- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ethernet ip

Results for

Ethernet ip - Import export

HANS TURCK GMBH & CO. KG

Germany

The programmable gateways of the BL20 (IP20) and BL67 (IP67) I/O systems can be used as autonomous PLCs for control tasks or as network devices for fast signal preprocessing in the periphery. For this, the gateways have a fieldbus interface for PROFINET, Modbus TCP, Ethernet/IP™ or PROFIBUS-DP; in addition the gateways support standard Ethernet and serial communication. The extension modules communicate via the internal module bus with the gateway and can be configured independently of the fieldbus protocol.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

Our modular fieldbus and remote I/O-systems offer a comprehensive range of solutions for factory and process automation with interfaces for the fieldbus protocols PROFIBUS-DP, DeviceNet™, CANopen, Modbus TCP, Ethernet/IP™ and PROFINET. excom® is a remote-I/O-system in IP20 for Ex and non-Ex areas. You can plan and implement tailor-made solutions for the I/O IP20 area with the universal BL20 bus terminal system. The modular IP67 fieldbus systems BL67 and piconet® can be mounted directly in the field.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

The BL ident® interfaces are obtainable as a set together with the gateway and one to four RFID modules in IP20 or IP67. Also available are interfaces for connection to PROFIBUS-DP, EtherNet/IP™, Modbus TCP, DeviceNet™, PROFINET, CANopen und EtherCAT®. A maximum of 16 parallel operating channels are possible. Programmable gateways enable distributed and fast signal processing. Alternatively, the BL compact series offers customized interfaces in the form of compact, fully potted IP67 components.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

The TBEN-PLC is a robust and compact IP67 control for cabinet-free automation concepts. With the modern CODESYS 3 programming environment object-oriented programming in the following IEC 61131 languages is possible:Instruction List, Ladder Diagram, Function Block Diagram, Sequential Function Chart and Structured Text. In addition to the 8 universal digital I/O channels the PLC supports various Ethernet and fieldbus protocols as master and slave. These include PROFINET, EtherNet/IP™, Modbus TCP, CANopen, SAE J1939 and Modbus RTU.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

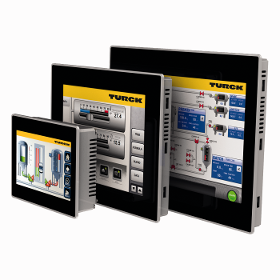

The HMI controls of the TX500 product series have high-quality displays with brilliant graphics, resistive touch, and a modern processor. They are ideal for use in small to medium-sized machines, whose processes must be controlled, operated, and observed locally. The CODESYS 3 control of the TX500 has the functions PROFINET controller, EtherNet/IP™ and Modbus TCP as well as Modbus RTU Master. When used with Modbus protocols, the HMIs can also be operated as slaves. For visualization the CODESYS 3 target is used.

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

For factory automation we offer compact fieldbus I/O-modules for PROFIBUS-DP, DeviceNet™, CANopen, INTERBUS, AS-interface®, Modbus TCP, Ethernet/IP™ and PROFINET. The IP67-modules for use in harsh environments have glass-fiber reinforced plastic housings and metal-connectors, are fully potted, vibration and shock-proof. The IP20-modules for DIN rails can not only be installed in control cabinets, they can also be used to integrate small, decentralized control boxes with a few I/O-signals to a fieldbus network.

Request for a quote

MICRO-EPSILON

Germany

The Industrial Performance Unit is a powerful computing platform for the efficient commissioning of Micro-Epsilon 3D sensors. The fully compatible controller is ideally suited to inline processes in 3D measurement tasks. The intuitive 3DInspect software with Valid3D technology enables simple and fast sensor parameter setting, which allows measurements to start immediately. The Industrial Performance Unit directly processes three-dimensional data, which is subsequently evaluated and assessed via the 3DInspect software. Results can be output via the integrated PROFINET, EtherCAT and EtherNet/IP interfaces.

Request for a quote

MICRO-EPSILON

Germany

The interface and signal processing units extend the field of application of Micro-Epsilon sensors. The interface modules are used to convert sensor signals into digital or bus-compatible interfaces. This enables interfaces such as USB, RS422, Ethernet/IP, Profinet and EtherCAT for numerous sensors. The signal processing units are also used to record several sensor signals, to calculate and output them together. This is necessary, for example, for planarity measurement or thickness measurement.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

The probe's measurement data can be sent to a PLC via Ethernet, EtherNet/IP, PROFINET or EtherCAT fieldbus Fieldbus compatible interface module: MG80-NE (Ethernet) / MG80-EI (EtherNet/IP) / MG80-PN (PROFINET) / MG80-EC (EtherCAT) Up to 16 MG80-CM counter modules for measuring probes can be connected to each main module. Up to 64 MG80-CM or touch probes can be connected to MG80-NE via max. 3 LINK connections Up to 255 MG80-CM or measuring probes can be connected to MG80-EI/PN via LINK connections. Theoretically, up to 65,535 MG80-CM or mestasters can be connected to MG80-EC via LINK connections. MG80-CM Counter module for connection of one DK or DT series probe (with MT13) Easy installation on DIN mounting rail LZ80-K1/K2 I/O module for MG80-EI, MG80-PN and MG80-EC Equipped with 8 inputs and 8 outputs

Request for a quote

MINEBEA INTEC GMBH

Germany

With Dypipe we guarantee you a new level of safety and flexibility in your production process of viscous and liquid products. The system can be equipped with various separators, connections, and mounting options that offer unmatched flexibility, making it the perfect solution for your production line. An innovative sample insertion system ensures specimen validation in live operation. For the high hygienic requirements in meat applications the Dypipe comes with an easy-open separator, specifically designed for this purpose. The X-ray inspection system is made of stainless steel and has a protection class of either IP 65 or IP 69. Several interfaces such as OPC UA, Ethernet IP and the Minebea Intec software for statistical process and pre-packaging control SPC@Enterprise pave the way to increased productivity.

Request for a quote

MINEBEA INTEC GMBH

Germany

The freely programmable process controller, designed for applications as diverse as simple weighing complex manual and automatic Batching and single component Filling. Extensive connectivity options and compatibility with all analogue load cells and the digital Pendeo® load cells as well as platform scales and many more weighing solutions. Connection of one analogue or one digital scale or Pendeo® digital load cell system 4.3" large colour display with multilingual interface and integrated help function for intuitive operation Multiple interface possibilities: Ethernet TCP/IP, Modbus TCP, Profibus DP, DeviceNet, Profinet, Ethernet/IP and USB Equipped with an internal web server, the Maxxis 4 can be configured and controlled via any standard web browser Automatic backup function saving data to SD cards for full transparency and traceability

Request for a quote

MINEBEA INTEC GMBH

Germany

As the first weight transmitter for analogue strain gauge load cells, the Link E has a high-contrast touch display that makes it easy to read and easy to find all settings and information. Configuration takes place via your favourite web browser – no additional software required. ‘Smart Calibration’ enables adjustment entirely without the need for weights. This keeps installation and access times to a minimum. The Link E gives you the option to choose from nine widely-used interfaces for any application, including ModBus-TCP, Profibus, ProfiNet, DeviceNet or Ethernet/IP. The Link E is the result of the continued development of the successful PR 5211.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Control room application mPilot is a control room application for Mahlo equipment. The software allows the user to configure up to ten Mahlo devices with one control centre. Individually selected data of several devices are clearly arranged. The innovative control tool supports production and shift managers in handling their daily business as efficiently as possible. Key elements Display of running processes of up to ten Mahlo machines Job control (configure jobs and recipes) Configuration of product lines and machines Alarm management (current and historical warnings) Various communication protocols (OPC UA, OPC DA, Modbus TCP, Profibus, Profinet, Ethernet/IP) Start of predefined jobs (only with mCockpit)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Single color, two color and fiber optic models Temperature range: 50 to 3200 °C (122 to 5792 °F) Superior optical resolution to 300:1 Spot sizes down to 0.6mm (0.02 inch) Fast response times down to 2 ms Easy adjustment with manual variable focus integrated head optics Through-the-lens sighting, with optional laser, LED or video aiming function Compact, rugged housings with IP65 (NEMA-4) rating Ethernet, Profinet and EtherNet/IP options Programmable relay output for control Simultaneous analog and digital outputsThe Fluke Process Instruments Endurance® series has been designed to meet the requirements of modern industry that allows you to integrate with all major control systems quickly, easily and seamlessly. The series are available in single color, two color and fiber optic Endurance models. The innovative Endurance® Series of low-temperature and high-temperature two color pyrometers meets all requirements of modern industry: it is flexible and easy-to-install; durable to withstand

Request for a quote

MINEBEA INTEC GMBH

Germany

OPC UA (Open Platform Communications Unified Architecture) is a standard for communication in the field of industrial automation - more precisely: a machine-to-machine communication protocol for industrial automation. The server enables cross-operating system data exchange between, for example, scales and higher-level systems such as ERP or MES systems. miOPC is suitable, for example, for the Combics, Signum, Midrics and IS platforms. With miOPC, Minebea Intec, as an innovation leader, offers a new solution for the market that takes an important step towards standardisation and customer independence. Your benefits: — Simple connection of existing scales via Ethernet TCP/IP or serial RS232 — Standard OPC UA scale profile according to the OPC Foundation: "OPC UA Compendium Specification for Weighing — Data security through encryption — Simple, intuitive operation

Request for a quote

BÜHNEN GMBH & CO. KG

Germany

Experience new options for integration of the HB 6000 Connect into an existing peripheral. Via Modbus, Profibus, Profinet and Ethernet-IP, you have full control over the connection to your existing parent machine. The touchscreen creates an innovative connection between the operator and the system. All system information that is relevant for the bonding is clearly and graphically displayed – at a glance. The temperature control is easily operated via the touchscreen. Highest compatibility The HB 6000 Connect is compatible with various manufacturer brands. Heated hoses and application heads from Nordson and Robatech can be connected and used with Plug & Play. Thanks to the integrated control, a granulate feeder1 or a level control1 can be easily connected and configured. The power of the device is shown in the melting and conveying/flow capacity. Melt up to 30 kg of hot melt adhesive per hour2 and even convey up to 66 kg per hour2 via the piston pump.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

• Real-time thermal imaging, scan speed up to 300 Hz • Up to 1024 measurement points per line • Wide choice of spectral and temperature ranges • High-quality brushless motor (MTBF 40,000 h) • Built-in Ethernet TCP/IP communications • PC independent alarm output • PC independent 4-20 mA interfaces (3 outputs) • I/O module support for up to 10 sectors/zones (PC independent) • Internal Line Laser for accurate alignment • Rugged, waterproof IP65 enclosure • Air purge keeps window free of dirt and condensation • Built-in water cooling for ambient up to 180 °C (356 °F)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Thermal imaging system based on the Raytek MP150 infrared linescanner Automatic temperature and quality monitoring in continuous web processes Detect thermal problems early Faster product changes and reduced setup time Communicate with process control system via OPC Reduce scrap APPLICATIONS Plastics, metals, paper, and building industries, combustion prevention, hotspot detection, flat and float glass production, automotive, food processing and numerous other industrial applications FEATURES Onboard Ethernet TCP/IP communication Product specific configurations or “recipes” Custom measurement sectors Optional analog and digital outputs for each sector Analog outputs 3 x 4 – 20mA PC-independent alarm output Visualisation on PC Software supports English, German, French, Finnish, Dutch and Italian languages

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Kiln shell temperatures are monitored along the entire length of the kiln. The infrared line-scanning system detects kiln hot spots due to refractory loss, damage, or wear. Data from up to 4 scanners or individual point sensors (optionally used to monitor the burning zone and tire slips) can be seamlessly integrated into one complete thermal image. Detect abnormal operating conditions such as faulty flame position and shape! Optimize and manage kiln maintenance! Extend the operational life of kiln and refractory! Automated kiln and refractory monitoring Visualisation on PC Ethernet TCP/IP interface PC-independent alarm output Analog outputs 3 x 4 – 20mA To ensure reliable operation in even the harshest kiln environments, the MP150 linescanner, which is used in the CS210 thermal imaging system system, is designed with a rugged cast aluminum housing and mounted in a robust stainless-steel enclosure.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Raytek GS150 thermal imaging systems enable automated quality control in glass bending, forming, annealing, and tempering processes. The GS150LE variant is especially designed for Low-E (low emissivity) glass / one-side coated flat glass. It features automatic emissivity correction. The systems are based on the Raytek MP150 infrared line scanner, which has a max. resolution of 1024 points per line, a max. 150 Hz scanning frequency, and an up to 90° wide field of view. SYSTEM PROPERTIES • Automated temperature monitoring • Visualization on PC • Ethernet TCP/IP interface integrated in the line scanning system • PC-independent alarm output • PC-independent analog outputs 3 x 4 – 20mA BENEFITS • Improve profitability and product quality • Reduce set-up time • Detect defects quickly • Automate quality monitoring for ISO9000 • Reduce scrap • Efficiently manage the heat balance in the oven • Automatically adjust the emissivity value when changing glass types or coatings

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Raytek MP150 infrared linescanner is designed for temperature monitoring in demanding industrial environments. It generates accurate thermal images of moving objects, scanning up to 90° wide fields of view with a motorized mirror at up to 1024 points per line and at a max. 150 Hz frequency. An internal high-speed microprocessor calculates the temperature of the individual measurement points. — Real-time thermal line-scanner system for continuous or discrete process measurements — Optical resolution up to 200:1 — Built-in line laser for rapid alignment — On-board Ethernet TCP/IP communication — Wide choice of models and spectral responses The Raytek MP150 includes provision for air or water-cooling, three configurable analog outputs, and two-way digital communications. It can be used in standalone mode, connected to a single PC or integrated into a process control system using the Windows-based DataTemp DP software for remote configuration and real-time process monitoring.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The KRP model series rotary encoders are intended for connecting directly to the Ethernet/IP network. Setting the address, baud rate or terminating resistances is not necessary. The IP address is assigned via a BOOTP or DHCP server in the Ethernet/IP network.The integrated 2-fold switch enables the KRP model series rotary encoders to be used in star, tree and line network topologies.

Request for a quoteResults for

Ethernet ip - Import exportNumber of results

23 ProductsCountries

Company type

Category

- Measurement - Equipment & Instruments (5)

- Weighing and dosing equipment (2)

- Sensors (2)

- Connected objects (1)

- Infrared tubes (1)

- Measurement and regulation equipment and instruments - temperature (1)

- Potentiometers (1)

- Precision measuring instruments (1)

- Production and operational inspection (1)

- Software (1)

- Software for industry (1)