- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- die casting part

Results for

Die casting part - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

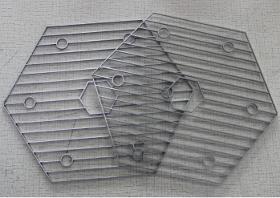

These are the supports parts used for machine,using casting process, the complex structure.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Forged parts made of steel, stainless steel and aluminum including mechanical processing. Pressed brass blanks including mechanical processing, also on rotary transfer machines. Sintered parts made of sintered bronze, sintered porous brass and stainless steel. Filter elements for air, liquids and fuel made of sintered ball material or mesh.

Request for a quote

TRIBO-CHEMIE GMBH

Germany

Release agent based on 25 years of product development Temperature Range 150 °C bis 380 °C Alloy Al, Mg, Zn Properties and Advantages • high process reliability due to extremely stable micro-emulsion • excellent release effect, bright castings • parts perform unproblematically in joining processes

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Testing equipment for quality control and material optimization of die-cast aluminum parts, strength test Quality control of injection molded parts; Predetermined breaking point Hand control robust construction Evaluation via GMV2

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Its 6 mm tool-receiving socket, the stable finish and the almost maintenance-free reciprocating engine make this filer an indispensable tool even when under extreme and continuous strain - for instance rough machining of casted parts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Impregnation systems to close micropores in metal castings as well as in copper, aluminium or magnesium alloy castings. The parts to be impregnated are fixed in baskets. The latter are transported by a special crane system as well as with reservoir roller conveyors. Excess material is removed by centrifuging of the baskets. The impregnating agent remaining in the pores in fluid form is hardened by heating in a hot water bath. The process sequence runs fully automatically under a microprocessor control.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The Systems comprise the entire casting process: Preparation of the material components resin and hardener (conveying, homogenization, degassing), production of the reactive mix and casting of the parts under vacuum/atmosphere. Any resin system can be processed, also with strongly disproportional mixing ratios.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The Systems comprise the entire casting process: Preparation of the material components resin and hardener (conveying, formulation, homogenization, degassing), production of the reactive mix and casting of the parts under vacuum/atmosphere. Any resin system can be processed, including fillers, and also with strongly disproportional mixing ratios.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

In-line conveyor ovens: Pallets pass through the oven one after the other. Automatic batch ovens: The oven is charged with pallets while kept at a temperature below the gelation temperature. After the last pallet has been loaded, the temperature cycle is started for the whole lot. The oven is emptied in a rapid process after the complete temperature profile has been run through. Stack ovens: Pallets are loaded into the oven. When each row has been filled, all the rows of pallets are lifted up by one level. When one row of pallets has reached the uppermost position of a temperature range, it is pushed into the next temperature zone and from here is lowered down in fixed time cycles and unloaded. Serpentine conveyor ovens: Pallets are loaded into the oven in fixed time cycles and pass through the individual temperature zones.

Request for a quote

SANHA GMBH & CO. KG

Germany

The SANHA series 4000 and 5000 "SA" consist of tried and trusted solder and transition fittings for copper pipes according to EN 1057 and EN 13348 for hard and soft soldering. All products are certified according to many national and international certification bodies. SANHA capillary solder fittings are manufactured from copper (Cu-DHP, CW024A for moulded parts) and copper alloys CC499K (threaded parts, cast parts) and fulfill all requirements of BS EN 1254.

Request for a quote

SANHA GMBH & CO. KG

Germany

The SANHA series 4000 and 5000 „SA“ consist of solder and transition fittings for copper pipes according to EN 1057 and EN 13348 for hard and soft soldering. All products are certified according to many national and international certification bodies. SANHA capillary solder fittings are manufactured from copper (Cu-DHP, CW024A for moulded parts) and copper alloys CC499K (threaded parts, cast parts) and fulfill all requirements of BS EN 1254.

Request for a quoteResults for

Die casting part - Import exportNumber of results

12 ProductsCountries

Company type

Category

- Electric and electronic components - machines for manufacturing (2)

- Pipe and tube fittings - non-ferrous metal (2)

- Cements, special (1)

- Furnaces, ovens and kilns, electric (1)

- Measurement and control instruments (1)

- Spare parts for diesel engines (1)

- Surface treatment - machinery and equipment (1)

- Tools, pneumatic (1)

- Vehicles - mechanical components and parts (1)