- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extreme products

Results for

Extreme products - Import export

GRÜNING & LOSKE GMBH

Germany

E-glass is the basic material for isoGLAS®. Texturing guarantees a large storage volume and thus good insulation properties. isoGLAS® products are extremely textile and harmless to health. Available dimension: 3 - 30 mm.

Request for a quote

GRÜNING & LOSKE GMBH

Germany

E-glass is the basic material for isoGLAS®. Texturing guarantees a large storage volume and thus good insulation properties. isoGLAS® products are extremely textile and harmless to health. Available dimension: 3 - 30 mm.

Request for a quote

GRÜNING & LOSKE GMBH

Germany

E-glass is the basic material for isoGLAS®. Texturing guarantees a large storage volume and thus good insulation properties. isoGLAS® products are extremely textile and harmless to health. Available dimension: width: 8 - 120 mm, thickness: 0,2 - 10 mm.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Fusion™ 6HF – s200 is a heat treatable product for applications with extremely demanding formability requirements. This product is recommended for inner applications such as decklid and door inners and other closure inner panels. This product has an excellent balance of properties for forming and strength. In addition, it offers a unique advantage in the hemming process enabling sharp feature lines and rope hem designs that permit the reduction in perceived gap between adjacent panels. All values are typical.

Request for a quote

ORBIS EUROPE

Germany

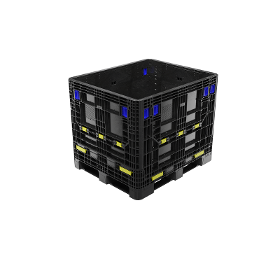

ORBIS reusable bulk containers are designed to protect and transport heavy parts in automotive and industrial applications. Engineered for rugged applications, the plastic bulk containers are extremely robust and offer comprehensive product protection over a long service life. The 1200 x 1000 plastic bulk containers are available in multiple heights for increased packing density. The collapsible design with a return ratio of up to 1 : 3 reduces the shipping of air during return transport to a minimum. Key features: - manufactured from recycled material - multiple heights, access door and bottom configurations - durable all-plastic design - improved workplace safety - easy, on-site repair and part replacement - 100% recyclable

Request for a quote

TROTEC GMBH

Germany

Because the units carry the label made in Germany you can be sure that you are buying a top-quality, highly efficient and extremely reliable heating unit which will carry on heating in the most hostile of environments and harshest of conditions. Theres also an electronically-controlled multistage switch to regulate air flow and air temperature so that you can carry out blasting, coating and painting work in fact almost any surface work at all - at a constant temperature both indoors and out. Here the low-down on the TEH 300: Heating performance: 80 kW Air flow rate: 6000 m³/h Mains voltage: 400 V Power: 123 A Power socket: CEE 125 A plug Mobility: wheelable/ fork lift / crane Sound level (distance 3 m): 76 dB (A) Air pressure: 600 Pa Temperature increase ΔT: 60 °C Length: 1.625 mm Width: 800 mm Height: 1.245 mm Weight: 245 kg Some of the TEH 300s abundant qualities: Extremely robust top-quality product "made in Germany" Stackable

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Fusion™ 6HF – e200 is a heat treatable product for applications with extremely demanding formability requirements. This product is recommended for outer applications such as body sides and decklid outers. This product has an excellent balance of properties for forming and strength. In addition, it offers a unique advantage in the hemming process enabling sharp feature lines and rope hem designs that permit the reduction in perceived gap between adjacent panels. All values are typical.

Request for a quote

INFICON GMBH

Germany

Advanced, Affordable Rate Control for Single or Multiple Layers Now get everything you want in a thin film deposition controller for single and multiple-layer processes. The XTC/3 with patented ModeLock provides proven mode hop prevention for consistent quality. With the XTC/3 Thin Film Deposition Controller, you get highly accurate control of deposition rate and thickness, the capacity for virtually any number of layers, easy installation, and extremely high reliability to ensure productivity. INFICON, the global leader in thin film deposition control, now offers an instrument with a remarkably low cost of ownership for unprecedented value. Whether your control needs reflect production or research and development use, you will find a precise match in the INFICON XTC/3. Worldwide INFICON Support No matter where you are, you get fast answers, attentive service, and maximum uptime. With offices around the world, INFICON is the only manufacturer of thin film deposition...

Request for a quote

GRÜNING & LOSKE GMBH

Germany

E-glass is the basic material for isoGLAS®. Texturing guarantees a large storage volume and thus good insulation properties. isoGLAS® products are extremely textile and harmless to health. Available dimension: width: 8 - 120 mm, thickness: 0,2 - 10 mm. Special version: one side self-adhesive.

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Typical applications: Furnace, boiler and chimney doors, expansion joints, cable sheathing. E-glass is the basic material for isoGLAS®. Texturing guarantees a large storage volume and thus good insulation properties. isoGLAS® products are extremely textile and harmless to health. Available dimension: 3 - 30 mm.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The model 8527 high-precision compression load cell is the ideal load cell for reference measurement chains where highly precise measurement results are required. Its very high production quality and extremely low non-linearity of just 0.035 % F.S. make it a dependable choice for comparative measurements and calibration tasks. Designed for a dynamic stress of up to 100 % of the full scale value, the model 8527 load cell is also suitable for situations where a rapid signal change with high amplitude occurs and has to be measured. The model 8527 high-precision compression load cell has a domed load button on top, onto which the compressive load being measured is applied. Inside the load cell is an elastic membrane, on which strain gages generate a resistance change in the measuring bridge and an output signal proportional to the load. For the best possible measurement results, the force should be applied axially and centrically to the load button.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The products to be recorded can be fed on multiple tracks into a LED camera system, which individually measures and then weighs them at a weighing station. Based on the captured data, the highest yield and minimal give-away is guaranteed during slicing of pieces/chunks and slices. Advantages Open design, simple handling High fault tolerance Excellent detection of products with extremely fluctuating color contrasts Precise measurement even in extraneous light The laser scanner is available in various sizes to fit your product.

Request for a quote

MINEBEA INTEC GMBH

Germany

The freefall metal detection system Vistus® RS is an electromagnetic sensor which reliably detects even the minutest metallic partials during production flow. Its extremely compact design allows for easy integration into your existing production line. Safe detection of metallic foreign objects with the highest detection sensitivity Exceptionally space saving Simple installation and operation Reduces defective product quality and customer complaints Robust and long-lasting design

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – Utilises internally developed mixers in the process systems. The incorporation of process data enables precise reconciliation before and during the mixing process. In conjunction with the in-line process, this results in extremely gentle treatment of the products and a high degree of efficiency. Continuous production of fruit yoghurt, cream quark, fruit quark and herb quark, as well as thermally processed cheese Precision and low losses with type changes Compact layout and configuration of the system in line with customer wishes Bacteriologically compliant (hygienic) design of system parts – optionally available in sterile versions Your added value through miromatic mixing systems: Dosing accuracy +/- 0.5% Low fruit and product losses when changing containers Precision and low losses with type changes Extremely gentle product treatment (with low rotational speeds, no shear effect) Individual design of the mixing system to suit your process

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Mixing technology is particularly wide-ranging in the food and drinks industry. From simple suspension and homogenization tasks in storage or transport containers, right through to complex reduction tasks, during which mixtures can be exposed to only the lowest of shear forces – you will find it all in the food and beverages industry. High food sensitivity and the multitude of fields of application for agitators require close process coordination with the customer, in order to design, construct, and finish the agitators in the optimal manner with the widest variety of mixing elements. In addition to its popular standard mixers, Geppert also has special stirring elements within its portfolio, capable of being extremely gentle on the product while remaining highly efficient. All agitators have the relevant food approvals and can also be supplied with clean room drives and special sealing systems.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory model supplements the well-established Lödige mixing granulator range. The laboratory mixing granulator permits the same process steps as the production machines: — Mixing — Moistening — Granulation — Temperature control (using double jacket) The laboratory mixing granulator is delivered operation-ready with a CE conformity declaration. For the sizes, please refer to the machine flyer. A three-bladed impeller rotates at the bottom of the vertical, cylindrical mixing vessel, to create a vortex type of circulation for the material to be mixed. Very short mixing times and excellent mixing quality are achieved, even if the product components are extremely different. The separately driven chopper (only for the 5, 10 and 15 l vessel) is designed for breaking up of agglomerated material, for uniform moistening, wet granulation and streak-free mixing of dyes, as required.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Different types of films and cushion types can be produced on our low-cost AirBoy nano3. Therefore you have the best flexibility for your transport protection, even with low throughput.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 paper bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Different film types can be processed on our efficient AirBoy nano4, giving you the best flexibility for your goods dispatch even with low throughput. AirBoy nano4 Fastest small machine on the market 4 speed modes 4 / 6 / 8 / 10 m per min No heat-up phase - air cushions can be produced immediately Easy exchange of transport belts Production of extremely tight air cushions possible without compressor Ideal for small packing stations for air cushion production on demand Start/stop at the touch of a button Variable timer for air cushion production Variable sealing temperature, air volume Compatible with narrow air cushion chains Compatible with wide air cushion mats Supplied with instructions, power cord, 2 spare PTFE bands and spare blade Content of the nano4 paper bio starter set: AirBoy nano4 air cushion machine 1 roll air cushion chain | Type 9.7.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK is your specialist in the production of cold-rolled profiles tailored to individual customer requirements. With a wide range of different technologies, we manufacture special profiles as customized functional elements up to complete assemblies. SCHOCK's roll forming technology operates economically and material-efficiently, offering significant advantages in product design: Unlimited range of shapes Highly precise functional dimensions Economical material utilization Energy-efficient manufacturing process SCHOCK special profiles are characterized by the highest precision and top-notch workmanship. With SCHOCK's roll forming technology, we produce profiles with extremely tight tolerances and excellent product properties. Thanks to creative tool solutions, we manufacture virtually burr-free profiles and process different materials with a tensile strength of up to 1000 MPa.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

To view and download the brochure please click on the left image. This egglayer / block making machine is solid and productive. The COMPACT is suitable for the production of block elements up to a height off 330 mm. The stable, torsion-proof frame and the solid processing also enabel production under extreme climatic conditions. Control system Reliable control unit (Picture: semi-automatic version) for the precise control of the motion. Programming is possible according to desires of the client without programming unit. Inductive limit switches Contactless, space saving and wear resistant limit switches guarantee a secure and precise switching function. Control panel The control panel is easy to operate and was specially designed for the environment of concrete plants. Hydraulic Reliable, state of the art HAWE-hydraulic unit (picture: semi-automatic version). Security standrad High security standards in regards to working reliability and accident prevention. Frequency...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The SMC presses from Siempelkamp are designed in such a way that they can also be used for the RTM process. Short cycle times Since the SMC process is predominantly used in the production of high quantities, apart from precision, a short cycle time plays a important role. And since the compound material is chemically reactive, the time window for achieving an optimum surface quality is also small. The advantages of the Siempelkamp presses: they apply the force extremely quickly to the product, because they close at a very high speed decelerating just before reaching the end position. Depending on the level of automation, the tool change is done automatically – just 120 seconds later the next part can be produced! No stress The precise positioning of the ram plate ensures that the tools are precisely aligned to each other during the complete press stroke – not just on the last millimeters. Under all operating conditions the tools remain parallel.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -LC 200: jaw width 200 mm, width of vice base 164 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force - Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -For automation of machining centres – particularly suitable for batch production -The hydraulic spindle also enables the use of support jaws with which a wide range of unmachined parts, from flame-cut and sawn materials through to complex castings, can be clamped securely and economically. Suitable for materials with a strength of up to approx. 1000 N/mm². Product features: -Extreme accuracy for your machining -The clamping force is generated via the pressure from a hydraulic unit with a hydraulic clamping stroke of up to 4.5 mm -The clamping force is steplessly adjusted by regulating the hydraulic pressure on the hydraulic unit. A hand crank is provided for coarse adjustment of the clamping range -The spindle contains a single-acting hydraulic piston and an additional Belleville spring assembly

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -Lateral installation is also possible Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 6 increments. At most, 1 revolutions are required to reach the max. clamping force -For clamping two identical parts (dimensional differences of up to ± 3 mm are compensated for) -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -Workpieces must be placed in both stations before clamping begins. -Type 90: drive head with finer clamping force presetting for delicate workpieces (6 increments)

Request for a quoteResults for

Extreme products - Import exportNumber of results

46 ProductsCountries

Company type

Category

- Machine tools - metal machining (13)

- Furnishings, cushioned (5)

- Labelling machines (4)

- Packing and packaging - machinery and equipment (2)

- Cars - electrical and electronic parts and components (2)

- Boxes, plastic (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Food Industry - Machines & Equipment (1)

- Heating, domestic - installations and equipment (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical engineering - custom work (1)

- Mechanical transmission systems and components (1)

- Metal detectors (1)

- Metal industrial presses (1)

- Mixers and grinders for the food processing industry (1)

- Plastics - machines and material for industry (1)

- Rails and sliding frames (1)

- Sensors (1)