- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- deep groove ball bearing

Results for

Deep groove ball bearing - Import export

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

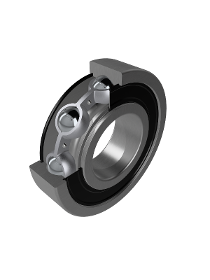

The use of high-precision radial groove ball bearings is especially recommended when axial forces are supported in two directions, but the installation space makes the use of a spindle bearing pair impossible; plus when the best-possible guide for rotating components is needed, but the RPM requirements are less important. Depending upon the load capability and the installation space available, GMN provides deep groove ball bearings in sizes 60 and 62 as per DIN 625. A large selection of various cages, lubricants and covers make it possible to adapt GMN deep groove ball bearings to any application.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Single row deep groove ball bearings (Typ: 6000/6200/6300) Double row deep groove ball bearings (Typ: 4200) RDEEP GROOVE BALL BEARING Single row deep groove ball bearings (Type: 6000/6200/6300) Double row deep groove ball bearings (Type 4200) Deep groove ball bearings are wide ranging, non-separable bearings with solid outer rings, inner rings and bearing housings. These simply built products, steadfast in operation and maintenance friendly, are available as single and double row as well as sealed and open. In technical production, open bearings can have a recess on the outer ring for seals or cover rings. Due to their low moment of friction, deep groove ball bearings are suited to high speeds. Single and double row ball bearings are the most utilised anti-friction bearing. They are simple in construction, non-separable, suited to high speeds and unsusceptible in operation and maintenance. Narrow lubrication between running grooves and balls.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on our many years of experience in developing and manufacturing high-quality machine components, GMN has specialized in the area of high-precision ball bearings as well as the production of high-performance and long-lived deep groove and spindle ball bearings to meet – or even exceed – the highest precision classes P4 and ABEC 7. Certification under international standards ensures the highest precision in the development and manufacturing of GMN ball bearings and guarantees constant, outstanding qualities related to speed suitability, stability and longevity. The broad product range includes a large selection of standard solutions as well as requirements-tailored special designs.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

In the mining sector severe operating and environmental conditions require extremely robust bearings. Bearings for mining industry are used for bucket wheel excavators, draglines, conveyor belts, trucks, stackers, transport equipment, loaders, longwall shearers and hoists. The mining industries use many types of bearings: roller bearings, deep groove ball bearings, spherical roller bearings and tapered roller bearings. DEEP GROOVE BALL BEARINGS The mining industries use belt conveyors for transporting bulk materials. The conveyors run on idlers and a lot of them extend over many kilometers; thus the number of idlers needed may be very large. The deep groove bearings (design 2ZR and 2RS) are sealed by dust shields and seals on both sides, and filled with grease for a long service life. SPHERICAL ROLLER BEARINGS In the mining sector severe operating and environmental conditions require extremely robust bearings. Mining machinery faces some of the toughest terrains.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

KIS deep groove ball bearings are characterised by their high load carrying capacity and speed stability. Depending on the requirements of your application, they are available in different variants and in both radial and axial design. Our single row deep groove ball bearings are available in open and sealed designs. Open bearings are maintenance-free, while sealed bearings offer better corrosion protection. Single row deep groove ball bearings can support both radial and axial forces. Our double row deep groove ball bearings feature a higher radial load carrying capacity. They are used when the radial load carrying capacity of single row deep groove ball bearings is not sufficient. Axial deep groove ball bearings are suitable for supporting particularly high axial loads. They are available in both single and double direction. Single direction thrust ball bearings can only support axial forces, while double direction thrust ball bearings can support both radial and axial forces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROS ROLLENTECHNIK GMBH

Germany

In addition to precision deep groove ball bearings, ROS also employs self-aligning ball bearings and spherical roller bearings for its heavy load rollers with internal bearings. In addition to a selection of different tube and shaft designs, powered rollers are also available for use.

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

In addition to precision deep groove ball bearings, ROS also employs self-aligning ball bearings and spherical roller bearings for its heavy load rollers with internal bearings. In addition to a selection of different tube and shaft designs, powered rollers are also available for use.

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

Spare parts for conveyor systems Bearing inserts from — galvanized sheet steel (with oiled ball bearing, in antistatic design) — Plastic, grey (polypropylene), with black plastic seal (polyamide) and stainless steel balls — Plastic, black (polypropylene), with black plastic seal Labyrinth (polypropylene) and RS deep groove ball bearing (in antistatic design) — Plastic, blue (polypropylene) with blue (polypropylene) and double stainless steel ball row Pipe diameter: — 20x1.5 mm — 30x1.5 mm — 30x2 mm — 40x1.5 mm — 40x2.3 mm — 50x1.5 mm — 50x2.8 mm — 60x2 mm Axle diameter: — 6 mm — 8mm — 10mm — 12mm

Request for a quoteResults for

Deep groove ball bearing - Import exportNumber of results

9 ProductsCountries

Company type