- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electric generators

Results for

Electric generators - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

Since the invention of the “Schniewindt grid” in 1902, we produce high voltage resistors and are thus among the pioneers in the electrical industry. Due to continuous development of our products and new developments according to the respective needs of the market, we are now one of the leading manufacturers of electric heating equipment, resistance equipment and sensors for current and voltage measurement

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Used in Paper Factory

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Motor as drive for a compressor for support of oil production.Special cooler design to withstand even sandstorms in the desert.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Hoist motors in various designs

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Motors for hoist, boom hoist, travel and trolley for ship to shore cranes.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Hoist motors in various designs.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Generator for power generation in a hydro power plant with pelton turbine.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Generators for power generation in a hydro power plant with Kaplan turbine.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Generators for power generation in a cavern power plant with pelton turbines.Runaway speed 1,800 rpm

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Utilization of the stored geothermal heat for generating electrical power.Suitable for safe operation in ATEX Zone 2 and earthquake area UBC Zone 4.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Synchronous generators from LDW are highly versatile and are used in shipbuilding, power stations and many other applications. Our generators can be driven by gas, steam or water turbines as well as diesel engines and other drivers. Synchronous generators from LDW have a high degree of efficiency and operate with extreme effectiveness. We develop and manufacture generators of the highest quality standards.LDW supplies synchronous generators with an output range from 4,000 to 60,000 kVA.Our synchronous generators are specially optimised for the specific application of the customer, e.g. if used for water power turbines with regard to runaway speed and turbine force absorption. Where diesel generator sets are used, the vibration load in particular is taken into account. On request, we will also construct the generator with a forged-on flange. A high degree of efficiency is ensured for all generators.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

With the new EMX model range of electric steam boilers, CERTUSS offers you twice the steam output as before with a significantly smaller footprint. Electric steam generators from CERTUSS are heated by stainless steel heating rods with a large heating surface. The output of the heating elements is regulated continuously via semiconductor contactors. One energy-efficient advantage is the immediate modulating output adjustment to the actual steam demand during the operating cycle. For greater steam demand of up to 640 kg/h or fluctuating steam loads, several ELECTRO steam generators can be cascaded in series. Multiple systems like this are an especially economical solution. Our compact electric steam systems feature built-in feed water tanks and feed water pumps. They require very little space and have a short heat-up time. Steam systems are also available as a unit with water conditioning equipment installed at the factory.

Request for a quote

TEPROSA GMBH

Germany

TEPROSA GmbH has specialized for many years in the manufacture of sophisticated, precisely fitting laminated cores of exceptionally high quality. In the field of electrical steel sheet, we manufacture individual laminations and sheets for stators and rotors, as well as entire sheet packages stator- or rotor packages) from various steel grades. We process grain oriented electrical steel for generators, transformers and other electrical machinery. Our most common method for packaging the individual laminations is baked enamel technology. Alternatives are welding or bolting of laminations. As a long-standing supplier to various OEMs, the quality of our work is particularly important to us. Therefore, we work according to uniform processes and thus ensure consistent quality and complete traceability of each individual production step.

Request for a quote

TROTEC GMBH

Germany

CERAMIC FAN HEATER TDS 10 MQuick, effective and draught-free warmth without burning dust The small ceramic fan heater is not only the ideal heating solution for allergy-sufferers to be used in living and work spaces. For, generally speaking, electric heaters are excellently suited for use in closed interior spaces, as they neither consume oxygen nor produce any combustion gases. The ceramic fan heater TDS 10 M still outweighs this commonly known advantage of electric heaters, for it is equipped with a PTC ceramic heating element instead of heating wires. Advantages of PTC as compared to heating wires: longer lifetime, less sensitive technology, shorter heat-up times, process-related overheating protection – and no burning of dust during heating, which additionally makes this ceramic heater suitable for allergy sufferers.

Request for a quote

EMBRO GMBH

Germany

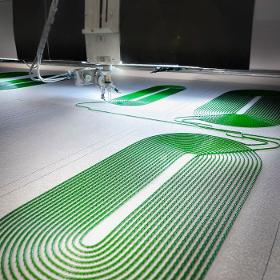

Where are magnetic field mats used? The coils currently manufactured by us are processed by our customers into so-called electromagnetic field mats. These mats are used in Pulsed Electromagnetic Field (PEMF) therapy. Many PEMF devices are suitable for private use at home. However, various health service providers including physical therapists as well as non-medical practitioners offer therapies based on magnetic fields. Why is our embroidery technology used for production? This technique creates circular-shaped structures that form the basis for a homogeneous flow/direction of the electric current. At the same time, the mechanical wire laying has an extremely high level of accuracy. The distances can also precisely be determined. How is the magnetic field created? Simply put, this is how electromagnetic fields are created: pulsating magnetic fields are generated by the electric current flowing through the wire. The more wire, the stronger the magnetic field.

Request for a quote

OPSYTEC DR. GRÖBEL GMBH

Germany

The irradiation chamber BS-02CT is a chamber to test samples according IEC 60335-1: “Household and similar electrical appliances – Safety – Part 1: General requirements - Edition 5.2” This test is designed for non-metallic materials that are exposed to direct or reflected UVC radiation from 200 nm to 280 nm. The test can be used to test radiation stability against UVC radiation that can cause aging like discolorations, changes in material properties, crack formation and smell. Therefore the UVC low pressure mercury lamps emit a continuous spectral irradiance of 10 W/m² at 254 nm. IR heater heat up the samples so that a black-panel temperature of 63 °C ± 3 °C can be reached and controlled. The time can be set to an exposure duration of 1000 h. The irradiation chamber BS-02CT can also be used to test material properties that are disinfected by UV-C. Typically the UVC dose of a daily disinfection for a period of two years can be accelerated to 12 hours.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

When operating with green energy, the boiler allows your company to achieve a CO2-neutral steam supply. — Generate up to 7.5 t/h steam in a highly efficient way using just electricity – no combustion, no emissions — High steam quality, excellent dynamics, full flexibility — Reduced expenditure: No flue gas, no fuel supply — Application-specific design and particularly reliable operation — Smart boiler control and seamless system integration — System equipment and service from a single source

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KELVION HOLDING GMBH

Germany

This new addition to our product line is a compact heat exchanger made from high-alloyed stainless steel and can handle temperatures up to 550°C. Its compact and modular design makes it extremely versatile and easy to service. Our exhaust gas heat exchanger is designed to recover heat from exhaust gas produced for example by combustion engines used in combined heat and power plants. The heat exchanger transfers the heat from the exhaust gas to a liquid (water or water-glycol solutions). When heated up, this liquid can be used in central heating systems; for preheating air in the combustion chambers of furnaces and turbines; to dry coal, pulp, wood and other materials as well as for generating electricity with a Rankine process.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The electrical steam generators E 100 M – 120 M from CERTUSS offer you impressive output in two output capacities of 100 - 120 kW heat output. They are compact, economical and have a high output. All electrical versions do not require a permit for installation and use in Germany. Heating: Electrical heating rods Steam output 135 – 160 kg/h The sizes: E 100 and E 120 - In two output capacities of 100 - 120 kW heat output. - Fully electronic pressure and output control. - Compact stainless steel heating rod with low heating surface load, placed laterally on the pressure body for easy access. - Constant network load without consumption peaks. - Integrated multifunction display. - Multilanguage plain text indication.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The electrical steam generators E 6 M - E 72 M from CERTUSS offer you impressive output in 14 different output sizes. They are compact, economical and have a high output. All electrical versions do not require a permit for installation and use in Germany. Heating: Electrical heating rods Steam output 8 - 97 kg/h The compact: E 6 M – E 72 M - In 14 different output sizes. - Easy-to-service compact device – easy to operate. - Direct access to all parts from the front for easy maintenance. - Fully electronic pressure and output control, immediate load adjustment. - Function and malfunction indications can be linked to central control system / building services control system provided by - customer. - Low space requirement, reduced and robust heavy-duty model in elegant design. - Fully automatic operation by means of time control or remote pulse (optional). - Automatic clarification and desalination (optional).

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fully automatic filling system with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. detergents/cleaning and car products, solvents, chemical liquids, mineral oils, glazes. For filling open bunghole containers, e.g. canisters. Below level filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via gravity or with the help of pumps. Direct connection via product hoses to the valve. The system offers you: ■ an almost foam-free, calibratable below level filling ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the ideal solution for small and medium filling orders ■ simple operation by one person ■ Modular design enables extension by many automatic systems

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for filling liquids which froth, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. The machine offers you: ■ an almost froth-free, calibratable below Level filling ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 6 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fast filling of multiple containers on a single pallet. Filling station with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. For the filling of bunghole containers, e.g. canisters, bunghole drums or IBCs directly on the pallet. Below level filling, coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ an almost foam-free, calibratable below level filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

KERSTEN ELEKTROSTATIK GMBH

Germany

The discharging generator DG 306 is the power pack of the KERSTEN next product family and can be used to supply all the next® discharging components. With its 6 high voltage connections he can easily manage every large installations, nevertheless it is very compact. With the patented DC High voltage technology you don´t have to worry about EMC interferences anymore while you receive the best possible discharge power. By using the 24 V DC fault indication contact, you have the option to receive a fault signal directly in your system. the High voltage Generator DG 306 is supplied by a 24 v DC input voltage and is therefore independent of the world´s different network standards. The generator provides two insulated and against reverse polarity secured high voltage connections, where discharging devices can be fast and easily connected to.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

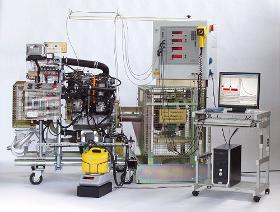

Particularly for testing passenger car engines, truck engines and transmission units with combustion engines, when - the electric mains is too weak for frequency converters, - cooling water is not available or water-cooling is not desired, - air-cooled eddy-current brakes are not sufficient.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

Our engine test beds are modular systems existing of control unit, dynamometer and mobile engine supports. Applications: Determination of engine performance, runnning engines under a defined load in order to determine other measuring values. Fields of application: Science, development, quality control by manufacturers and control authorities, education (especially air cooled dynamometers). New: Container for outdoor installation for performance testing at combustion engines with all kinds of dynamometers. Our range of engine test beds: - with eddy-current brakes (air-cooled or water-cooled) - low-inertia hydrostatic braking dynamometers - braking dynamometers with water brake - regenerative 4-Q-dynamometers - electric generators, loaded by resistors

Request for a quote

STRONG MAGNETS GMBH

Germany

Arc magnet is one of the basic shapes of Neodymium magnet, also called segment magnet, they are widely used for electric motors, PM motors and generators in the electrical engineering and electric vehicles etc. Arc magnet can be made with high Hcj materials to match special motor applications, it can be consistency for torque performance and ground to meet high precision and concentric requirements.

Request for a quote

ANDRITZ KAISER GMBH

Germany

The production of electric motor and generator laminations imposes strict requirements on the press and automation. ANDRITZ Kaiser looks back on decades of experience in the electric motor laminations sector and provides the customer with state-of-the-art solutions. Precise timing and general performance are required for competitive productivity of high speed stamping systems for laminations. Due to the large amount of cutting operations required, a very rigid machine is needed to absorb the cutting impact without damaging any machine part. Finally, the tolerances of 0,02mm in the tools and the end product call for a very precise slide movement, slide guideance and low frame deformation. Our well designed and thoroughly tested concept allows customers to manufacture high-quality products with maximum efficiency. ANDRITZ Kaiser production lines for electric motor laminations are characterized by the following features: Highly stable machine with split-design, cast iron frame for...

Request for a quote

COMPUR MONITORS GMBH & CO. KG

Germany

Fixed gas detection system for oxygen, toxic and combustible gases This DIN – rail mounted modern control module saves space, money and installation time. One safe controller for all gases: Any combination of a sensor head plus control module is a complete gas detection system. This makes the Statox 501 so safe and reliable. The Statox 501 also gives you the opportunity to alter or expand existing systems with minimum cost and labor. Programs for all gases and measuring ranges are permanently stored in the memory of the controller. The user-friendly software program allows authorized personnel to select different configurations by a simple push of a button. Easy to install and easy to use The controll modules as well as the power supply and the common alarm module clip on to a DIN rail. The remote sensor heads and any alarm or recording devices connect to terminals on the front of the module. Each Statox 501 control module has three relays for alarm 1 and 2 and system failure (115 / 230 V AC / 2 A). An analog output for recorder or process control systems is also included. Measured values are displayed on a 4 digit LED-display. It is easy to program or calibrate the Statox 501! Just follow the menu! If intrinsically safe transmitters are to be installed in division 1 areas, they can be connected via intrinsically safe repeaters. 24 V power supply as well as the signals for the common alarm module are transmitted via bus from one module to the next. All terminals are easily accessible from the front. Field proven sensors for reliable gas detection Compur manufactures electrochemical sensors for the detection of oxygen deficiency and toxic gases. These sensors generate an electrical current proportional to the actual gas concentration. The remote sensor heads are designed as intrinsically safe certified 4 - 20 mA transmitters and have an integrated concentration display. Combustible gases can be detected with a variety of catalytic beads (pellistors) or infrared technology. The sensor heads are certified "Ex d" or "Ex de" and can be connected directly to the control module, even if they are to be used in classified areas. The control module can supply and operate different designs of catalytic sensors. With so many possibilities, the system can easily be tailored to suit your individual application needs. Easy maintenance saves time and money Maintenance of the 4 – 20 mA transmitters is very easy. A one-man calibration or replacement of the sensors can be done without further precautions, even in classified areas. Accessories A range of wall-mount cabinets for a maximum of 5, 8 or 32 controllers as well as a 19”-carrier, ensure an easy professional installation. -20 - +60 °C

Request for a quoteResults for

Electric generators - Import exportNumber of results

36 ProductsCountries

Company type

Category

- Electricity generators (10)

- Boilerwork (4)

- Bottling and filling - machinery and equipment (3)

- Measurement and control instruments (2)

- Electricity generation (1)

- Magnets (1)

- Electric and electronic components - machines for manufacturing (1)

- Heat exchangers (1)

- Electrical components and parts (1)

- Heating, domestic - installations and equipment (1)

- Hot-air generators (1)

- Laboratory equipment and instruments (1)

- Laser - cutting and welding machines (1)

- Medical electronics - apparatus and equipment (1)

- Packing and packaging - machinery and equipment (1)

- Pipes and tubes, aluminium (1)

- Refrigeration plants and equipment, commercial and industrial (1)

- Stamping - steels and metals (1)