- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flexible machining centres

Results for

Flexible machining centres - Import export

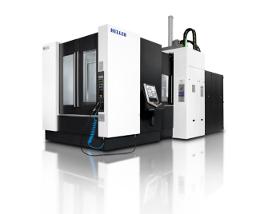

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

The perfect 4-axis machining centre must be capable of being configured to your requirements, produce reliably even under extreme loads and offer a fair price/performance ratio. Our solution: HELLER H-series 4-axis machining centres. Components that have been reliably used in mass production for years coupled with a high dynamic guarantee you robust processes – even at their limits, seven days a week in 3-shift operations.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Designed for Production: The new generation of 5-axis machining centres F sets a new benchmark for cutting performance and precision With its head kinematics, the new generation of the 5-axis F series has been designed from the ground up for flexible series production. Like all HELLER machines, they set a benchmark for cutting performance and precision. Other highlights include free chip fall, short idle times, optimum automation capability and compatibility with the H and FP series for a wide range of workpieces. In addition, the new models come with top-of-the-range specifications and the option to add technologies such as Mill-Turn, interpolation turning or power skiving.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 22 ensures the precise, cost effective and efficient production of parts. The numerous automation solutions enhance its range of application; individual configuration is easy thanks to the modular design. The Hermle engineers have essentially designed and created this machine with space in mind. With the most efficient footprint possible, the C 22 offers maximum efficiency. And it goes without saying that large components can be machined, too. Nonetheless, the C 22 is ultra compact and ensures the necessary clearance for 5-side/5-axis machining. Short process cycles, quick workflows and the highest possible machine dynamics: The C 22 is designed to machine complex geometries with high accuracy and small tolerances. The circular tool magazine is integrated into the base body of the machining centre and can house up to 65 cutters; additionally, it is possible – as with almost all HERMLE machining centres – to adjust the operating system to the user.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 52 is intended for the simultaneous 5-axis machining of workpieces weighing up to 2000 kg - with unbeatable accuracy and precision. Parameters that always represent a challenge for the machine dynamics. HERMLE has overcome these challenges by developing and designing a precise and high-performance machining centre. The C 52 is the successor of the extremely successful C 50. The C 52 machining centre: A flexible all-rounder with a large working area and minimum footprint. The tool magazine of the C 52 is also integrated and can be extended to 325 pockets using an additional magazine. The C 52 sets new standards: These standards are particularly valued in demanding applications, for instance in the medical, aerospace and automotive industries. In short: wherever the highest precision and maximum efficiency are required. Milling and turning in one clamping - the MT series with the model C 52 U MT dynamic.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Flexible machining centres - Import exportNumber of results

4 ProductsCompany type