- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electromagnetic compatibility

Results for

Electromagnetic compatibility - Import export

IGUS® GMBH

Germany

Initiator cables, also referred to as sensor/actuator cables, connect control units and different sensors, or, in the case of reversal of the measurement principle, actuators. Frequently used abbreviations include ini or ini cable (plural: inis). Sensor or measurement transducers transform physical quantities such as rotation, speed, distance or length into analogue electric impulses. In the case of an actuator, the measured electric current (symbol: I, unit: ampere; A) or voltage (symbol: U, unit: volt; V) is transformed into temperature, pressure or torque. The connection cable consists of at least three cores with a small cross-section of between 0.14mm² and 0.34mm². In the simplest case, two cores are required for supplying the voltage, while the last core transmits an I/O signal. For sensitive applications, there are shielded versions in addition to the traditional ini cables to avoid EMC disruptions (electromagnetic compatibility).

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

The electromagnetically compatible design of a system, from first sketches through creating the circuit diagrams all the way to EMC-optimised routing on the circuit boards, allows the creation of a robust electrical product that will still function reliably even under difficult conditions. As specialists in ignition systems, we know the sources of electromagnetic disturbance and are world leaders in EMC processes.

Request for a quote

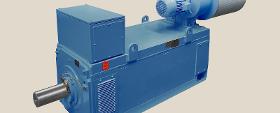

LLOYD DYNAMOWERKE GMBH

Germany

Our compact asynchronous motors are distinguished by high torques in combination with a small size. They are highly dynamic with a low inertial moment, with a proven design as well as electromagnetically compatible for optimal, compact performance levels. We develop our compact asynchronous motors specially as speed-controlled drivers and for a supply from frequency converters. They also consist of a flexible platform system and can be adapted to specific customer requirements. The housing is angular and jacketless. Being ventilated by a separately driven fan, the motors can constantly deliver the full torque over the entire speed range. The optimised control behaviour with converter operation means that these machines can replace DC machines.

Request for a quote

EWM AG

Germany

— Degaussing of pipes and metal sheets — Automatic degaussing before welding — Dependable degaussing for better welding results through stable welding process without magnetic deflection, minimisation of finishing work — activgauss (10–250 A) – degaussing during welding: — Avoids moving up of magnetic field during the welding process in case of very long and strongly magnetised components — Portable and robust — Quick connection at the pipe by means of three load cables — Use at -25 °C to +40 °C with mains voltage tolerances of +/- 20% Advantages of degaussing: — No deflection of the arc by residual magnetism in the workpiece — Prevention of lack of fusion due to insufficient sidewall fusion — Minimisation of finishing work — Cost-efficient and high-quality results — Set: Degauss 600 degaussing machine, two 5-metre, 35 mm² load cables, one 20-metre, 35 mm² load cable, RT DGS1 remote control and 5-m connection cable

Request for a quote

WESTMARK GMBH

Germany

• from high quality plastics • for all common spirits • for 0,7 - 1,0l bottles • not anise-resistant • Note: measure pourers only function flawlessly with unsweetened spirits

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KURT MAIER MOTOR-PRESS GMBH

Germany

General Characteristics of the brakes: 98/37/EEC Machine Instructions Regulation 73/23/EEC Low Voltage Regulation 93/68/EEC Electromagnetic Compatibility Regulation 60335-1-CEI Safety of electric devices for domestic use Regulation Regulation VDE 0580 Certificate UL/CSA File E210965 - EE219203 Certification ISO 9001:2010 95/16/CE: TÜV Institute Atex Ex Group II class 1 GD d T6 IIC in phase of certification nearby TUV SÜD 0123 New Machine Instructions 2006-42

Request for a quoteResults for

Electromagnetic compatibility - Import exportNumber of results

7 ProductsCountries

Company type