- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flow form

Results for

Flow form - Import export

GURTEC GMBH

Germany

A flow formed roller shell and hollow formed shaft Option for an increased wall thickness at the middle of the shell for reduced shell deformation and increased fatigue life Extremely low TIR with a accurate and constant shell thickness significantly reduces vibration and increases service life Dimensions: Roller diameters 159 – 219 mm (6-1/4” to 8-5/8”) Shaft diameters up to 82 mm (3-1/4”) Bearings 6308, 6310, 6312

Request for a quote

GURTEC GMBH

Germany

GURTEC’s Heavy Mining Idler Roller is setting a new standard for high speed mass transportation and life cycle costs. Our highly automated manufacturing line utilises a flow forming process for extremely round tubes and an end forming process to round shell edges and integrate concentric bearing houses to the roller shell body, avoiding the need for welding.

Request for a quote

TRIBO-CHEMIE GMBH

Germany

Forging lubricant for aluminium and non-ferrous metal Temperature Range 160 °C to 400 °C Properties and Advantages • promotes the metal flow during forming process resulting in optimal form filling and accurate, precise parts • perfect release • much cleaner forgings, hardly any residues • reduced cleaning effort • high surface quality • improvement of tool die life due to adhesion of protective graphites • various modifications available e. g. Graphitex® CR 25-9/14

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

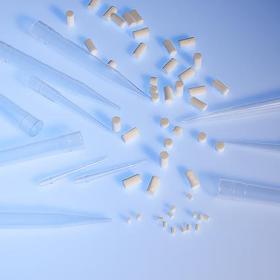

Greater protection from aerosols and aspirated liquids Our new FORTRESS™ Pipette Tip Filters offer a liquid-sealing barrier devoid of any contaminates or additives that can cause PCR, molecular, or analytical methodology and protocol issues. Specifically designed to protect the sample and the pipetter from harmful aerosols generated during the pipetting process or from liquid aspirated into pipette tips, our filters: Ensure purity –Non-leachable and extractable sample recovery is backed by the Certified Pure Porex™ program of independent analytical, clinical, and life science testing. Protect sample integrity–Seals out aerosols and liquid contaminates while preventing cross-contamination and sample carryover. Improve accuracy and precision–Design is optimized for maximum consistency in air flow, form, fit, and function across a broad spectrum of pipetting volumes.

Request for a quote

IBK WIESEHAHN GMBH

Germany

We supply IBK folding clamp couplings in brass, stainless steel, aluminium and PP. Our couplings have proved their worth under hard conditions in steel works and are regarded as standard. Material: - Couplings made of brass - Seals made of NBR (optionally of EPDM or Viton) - Clamp made of stainless steel Attribute: - Vacuum sealed for suction lines - No danger of icing - Interchangeable with systems of the same kind (MIL C-27450) - Suitable for closing male and female parts Temperature: - Working temperature from – 40°C to + 120°C, for higher temperature inquire suitable seal Pressure: - Max. 16 Bar working pressure –> Safety Factor 4 - Vacuum – 0,8 Bar Benefits of these couplings 1. perfect flow 2. No eddies form in the flow 3. the nozzles cannot fall out 4. the shells cannot slide about. 5. Precise fl ow control, impact-resistant, nonrusting 6. firm fit Special models on request! The dimensions stated are approximations. Subject to technical alterations

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS Classic is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its portal form it is particularly space-saving in depth and the increased tension force allows even high-density materials to be emptied without a problem. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

The use of protective gases is an essential element of precise quality control (HACCP) in food packages (Modified Atmosphere Packaging = MAP). MAP gas mixers by WITT provide controlled gas quality and safety in your packaging process – for germfree and preserving food. WITT offers gas mixing and metering systems for all packaging machines used in the food industry, no matter if vacuum packaging, thermo forming, flow pack or chamber packaging machine. The gas mixing systems are adjusted to your specific product type and processing and require only basic installation requirements. WITT system solutions are developed in close collaboration with national food and research institutes. WITT is approved and certified according to ISO 22000 for food safety.

Request for a quote

ILS INNOVATIVE LABOR SYSTEME GMBH

Germany

Seals with different materials for your specifically application: PTFE- seal -virginal- - high chemical resitance PTFE- black- seal -special PTFE- - high chemical resistance - less friction than virgin PTFE - less electrostatic charge - higher robustness - less "cold flow"* - higher longevity Ordering Information: For syringes with PTFE black- seal please add "bl" to catalog no. (xxxxxxx- bl) PE- HD- seal -Poly ethylene High Density- - better durability than virginals PTFE when working with salty solutions *what we by mean by "cold flow"? Virgin PTFE changes its form under pressure . GC Autosampler Dani ALS Agilent Technologies(HP) Siemens LC12/ 20/ 32 LEAP CTC Carlo Erba Finsons Shimadzu AOC14/ 17/ 20 Headspace Sampling Perkin Elmer Shimadzu AOC 5000 Mitsubishi DIA Instruments HPLC Autosampler Gynkotek Dionex Gina Agilent (HP) LaChrom Waters® Spark Kontron Perkin Elmer LEAP CTC Shimadzu Thermo Finnigan Thermo Seaparation Spectra- Physics Varian TLC CAMAG Linomat III, IV and V Robbins Hydra CTC Instruments HTS, HTC,LC- PAL Combi& GC- PAL Instrument Compatibility

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

The Flowform® screw is a polygonal screw based on TAPTITE 2000®, which makes use of the technology known as "flowhole-forming" in manufacturing processes. Using this technology the Flowform® screw causes the sheet metal to heat, using a combination of axial force and relatively high screwdriver speed . Once the material has been penetrated the polygonal shape of the screw forms a calibrated metric female thread which can accept a metric screw in the event that a repair is required. After the torque-controlled assembly process the formed through-hole adjusts optimally to the contours of the screw. This gives the following advantages: Higher process reliability in the screw fastening with the option of a larger screwdriver shut-off window More flexibility when selecting the screwdriver, and more straightforward monitoring of the assembly process. In addition the Flowform® screw considerably reduces screw-in times.

Request for a quoteResults for

Flow form - Import exportNumber of results

11 ProductsCountries

Company type