- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extrusion

Results for

Extrusion - Import export

W. MÜLLER GMBH

Germany

Space-saving in a vertical (e.g. for retrofitting) but also in a horizontal version, our extruders are available in many variations for your specific needs. For applications with larger throughputs, we have high-quality extruders with heat-separated feed zone cooling, which deliver a high-quality melt for the further process. We also offer coordinated screw designs for special materials such as PVC, PA, EVOH, E-PET or adhesive layers.

Request for a quote

ROLF KÖRNER GMBH

Germany

Filter belts are used for a continuous filtration of polymer melt. These filter belts, but also wire mesh pre-cut parts, are manufactured in various dimensions and weaves. For high demands the fabrics are available with high tenacity warp wires. Plasma cut edges assure a continuous and frictionless passage of the filter belts Materials:Stainless steel, plain steel, combinations of various materials.

Request for a quote

ROLF KÖRNER GMBH

Germany

We produce filter discs and cuttings in any measurement and shape from wire cloths and metal fiber felts. All products can be ultrasonically cleaned, if requested!

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

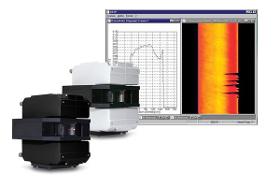

Thermal imaging system based on the Raytek MP150 infrared linescanner. Detailed web temperature profile based on 40,000 measurement points per second Automated temperature monitoring Automated quality monitoring for ISO9000 Ensures proper web temperatures for strong film-to-substrate adhesion Enables plant operators to reduce scrap and improve profitability and product quality Quick and automatic detection of “wavy” or “running” edges, gaps, and torn edges Define product-specific configurations (recipes) Automatically analyze “automatic sector” temperature distributions Visualisation on PC Playback stored files as “movie” Multiple language support Integrated OPC server for remote system control Ethernet TCP/IP interface integrated in the line scanning system PC-independent alarm output Analog outputs 3 x 4 – 20mA Analog or digital output modules For sheet extrusion see the Raytek ES150 system.

Request for a quote

LEONI DRAHT GMBH

Germany

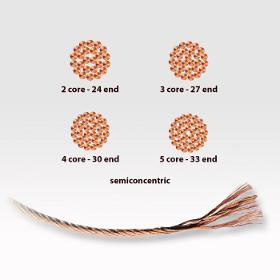

Strands with a semi-concentric structure made from Cu-ETP1, Cu-OF1 and LEONI Histral® alloys in bare, tin-plated, nickel-plated or silver-plated, soft annealed. Single-wire diameter ranging from Ø 0.05 mm to Ø 0.51 mm, left-hand lay or right-hand lay. Cross-section ranging from 0.03 mm² to 16 mm². The individual wires are subject to an exact positioning, yet without an additional core wire, which ensures an all-out uniform structure. Concentric strands are particularly appropriate for thin-gauge coating with high-grade isolation materials (extrusions). The technical qualities of a semi-concentric strand can be extremely well and accurately customized by combining several different alloy wires.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our custom blow molded parts such as containers, air conduction tubes, connection tubes and drainage tubes are 3D blow molded, suction blow molded and manipulated by a robot (3-D Roboter Blow Moulding Machine). They are 100 percent leak-proof and guarantee consistent wall thickness. Since the blow molds are developed by and tailored to customer specific requirements, a perfect fit is guaranteed, the number of assembly steps is reduced, weight is reduced and the risk of leakage is minimized. Available materials / maximum operating temperature: PE / -40°C up to + 70°C PP / -40°C up to +105°C Dimensions: max: 900x500x300mm min: 50x20x100mm eight/pc.: 10-3.000 Gramm diameter: min. 8-10 mm Application: Industrial applications, such as home appliances, air conditioning, medical technology, etc.

Request for a quote

GOLDEN COMPOUND GMBH

Germany

GC green 2012-91 MI T15 contains 20% natural fibers and is a biomaterial - allrounder for various extrusion applications. With GC green you get a resource-saving and home-compostable material with ground sunflower seed hulls. The fibers from sunflower seed hulls are a by-product of sunflower oil production. They are GMO-free, do not compete with food and do not require additional acreage. Often this material has already been used for various biodegradable labels. In order to provide you with an optimal color selection, we have had 10 masterbatch colors certified by TÜV Austria. We will be happy to advise you. Further advantages of GC green: 100% recyclable Reduced cycle times No sink marks Lower energy input In addition to our allrounder compounds, we naturally have many other material formulations. Just contact us, together we will find the perfect compound for your application.

Request for a quote

HEXPOL TPE GMBH

Germany

In the extrusion process the TPE pellets are poured into a hopper are heated in the barrel and turned into a melt by this heat and shear. A screw carries the melted plastic through a shaped die to produce continuous lengths of shapes with the same profile, which are then cooled by air or water. Our TPE compounds are easily extruded into single and complex profiles. They can also be co-extruded with other materials to yield a part with both rigid and soft components. They exhibit improved profile flexibility. The SEBS compounds, with their saturated intermediate blocks, are very stable against thermal degradation. On the other hand, the SBS compounds degrade if overheated or if a screw with excessively high compression ratio is used. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information SEBS based materials Equipment Extruders used for polyolefines are best for TPE comp

Request for a quote

W. MÜLLER GMBH

Germany

Our extrusion heads for blow molding meet the highest demands in terms of precision, availability, performance and ease of use. And They ensure your safe and cost-efficient production.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

There are many benefits of impact extrusion. Whether combined, forward or backward extrusion, there is a high level of dimensional accuracy and the possibility to achieve a close approximation to the final shape. Offering 100 percent tightness, impact aluminum extrusion allows a high degree of transformation in a single production step, high operating speeds at low unit costs and numerous shaping and design possibilities. In addition, impact extrusion provides compact structure, a smooth surface, no soldered or welded seams and excellent stability.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump specially designed for use in the production of medical tubing made of TPE, PE or PA. The melt pump is installed downstream of the extruder in the extrusion process for pressure build-up and constant delivery of the melt to the die. It is particularly important for medical tubing that the wall thickness and quality is absolutely constant and uniform.

Request for a quote

W. MÜLLER GMBH

Germany

The perfect combination of head and complete extrusion is the heart of every blow molding machine - tailor-made for your product and adaptable to every machine. Our platforms guarantee the greatest possible security and user-friendliness for users.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The ES Thermal Imaging System for Sheet Extrusion from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized applications and industrial environments. The ES Thermal Imaging System is ideal for continuous web applications such as hot strip mills, continuous casting, glass wool production, laminating for both glass and plastics and more. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field

Request for a quote

W. MÜLLER GMBH

Germany

The extremely space-saving design of our screen changer allows a lot of creative freedom, both with new machines and in the case of retrofitting, since the structure of the extruder platform only needs to be adjusted a little. The screen changer is installed instead of a connection piece and can be equipped with a hydraulic or electric drive. The simplest way, however, is to use a cordless screwdriver, which makes changing bits a quick and easy endeavor. Screen changers are available for all common throughputs.

Request for a quote

MICRO-EPSILON

Germany

The LVP-25-Z20 and LDR-14-Z20 sensors are used for monitoring the clamping position in machine tools. These inductive sensors are integrated in the release device and directly measure the clamping stroke of the drawbar onto which the target ring is glued. Due to their extremely compact design, these sensors are used for different types of tools while providing high-precision and continuous monitoring. No adjustment is necessary when changing the tool.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

We supply tailored, special parts manufactured with our state-of-the-art cold-moulding and extrusion equipment. We can press cold-moulded articles – whether solid, semi-hollow or hollow – according to your drawings. Complex moulded parts and individual, special projects are our strengths. Our cold-moulding competence covers flanged bolts, studded parts, stepped bores and parts with an internal or external thread. Possible materials: Regular steel, stainless steel, brass, copper, light metals. Available with all standard surfaces.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

– Volumetric printing system – Disposable caps with rotor and piston – For low to high viscosity biomaterials – Linear relation between dosing volume and rotation speed – Active suck-back prevents dripping or stringing of biomaterials – Precise start and end points – Low-maintenance and durable print heads – Easy integration into bioprinting machines – Driven by a 2-phase stepper motor – Luer-Lock connection for dispensing needles

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALUMINIUMWERK UNNA AG

Germany

Aluminiumwerk Unna AG one of the world’s leading manufacturers of aluminium alloy tube. We produce a variety of specialist aluminium alloy products. Our core focus is the production of aluminium alloy tube and tubular profiles. These can be offered as seamless extruded or porthole extruded products. The extruded products can also be cold drawn making it possible to offer a comprehensive range of final dimensions.

Request for a quote

ALUMINIUMWERK UNNA AG

Germany

Aluminiumwerk Unna AG is specialised in the production of Aluminium tubes. The Aluminium tubes are extruded on site using two possible methods. These are either Seamless extrusion or Porthole extrusion. It is quite simple to distinguish between the two extrusion methods. In seamless extrusion, a mandrel is positioned and fixed inside the extrusion die, creating the inner contour of the tube. In porthole extrusion, the mandrel is fixed and is supported by a number of integral bridges affixed to the outer portion of the extrusion die.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for the production of medical flow. Melt pumps of this type are used, among other things, in the production of medical fluids, such as those used in respiratory masks. The melt-blown fluid can be used in many different ways in protective masks or filters. The EXTRU series is exkat adapted to the requirements of the melt-blow process and thus works with highest precision.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

EXTRU - Melt pump for extrusion and pressure increase of medium to high viscosity media. The extrusion gear pump is mainly used in combination with extruders or kneaders. It reduces the natural pulsation of the extruder and compensates for fluctuations in delivery, especially in single screw extruders. The extrusion pump is used as a melt pump. It builds up the required feed pressure, which is needed for the downstream die. The pressure build-up in the gear pump can be much more efficient than in the extruder itself. The extruder is relieved by using an extrusion pump. Furthermore, considerably less energy or heat is introduced into the polymer. The melt pump thus contributes to conveying the product as gently as possible. The EXTRU is indispensable for the production of precise films or micro pellets.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for the production of HDPE / LDPE / LLDPE. Melt pumps of this type are used in the production and processing of HDPE / LDPE / LLDPE. The EXTRU series is exkat adapted to the requirements in these processes and thus works with highest precision. Special serrations allow an almost pulsation-free conveyance of the melt, which guarantees a constantly high product quality.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The Gneuss Processing Unit (GPU) is a modular configuration of different Gneuss products and technologies, which are combined in to a high performance extrusion line for the manufacturing of high quality products.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The MRS-EXTRUDER from Gneuss is a multi rotation system that can be used for applications such as bottle to bottle recycling, thermoforming sheet, and PA degassing. Its compact, and robust layout utilizes multiple small extruder barrel integrated with "satellite"screws that rotates at the opposite direction as it enhances the surface exchange of the polymer melt.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The basic version of the ZwickRoell Mflow extrusion plastometers can be used to establish the melt mass flow rate (MFR). The plastometer’s modular design is expandable using the piston transducer to permit determination of the melt volume flow rate (MVR) as well as for automatic adaptive parameter configuration. Common uses occur in goods inwards checks and quality assurance. Mflow extrusion plastometer includes the Zwick's automatic adaptive parameter configuration, which sets test parameters based on the material being tested to automatically minimize measuring errors. The basic version of the Mflow extrusion plastometer is designed to perform MFR tests in accordance with Method A and can be expanded for MVR tests as per Method B. Tests to the following standards are possible: Methods A and B as per ISO 1133, ASTM D1238, ASTM D3364, JIS K 7210.

Request for a quote

TRAS MM

Germany

Email : trasmme@gmail.com SKYPE : TRAS MM ============================== ALUMINUM SCRAPS We can supply you with High quality 99.7% min Aluminum scraps of various types . We will offer you different types of scraps like rod, plate, wire, cable, wheel, shredded, clipping, heavies, die cast, girder, can, tank, mix materials, etc. Please below we offer most grades of Aluminum Scraps such as: Aluminum alloy wheel scrap Aluminum wire scrap Aluminum Extrusion 6063 scrap Aluminum engine block scrap Specification 1.Competitive price 2.Fast Delivery Within 20 days 3.SGS , BV 4.Professional factory

Request for a quote

HEXPOL TPE GMBH

Germany

Due to their efficient processing, high performance and recyclability, Dryflex TPE compounds have proved themselves as a quality replacement for vulcanised rubber in window and door sealing applications. Colour and co-extrusion have further enhanced the design possibilities. We develop custom formulated materials which deal with the design, performance and environmental needs of the future. Dryflex TPEs are totally recyclable and can be reprocessed and regenerated to produce functional gasket products. We have developed trade standard grades, including compounds developed to meet the requirements of BS 7412:2002 Class A or B standard and are suitable for ‘static’ (Class A) or ‘dynamic’ (Class B) applications. As well as grades that meet the requirements of RAL GZ 716/1, Class IV (and Class V) standard. Our Dryflex Extrusion range also includes translucent, foamable, rigid and semi-rigid compounds. Download the Dryflex Extrusion Profiles Product Guide

Request for a quote

ALFRED SCHÜTZE APPARATEBAU GMBH

Germany

SCHÜTZE extrusion valve MVV The mini extrusion valves of series MVV are designed for the application of oils, release agents and other thin liquids. The application can be done punctiform or linear. nozzle + needle: stainless steel available nozzle dimensions: 0,2/0,3/0,4/0,5/0,6/0,8 mm Ø

Request for a quoteResults for

Extrusion - Import exportNumber of results

40 ProductsCountries

Company type

Category

- Extrusion, plastics - machinery (7)

- Electric motors and parts (4)

- Gear pumps (4)

- Extrusion of rubber and plastic (3)

- Aluminium alloys (2)

- Filtering equipment and supplies (2)

- Gears (2)

- Infrared tubes (2)

- Measurement - Equipment & Instruments (2)

- Extrusion - steel and metals (1)

- Aluminium and aluminium alloys (1)

- Hoses, pipes and tubes - plastic (1)

- Pipes and tubes, aluminium (1)

- 3D printers (1)

- Design, graphic and plastic arts - products and supplies (1)

- Oilseed crops (1)

- SMALL METAL PARTS (1)

- Sensors (1)

- Studs and bolts, fastening (1)

- Testing of products and materials (1)