuum is available immediately — Careful material conveying — Reduction of energy costs — Suitable for PE, PP and PVC granules

Request for a quote

MOSCA GMBH

Germany

KKOV 315, Basic Model Laterally friction-weld sealing Height moveable, horizontal arch Sealing unit, moveable laterally to the package PLC control Operation via 7" touch panel 10 freely configurable programs with up to 10 strapping positions Can be integrated into most production lines Potential-free contacts to upstream and downstream machines KOB 315, Special Version Like basic model KOV 315; additionally equipped with 2-side aligning device KOH 315, Special Version Like basic model KOV 315; additionally equipped with 4-side aligning device Options: SoniXs Ultrasonic sealing system Vertical edge protection applicator Three-part signal light including low strap indication Air conditioning equipment Strap sealing unit BSG 4 Data interface KSR-2 DC sealing unit HL sealing unit with floating head Design with operator button in addition to touch panel Structural colour according to RAL-scale

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PLANET-AIR GMBH

Germany

The oil-free SILVER-LINE compressor OF-S90-25 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 25 liter air tank.

Request for a quote

PLANET-AIR GMBH

Germany

The oil-free SILVER-LINE compressor OF-S90-4 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 4 liter air tank.

Request for a quote

PLANET-AIR GMBH

Germany

The oil-free SILVER-LINE compressor OF-S90-15 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 15 liter air tank.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Since 1994, the 100% Venjakob affiliated company Nutro, USA has designed and installed turnkey robotic paint lines with robots from the most well- recognized and trusted robot suppliers such as ABB, Fanuc, Kuka, Motoman, and Staubli. Robotic paint lines provide the ultimate in precision and repeatability in painting performance. Due to the reduction in downtimes, training and personnel costs, a robotic paint system is ideally suited for paint application lines where uniform coating of complex 3-dimensional parts is needed. In addition to the solid construction, these robotic paint lines offer the safety needed for robots with the latest PLC and PC interfaces. This makes programming and operating simple and error-free for paint line personnel. Robot painters by Nutro are used for the following parts: Venjakob can provide your company with a complete new line or integrate a robot painter into an existing finishing line.

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac’s microMIRA™ LLO system provides highly uniform, force free lift off of different layers on wafers at high processing speed. The unique line beam system is built on a highly customizable platform that can incorporate different laser sources, wavelengths and beam paths to meet each customer’s unique requirements. The laser system can be used for a variety of applications, such as GaN lift off from glass and sapphire substrates in microLED display manufacturing as well as in semiconductor manufacturing. Additional applications include laser annealing and crystallization for surface modification. Force free and extremely fast line beam laser processing No damage due to thermo-mechanical effects Low production costs Elimination of costly and polluting wet chemical processes Integration of adjacent manufacturing steps for higher fab productivity

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The 520 DOTStar is a compact workshop unit for permanent, flexible markings on almost every material. This BORRIES product offers the best technology in a low-wear and low maintenance design for an unrivalled competitive price. The large marking area offers the opportunity to mark single or multi lines texts, in free scalable size. Angle and circular arc markings are also possible as well as date, time and consecutive numeration. The marking data can be entered easily via the included BORRIES marking software VisuWin SE. A graphical user interface enables a quick installing and adapting of marking pictures (layouts). Available marking technologies: dot-peening, vibropeening and DataMatrix Coding (ECC200).

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 320 is a compact marking unit for permanent and flexible markings on almost every material. This BORRIES product offers the best technology in a low-wear and low maintenance design for an unrivalled competitive price. The large marking area offers the opportunity to mark single or multi line texts, in free scalable size. Angle and circulate markings are also possible as well as date, time and consecutive numeration. The marking data can be entered easily via the included BORRIES marking software VisuWin SE. A graphical user interface enables a quick installing and adapting of marking pictures (layouts).

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The workshop unit 317 is a compact marker for permanent and flexible markings on almost all materials. Due to the ball bearing spindles and the carriage with circular ball track in both axes this model is very robust. The large marking area offers the opportunity to mark single or multi lines in free scalable dimensions. Angles and circular arcs, date, time and serial numbers are possible as well. Standard delivery is with LDM Macro software. Here, standard settings are printer or layout mode. Optionally VisuWin SE as well as VisuWin PRO PC software are available.

Request for a quoteResults for

Free line - Import exportNumber of results

14 ProductsCountries

Company type