- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drainage systems and equipment

Results for

Drainage systems and equipment - Import export

FLOTTWEG SE

Germany

Sewage sludge dewatering offers enormous potential savings for operators of sewage treatment plants. Dewatering sludge means reducing the quantity of sludge for disposal. Depending on system capacity, 1 percent more dry substance can lead to cost savings in the five- to six-digit range. The dewatering performance of the Flottweg Xelletor Series is significantly better than even its predecessors. It sets new benchmarks for throughflow, dry substance, and polymer and energy consumption. The Xtra in performance at low consumption in comparison with our high-performance C Series: ►Xtra dewatering performance: Up to 10 percent less sludge volume due to higher total dry solids in dewatered sludge ►Xtra polymer savings: Up to 20 percent savings on flocculant consumption ►Xtra capacity: Up to 15 percent more throughflow ►Xtra energy savings: Up to an additional 20 percent energy savings

Request for a quote

FLOTTWEG SE

Germany

We know the special requirements of the wastewater industry. Flottweg therefore decided to create a new decanter series solely manufactured for sludge separation, called the Flottweg C Series.

Request for a quote

FLOTTWEG SE

Germany

In small sewage treatment plants, investment costs play a decisive role. In stationary dewatering systems, for example, the construction of a new building can be significantly costly. You can avoid those costs with mobile container systems for sludge dewatering. Container-based solutions are a practical alternative to fixed dewatering installations.. A container is a true "plug and play" option – just connect it and start dewatering. ►Sludge dewatering in a one-man operation: comfort and personal safety, with control of the dewatering installation directly on-site. ►Year-round comfort: raised roof; insulated walls and roof, consistent use of stainless steel. ►Minimized maintenance effort: The roof can be opened by a single person using a manual hydraulic lifting system; the decanter can be opened with a crane built into the container. ►Optimized for operation in the smallest of spaces ►Easy transport with all current truck types

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Meander Water Retention Board FKM 30 is used for multi-layered extensive green roofs.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

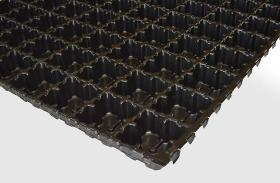

Optigrun Protection and Drainage Board FKD 60BU under public roofs with and without roof pitch, filled with Drainage Material Perl 8/16 or chippings 2/5Under public roofs with and without roof pitch, filled with Drainage Material Perl 8/16 or chippings 2/5 Suitable for non-pitch roofs Rapid draining of excess water Vapour permeable - suitable for inverted roofs Lightweight super structure with high drainage capacity Surrounding edge overlaps Filling without risk of shifting apart Cross and T-joints possible - minimal offcuts

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Drainage and Storage Board FKD 60BO under intensive roof greening in multi-layer construction and temporarily drivable gravel lawn without gravel base layer filled with Drainage Material Perl 8/16Under intensive roof greening in multi-layer construction filled with Drainage Material Perl 8/16 Under temporarily drivable gravel lawn without gravel base layer filled with Drainage Material Perl 8/16 Unfilled installation under intensive roof greening is possible with a substrate height of up to 400 mm in combination with Optigrün Filter Fleece FIL 300 (it is not possible for vehicles of any kind to drive over the unfilled Optigrün Drainage and Storage Board FKD 60BO) Suitable for non-pitch roofs Rapid draining of excess water Vapour permeable - suitable for inverted roofs Lightweight super structure with high drainage capacity Surrounding edge overlaps Filling without risk of shifting apart Cross and T-joints possible - minimal offcuts

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Drainage and Storage Board FKD 40 is installed beneath extensive green roofs and single-layered intensive green roofs for drainage and water storage.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Protection and Drainage Board FKD 25 plus is installed beneath traffic surfaces and pathways. Also suitable for inverted roofs.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Drainage and Storage Board FKD 25 for use on extensive green roofs with single- or multi-layer construction and under path surfaces (can be walked on).On flat roofs up to 5 % roof pitch In a triple-layer structure with filter fleece FIL 105 and extensive multi-layer substrate E Under thin-layer pedestrian pathways in gravel beds without bedding material The large naps can face either downwards or upwards Suitable for non-pitched roofs Suitable for use on inverted roofs With water reservoir

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Protection and Drainage Board FKD 12UK under public areas on buildings used by vehicles. Suitable for inverted roofsOpen to diffusion Incl. PP thermally strenghended with 23 l/m² x s flow rate (GRC 4) On roof surfaces with a minimum of 2 % regular gradient of the sealing plane Prevents accumulation of water Without water reservoir function

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Protection and Drainage Board FKD 12 as a drainage element beneath traffic areas with car and truck usage, intensive green roofs, balconies and terraces.Incl. PP filter fleece with 23 l/m² x s flow rate (GRC 4) Incl. PE slip layer (friction coefficient <0,6) as first slip layer On roof surfaces with a minimum of 2 % regular gradient of the sealing plane Prevents accumulation of water CE-marked Without water reservoir funktion

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Protection and Drainage Board FKD 10GF under pavement areas used for walking, under vegetation areas with no need for a water reservoir but increased pressure load and vertically along ascending, filled structural components.Protection and Drainage Board incl. PP filter fleece with 100 l/m² passage capacity (GRC 2) Incl. PE film adhered on the reverse As drainage element under floor surfaces used on foot with increased frequency For vegetation areas with no need for a water reservoir but increased pressure load Vertically along ascending, filled structural components Prevents accumulation of water Without water reservoir function

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Protection and Drainage Board FKD 10UK as a drainage element under floor surfaces used on foot and under vegetation areas with no need for water reservoir but increased pressure load.Open to diffusion Incl. PP thermally strenghtended with 75 l/m² x s flow rate (GRC 2) On roof surfaces wiht a minimum of 2 % regular gradient of the sealing plane Prevents accumulation of water Without water reservoir functíon

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Protection and Drainage Board FKD 10 is used as drainage beneath frequently used pathways and on vertical building components. Incl. PP filter fleece with 75 l/m² x s flow rate (GRC 2) On roofs with a minimum of 2 % regular gradient of the sealing plane Prevents accumulation of water Without water reservoir function

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Especially in rapidly changing markets, it is all the more important to rely on a partner with many years of market and expert knowledge. With semi-mobile container plants – similar to mobile filter presses – we support you in defying the rapid changes on the market in order not to jeopardise your core business. Semi-mobile filter presses can be used flexibly and are also quickly ready for operation. Furthermore, the semi-mobile filter press is fully equipped and immediately ready for operation after connecting to sludge, water and power supply. MSE Filterpressen® engineers and manufactures the plants for individual customer requirements. In this way, the best possible result can be achieved for every task. The semi-mobile filter press from MSE is available in various designs. The sizes of the semi-mobile filter presses are available up to a maximum size of 1500 format. This corresponds to about 100 chambers, i.e. about three cubic meters of chamber volume.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

MSE stainless steel filter presses comply with the high hygiene and purity standards both in design and processing. With the stainless steel filter press, all components in contact with the product are covered with high-quality stainless steel. This also provides optimum protection against corrosion. FDA-COMPLIANT SOLID-LIQUID SEPARATION WITH THE MSE STAINLESS STEEL FILTER PRESS A large number of materials with different properties are used in the food sector in particular. Here, especially care must be taken to ensure that no ingredients are released into the food. The law stipulates a FDA certification for this. Accordingly, all materials used must be FDA-certified. The FDA certification stands for high purity and durability. Each component such as the filter plates, filter cloths and piping systems complies with the FDA guidelines. This contributes to high hygiene and safety requirements.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

The hot filter press combines the standard process steps of a membrane filter press, (filtration, filter cake washing and squeezing), with the additional function of a thermal filter cake drying (TCD). As a result, all process steps are carried out in one plant, the hot filter press. Dewatering and drying of the resulting filter cake is thus done without a downstream drying process. Cost-intensive and time-consuming vacuum contact drying is therefore no longer necessary. FUNCTIONAL PRINCIPLE OF THE HOT FILTER PRESS – WITH THERMAL FILTER CAKE DRYING In contrast to the conventional method, the system consists of membrane filter plates and heat exchanger plates, which are installed alternately in a filter press. For thermal drying, hot steam and/or oil is applied to the working space behind the membrane and the filter cake is thermally dried accordingly. The advantage of this process is that a high dry matter content (DM content) of over 90% is achieved.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MSE FILTERPRESSEN GMBH

Germany

Based on the decisive properties of the flexible material, the rubberised filter press is mainly used for the filtration of particularly aggressive suspensions and environments. The aggressive suspensions include, for example, solvents or acids. In this context, the conventional painting of the steel parts is no longer sufficient. THE RUBBERIZED FILTER PRESS OF MSE AS PROTECTIVE MEASURES AGAINST AGGRESSIVE SUSPENSIONS In a complex process, the load-bearing filter press components are coated with a layer of 3mm thick plastic. In the case of the rubberised filter press, the hydraulic stands, feed stand, pressure plate and supporting beams are hard rubberised and the smaller components are made of polypropylene. It is also possible to rubberise only the components in contact with the product, such as the feed stand and the pressure plate. The composition of the rubber coating depends on the special surface requirements of our customers.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Mobile filter presses are particularly suitable for dewatering sludge from several plants at regular intervals or for compensating capacity peaks and bottlenecks. The fact that mobile filter presses are not subject to approval obligation and are therefore quickly and unbureaucratically available is particularly interesting. MSE mobile filter presses are fully equipped and immediately ready for operation after connection of the sludge, water and power supply. In this way, the best possible result can be achieved for every task. Mobile filter press plants can be implemented in many different designs. The sizes of the mobile filter presses are available up to a maximum size of 1200. This corresponds to about 100 chambers and about three cubic meters of chamber volume. The plants are equipped with suction and pressure-side inline mixers. The PLC plant controls the conditioning parameters in proportion to pressure and/or volume.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

With its structural protection measures and its specific requirements the ATEX filter press complies with the ATEX directives. As a result, these types of filter presses are designed for a high level of safety and explosion protection. ATEX „ATMOSPHÈRES EXPLOSIBLES„ ATEX derives its name from the French term „ATmosphères EXplosibles”. It consists of two EU directives governing explosion protection and thus the equipment and working environment in an environment with an explosive atmosphere. ATEX filter presses are especially used in filtration processes in the chemical, petrochemical, oil and gas extraction, mining, food and waste water sectors. With their design, as well as the selected materials, they comply with all the requirements of the ATEX certification in potentially explosive areas.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Semi-automatic filter presses represent a simplified and cost effective solution for the reliable operation with respect to operation and safety measures. This type of filter press is distinguished by a special, a rail-mounted two-hand control panel. The filter press with two-hand control is used in particular when the space on site is limited or a higher degree of automation is not required. Accordingly, a conventional version of the protective device is no longer effective. REDUCED PROCUREMENT COSTS AND SIMPLE OPERATION – THE SEMI-AUTOMATIC FILTER PRESS WITH TWO-HAND CONTROL FROM MSE Based on the safety technology requirements, an intelligent two-hand control is implemented, for example, for moving the filter plates by means of automated plate shifter. This functional principle thus prevents the operator from reaching into the working area. Complicated mechanical designs including further safety measures are not necessary.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Fully automatic filter presses are specifically designed for applications in which a continuous operation and fast cycle times are essential and therefore crucial. MSE fully automatic filter presses provide a high degree of automation while providing uninterrupted operation at the same time. FULLY AUTOMATIC FILTER PRESSES FROM MSE INCREASE PRODUCTIVITY AT THE SAME TIME REDUCING PERSONNEL COSTS The operating time of a fully automatic filter press is 24/7. The option of the simultaneous filter plate opening system, for example, helps to realise a particularly fast cake release reducing the cycle time to a minimum. The result is a high-speed filter press that allows increased production per unit area of filter. For this reason, these machines are used in applications with highly filterable products where high filtration speeds are required. These include, e.g. mining concentrates and residues.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

MSE Filterpressen® offers a wide range of filter presses with sidebar technology suitable for both standard and medium duty and for heavy-duty performance levels. Maximum flexibility is provided by choosing between simple manual to fully automated MSE filter press designs. MSE chamber filter presses are upgradable in terms of modules and features and can be customized to your specific needs and requirements. HIGH PERFORMANCE AND HIGH DEGREE OF CONFIGURATION FOR YOUR CHAMBER FILTER PRESS The chamber filter press can be configured as required depending on the series. Taking different influencing factors into account, chamber filter presses achieve a solids content in the filter cake from 30 to over 50 percent. The intelligent filtration principle leads to immense cost savings in the waste water sector, for example. The operation of the chamber filter press is designed for a feed pressure of up to 15 bar in order to successfully filter even the finest particles.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

CellTRON® FOR MAXIMUM FILTRATION REQUIREMENTS The basis of this plant is a membrane filter press. The new product series is equipped with an innovative filter press emptying system with lifetime error message, an automated filter cloth washing system with implemented CIP cleaning function as well as an automatically opening and vacuum-proof housing. In contrast to conventional filter presses, this new development guarantees an almost gastight encapsulation of the filter press. The filter press thus meets the specific requirements for dewatering special (metal) sludges. In addition to standard configurations for battery cell production, this technology series is also suitable for demanding applications that require the highest safety and efficiency standards. These include volatile, dust explosive products as well as substances with toxic and radioactive properties but also pharma food products and hot suspensions (≥130°C).

Request for a quote

SANHA GMBH & CO. KG

Germany

The exclusive MASTER 3 sound-insulating drain system from SANHA consists of high-quality three-layer pipes and modern fittings. The drain pipes are constructed with three perfectly matched layers that work together to meet all the demands that a drain system is subjected to in the construction of a modern house, apartment and industrial building. Each layer optimises the properties of the pipe: The smooth inner layer prevents encrustations and is partly responsible for the good sound insulation properties. The solid middle layer is extremely robust and the brown outer layer provides excellent impact resistance even at low temperatures. The sealing ring consists of styrene-butadiene rubber (SBR).

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities for you. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R15 ✅ Industrial robot applications for components up to 8 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quoteResults for

Drainage systems and equipment - Import exportNumber of results

27 ProductsCountries

Company type