- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electronic scales

Results for

Electronic scales - Import export

MAGNESCALE EUROPE GMBH

Germany

PL81 / PL82 read heads for SL110 / SL130 tape scales with interpolation electronics and TTL output signal PL81: TTL through open collector output PL82: A/B phase via TTL line driver interface (RS422) Max. Response speed: 5m/s Max. Resolution: 10µm (phase to phase) Easy installation and large mounting tolerances For universal measured value acquisition e.g. in automation For connection to SPS counter cards Protection class: IP67 available Resistant to oil, dirt, vibration and shock

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 22 offers flexible expansion options, supports complex control tasks and MES/ERP connections, and enables remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line with container conveying, capping and labelling. Suitable for foaming, gassing or statically charging liquids, such as cleaning agents, it offers electronic scales, automatic container transport and drip-free under-level filling. Product is fed directly from storage tanks via gravity or pumps. ■ Almost foam-free, calibratable under-level filling ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ the ideal solution for small and medium-sized filling orders ■ simple operation ■ low space requirement ■ can be used immediately just connect energy (electricity and/or compressed air only) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers, such canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibrated above level filling of several containers on one pallet ■ thread-cutting, non-dripping filling valve ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

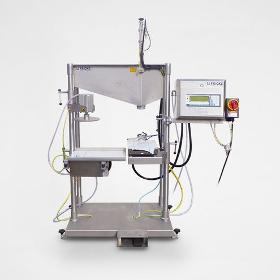

Filling station with electronic balance for precise filling of foaming liquids, for gassing products or products that load themselves statically, e.g.: cleaning and care products, solvents, chemical liquids, mineral oils, glazes. For the filling of open containers, e.g. canisters. Below level filling, coarse/precision filling valve, does not drip. Product supply via pump or gravity. The filling station has the following advantages: ■ a nearly foam free filling that can be calibrated ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ easy operation ■ the filling station needs only little space

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 42 enables complex control tasks and MES/ERP connections as well as remote maintenance. Its modular design allows it to be expanded into a fully automatic filling line with container conveying, capping and labelling. Suitable for viscous to pasty liquids such as paints, it features an electronic scale and fills open containers just above the filling level. The product is fed from storage tanks by gravity or pumps. ■ a calibratable over-level filling unit with travelling valve just above the filling level ■ Thread-cutting, non-drip filling valve ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ The ideal solution for small and medium-sized filling orders ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect energy (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers (min. Ø 150mm opening) just above fill level, e.g. canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above tevel filling just above the fill level with a ride-on valve of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for precise filling of non-foaming liquids, e. g. chemical liquids or mineral oils. For the filling of open containers, e.g. canisters. Below bunghole filling, coarse/precision filling valve, cut threads, does not drip. Product supply via pump or gravity. Direct connection via product hoses to the valve. The filling station has the following advantages: ■ a nearly foam free filling that can be calibrated ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ easy operation ■ the filling station needs only little space

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic platform weigher for precise filling of low viscous liquids, e.g.: paints, varnishes, dispersions. For the filling of standard container types, e.g. open cans, buckets and canisters. Above level filling for coarse and fine flow. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the Container (Container and valve can be cleaned in approx. 5 minutes by using 1 litre solvent) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or inks. For filling open containers, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. The System offers you: ■ calibratable above level filling ■ Thread-cutting, non-dripping filling valve ■ fast cleaning of the container (container and valve are cleaned in approx. 5 min using 1 l of solvent) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 10 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fully automatic filling system with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. detergents/cleaning and car products, solvents, chemical liquids, mineral oils, glazes. For filling open bunghole containers, e.g. canisters. Below level filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via gravity or with the help of pumps. Direct connection via product hoses to the valve. The system offers you: ■ an almost foam-free, calibratable below level filling ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the ideal solution for small and medium filling orders ■ simple operation by one person ■ Modular design enables extension by many automatic systems

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for filling liquids which froth, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. The machine offers you: ■ an almost froth-free, calibratable below Level filling ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 6 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 12 enables complex control tasks, MES/ERP connections and remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line at any time, including automatic container conveying, capping and labelling. It is suitable for viscous to pasty liquids such as paints and varnishes and offers automatic container transport options as well as an electronic scale. The station supports coarse/fine over-level filling and can be connected directly to storage tanks via inclines or pumps. The system offers you: ■ a calibratable oversize filling system ■ quick cleaning of the valve (the area in contact with the product consists of 3 parts) ■ quick changeover to other container dimensions and changing products ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of non-frothing liquids e.g. chemical liquids or oils. For the filling of open bunghole containers, such as canisters, bunghole drums or IBCs (Intermediate Bulk Container), directly on the pallet. Below bunghole filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ an almost froth-free, calibratable below bunghole filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fast filling of multiple containers on a single pallet. Filling station with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. For the filling of bunghole containers, e.g. canisters, bunghole drums or IBCs directly on the pallet. Below level filling, coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ an almost foam-free, calibratable below level filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Bags Forming Section – Rollers carried the bags roll driven by servo motor. – Sealed process done by a special mechanism according to the required dimensions controlled by sensors. Filling and sealing Section – Multihead weigher provides regular continuous flow during the filling process equipped with electronic scales connected to the control panel to achieve the required packing quantity. – Pouch Seal mechanism by thermal heaters and a knife, welldesigned, long life. – Conveyor to transfer bags out of the machine. Technical specifications – The pouch dimensions can be adjusted by sensors and a printed sign on the roll. – Its form and fills various types of bags.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Electronic scales - Import exportNumber of results

17 ProductsCountries

Company type