- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fill level sensors

Results for

Fill level sensors - Import export

MINEBEA INTEC GMBH

Germany

The PR 6251 fill-level sensor is specially designed for basic weighing of silos and horizontal tanks. It meets all requirements for years of trouble-free operation without adjustment. For use in EX zones 1, 2, 20, 21, 22 and DIV 1. Ultra-flat load cell for low precision tank weighing as alternative to level sensors Load cell capacity range from 500 kg to 16 t Accuracy class: L (0.5 %) Corresponding mounting kit: PR 6051

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors react when a filling level is exceeded or falls below a limit. Aqueous mediums like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate. Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage. Types of Media The level monitoring sensors are designed for two different media types: For electrically conductive liquid media with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) For electrically non-conductive liquid media

Request for a quote

MICRO-EPSILON

Germany

Laser distance sensors optoNCDT ILR103x/LC1 are designed for fast displacement measurement between 0.2 and 15m or rather up to 50m with reflector. The fast response time of 10ms is typical for this series. With buttons at the quite small housing a Teach-In or the assignment of switching points can be done quickly. Tasks of this sensors are fill level measurement, positioning or length measurements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Continuous volumetric and pulsation-free dosing regardless of viscosity ▪ For low viscosity and self-levelling materials (e.g. trickle resins) ▪ Low wear solution due to avoidance of material contact at shaft seal ▪ Uninterrupted production thanks to material reservoir with up to 350 ml usable volume ▪ Pressure and temperature sensor including sensor holder at pump outlet ▪ Level programmable using analog level sensor ▪ Filling under atmospheric pressure ▪ Optional connection for process gas (max. 0.2 bar pressure) ▪ Dispenser holder for easy and stable installation ▪ Increased process reliability due to integrated safety device ▪ Dividable rotor assembly for easy & fast replacement and low spare part costs

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

Robust and reliable level monitoring for fluids and bulk materials in cylindrical design with thread. The sensors are suited for installation using mounting plates and nuts or adapters in the tank wall. The sensors are based on the proven capacitive principle. The medium to be detected functions as dielectric. The medium in touch with the sensor generates a capacity change. This is converted into a switching signal or an analogue 4...20 mA output signal. EGE filling level sensors in cylindrical design are designed for rough industrial environments with PTFE housing for use in aggressive media. Also available with robust stainless steel thread.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE amplifiers process the signals of the EGE filling level sensors for extreme temperatures at a safe distance and are used to set up the sensor via intuitive operation using potentiometer and LED strip. Amplifiers for EGE high temperature limit switches feature an auto-calibration of the switching point at the press of a button. EGE amplifiers provide switching signals or analogue signals, dependent on the device.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

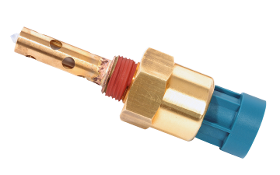

Areas of Application and Advantages BEDIA CLS 10 stands for special versions of our well-proven CLS 40 series for heavy duty applications. Currently, the BEDIA CLS 10 series includes a variety of sensors, which are compatible replacement parts for level switches from Cooper Standard and Robert Shaw which are obsolete nowadays – and this in well proven BEDIA quality. This also includes sensors with 2 complementary CMOS outputs. It should be emphasized that the water sensors with two complementary outputs can be operated with a supply voltage of 4.75 V DC – 32 V DC. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate (at a frequency of approx. 600 kHz). Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quoteResults for

Fill level sensors - Import exportNumber of results

10 ProductsCountries

Company type