- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feed tanks

Results for

Feed tanks - Import export

ELKON GMBH

Germany

In some countries, cement is widely delivered by railway. The cement carried in wagons can be transferred to the cement silos with special pneumatic cement feeding system developed by ELKON. ELKON Cement Delivery System from Railway consists of wagon feeding hopper, intermediary feeding screw, material holding tank, pressure tank, compressor and control panel. The system which has a cement feeding capacity of 50 tons / hour can also be used to feed a large number of cement silos.

Request for a quote

ELKON GMBH

Germany

Cement material supplied with big bags or bags can be transferred into cement silos by means of ELKON Big Bag/Bag Pneumatic Cement Feeding System. ELKON Big Bag/Bag Pneumatic Cement Feeding System consists of cement feeding hopper, intermediary feeding screw, pressure tank, compressor, loading crane and control panel. This feeding system, which has a capacity of 15 tons/hour, is equipped with 2 tons crane to lift the big bags and dispatch into the feeding hopper. The complete set of ELKON Big Bag/Bag Pneumatic Cement Feeding System fits into 1 unit 40’OT container and thus it can be easily transported to overseas countries.

Request for a quote

A.B.S. SILO- UND FÖRDERANLAGEN GMBH

Germany

Flexible indoor silo made of breathable, uncoated polyester fabric for a constant feed quality without the formation of mould and lumps. The lowest-cost storage possibility with an optimal space utilisation.

Request for a quote

A.B.S. SILO- UND FÖRDERANLAGEN GMBH

Germany

Flexible indoor silo made of breathable, uncoated polyester fabric for a constant feed quality without the formation of mould and lumps. The lowest-cost storage possibility with an optimal space utilisation.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Water treatment for steam boiler systems — Prevention of corrosion in the boiler — Outstanding deaeration efficiency and reduced consumption of chemicals with WSM-V complete deaeration system — Partial deaeration module WSM-T for small systems — Fast and easy planning, installation and acceptance appropriate to the steam boiler in question — Requirement for positive suction head allows for ground-level installation and easy commissioning

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

Our steam generators are available on request as a ready-to-operate steam boiler plant: CERTUSS steam generator plus CERTUSS supply unit CVE. All components for the water supply and water conditioning of the CERTUSS steam generator are included in the complete steam plant. - Feed water tank - Desalination heat exchanger - Water softening equipment - Test extraction cooler - Mixing heat exchanger - Measuring equipment - Steam dryer The CVE supply unit is compatible with all the CERTUSS steam generators. In addition to the CERTUSS supply unit as a ready-to-operate boiler house installation on a basic frame, we also offer a complete container installation on request. Depending on the desired steam output a multiple steam boiler plant may be suitable for you.

Request for a quote

DINO ANLAGE- UND MASCHINENBAU E.K.

Germany

Fully equipped steam boiler with feed water tank

DINO ANLAGE- UND MASCHINENBAU E.K.

Germany

We supply units up to 750kg/h! Complete with feed water tank, pumps and controls

WHITE STEEL GMBH

Germany

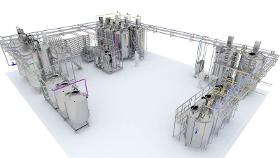

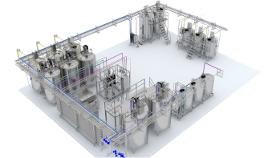

SPECIFICATION Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple product viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

1,Specification •,Milk Double jackets cooling collecting tanks •,Chillers. •,Storage feeding tank •,Processing section •,Cheese press to mold machines •,Mozzarella cheese making machines •,Vacuum cooker cream cheese making machines •,Rotary bottles washing system •,Milk, yogurt and cheese filling, sealing and capping machines •,Fermentation room. •,Compact design •,Available certification up on your request UL, CE, GMP, FDA, ASME. •,Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. 2,Description ,High stability on high capacity. ,Can handle multiple ointment viscosity and types ,Type of metal used S.S 316 / 304 ,Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Boiler feed water The so called „Boiler feed water“ is stored in a feed water tank and continuously feeded to the boiler of a steam generator. A big quantity of feed water is needed for example in steam power plants. The boiler generates steam, which is used for heating, for chemical processes or for driving a steam turbine respectively a steam engine. The feed water is purified in a way, that all harmfull components for the boiler are removed or neutralized. Leakages and evaporation loss are compensated by additional water which is purified in the same way than boiler feed water. Very often, valuable well and potable water resources are used for the generation of process water. Environmental regulations restrict this usage of well and potable water continuously and increase the costs for this resources steadily. The conditioning of stream water to boiler feed water helps saving potable water and means cost advantages. The process of conditioning is based on ultra filtration with down

Request for a quote

PERO AG

Germany

After production of repair, the workpieces are lowered in a parts carrier into the immersion tank. A pump feeds cold cleaning agent containing solvents into the tank so that dirt is dissolved and removed by flooding. Persistent dirt can be removed manually with the flowthrough brush. The cleaning medium in the tank is constantly recirculated through a filter. Cleaning with sprayable cold cleaning agents containing hydrocarbons with a flash point > 60 °C Manual cleaning station Continuous filtration of cleaning medium Immersion tank suitable for wide range of workpieces Available as 1bath unit with loading of the unit via Manual loading

Request for a quoteResults for

Feed tanks - Import exportNumber of results

14 ProductsCountries

Company type