- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cover seals

Results for

Cover seals - Import export

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

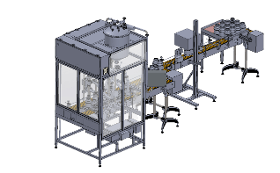

Challenger 200B is semi automatic linear system It’s designed for filling liquid or pasty products in plastic jar With five work stations: Adding jar on conveyor manually, filling, adding covers on jar manually, sealing cover (induction seal), Exiting.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

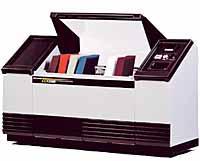

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The measuring element of this load cell consists of a double bending beam with strain gauges, the resistance of which changes with the application of force. Upon applying a voltage to the strain gauge bridge, the change in the strain gauge resistance is converted into output voltage, which is directly proportional to the force. The strain gauges and the entire measuring element are protected from water spray by metal cover including sealing material. The tensile or compressive load to be measured is applied to the sensor element through the M6 threaded hole located on each end face. The load can be applied easily, along the sensor axis. This serves to prevent falsification of the measured values. Overload protection can be realized with little effort using a mechanical stop. FEATURES Measuring ranges from 0 … 20 N to 0 … 880 N Relative non-linearity: ±0.25 % F.S. Many load cycles Protection class IP54 Excellent price-performance ratio burster TEDS optionally available

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We manufacture customer-specific molded parts made of rubber, silicone and elastomer composite parts in small and large series production according to your sample or drawing. Molded rubber parts are generally characterized by their good formability, chemical resistance, pressure and abrasion resistance and good electrical properties. We advise you in detail on the selection of the suitable material, with a view to the functional description, temperature resistance, chemical requirements, weather influences and resilience. Our molded parts are used in all industries, such as the automotive industry, medical technology, mechanical engineering and electronics industry. We offer customized parts: Protective covers for input devices, Rubber seals and rings, Grommets, flanges, bellows, Form Tubes, Rubber damper, PU molded parts (e.g. wheels and rollers) Combined rubber-metal parts / rubber-plastic parts, etc.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to their extremely compact design, these load cells can be used wherever static or dynamic load forces have to be measured in very tight spaces. Model 8416 is perfect for use in micro-technology and just as suitable for measuring tasks in the research and development sector. The ultra-miniature compression load cell model 8416 is a flat, circular disc, the bottom of which is sealed with a cover. The load application button for receiving the compression forces is an integrated part of the sensor. The sensor element inside the body carries a strain gage full bridge which outputs voltage directly proportional to the measurement variable upon application of force. The short nominal measurement distance of the ultra-miniature compression load cells due to their design provides a high degree of rigidity. If needed, the nominal characteristic value can be standardized in the sensor connection cable.

Request for a quote

RUDOLF UHLEN GMBH

Germany

• The aluminium hard hat bracket with cover fits all standard hard hats • The bracket is easy to attach to the hard hat • Secure fit on the hard hat due to a powerful tension spring • The bracket is made of robust aluminium profiles and is heat and corrosion resistant • The broad overlapping of the profiles ensures a good seal at the top. The cover provides an additional seal against dust and debris • The face shields can be lifted into 4 positions • The face shields are attached with a rotating fastener or with a clip fastener

Request for a quote

BÜRKLE GMBH

Germany

Screw-on closure with tamper-evident ring for compact jerrycan. Screw-on cover made of PP, seal made of PE, thread DIN50. The closure offers protection against tampering and a guaratee that the container has not been opened before, since the snap ring is visibly broken the first time the container is opened.

Request for a quote

VKF RENZEL GMBH

Germany

The pavement WindSign "QS I" was technically updated and is now available as pavement WindSign "Seal". The stronger cover foil is fixed with screws on the top profile and cannot slip down anymore. The covers can still be exchanged if necessary. Two sticky pads are implemented in the upper part of the frame. Those make sure that your posters will be held in place during installation. Of course the pads are reusable. The optimised poster stand comes in new visual appearance. All pavement signs are made with a sturdy back-wall and 2 non-glare, UV stabilised front covers. The new sealant makes the display waterproof. The base can be filled with either water or sand and is movable on 2 wheels when tilted. The strong springs allow for the highest grade of stability even in “stormy” weather conditions. Posters can be exchanged quickly by opening the aluminium click frame profiles. The header board is inserted into the upper groove of the pavement sign and fixed with screws.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

The barrel coupling consists of a sleeve provided with semicircular toothing around its internal diameter and a hub that is externally toothed in a similar way. A series of cylindrical barrels, of hardened steel, are inserted in the holes formed by this toothing to act as power transmission elements. Covers with their corresponding special seals serve to assure the perfect tightness of the inner zone, preventing the penetration of dust and guaranteeing the continuity of the necessary lubrication. The most important characteristics and adcantages of barrel roll couplings: for alignment error compensation for ease of assembly especially wear-resistant with high durability minimises effect of alternative bending of the torque on the toothing designed for bearing large radial loads by distributing them over large barrel support surfaces Perfect tightness of the inner zone prevent the penetration of dust We are glad to see that you are interested in our product line and are happy to...

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

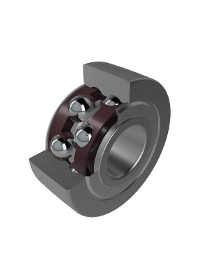

Our KIS track rollers are available as self-retaining, single or double row ball bearings with particularly strong outer rings. In addition to high radial forces, they also absorb axial forces in both directions. Track rollers are characterised by their robust construction featuring particularly thick-walled outer rings with a crowned outer surface (alternatively with a cylindrical outer surface or outer profile). They are designed to carry high radial loads and also tolerate axial loads that can arise due to minor misalignments, skewing or short-term start-up shocks. The assembly is constructed with a fixed inner ring mounted on axles. In this case, the track rollers are not installed in a housing bore, but are supported on a flat raceway (mating track). To ensure a reliable seal, the track rollers are fitted with a lip seal or cover discs on both sides. This prevents the ingress of dirt, dust and other contaminants while maintaining lubrication inside the bearing.

Request for a quote

4CR INTERNATIONAL GMBH

Germany

For covering and lifting of rubber seals, as well as in inaccessible curved areas, easy to use. Protect the vehicle interior from overspray. Individually cut to the desired size, horizontal and vertical. Temperature resistant up to 80 °C.

OBO BETTERMANN HOLDING GMBH & CO. KG

Germany

Cassette R9, with cord outlet, V2A, floor covering 25 mm, as connection unit according to EN 50085-2-2, for installation in mounting opening in underfloor installation systems and raised and cavity floors indoors, for use in dry rooms with dry-cleaned floors, height adjustable to top floor edge, consisting of: Cassette with slip-proof cord outlet with handle and inserted sheet steel cover, cassette with seal, cassette frame with integrated snap-in ladder for installation of 3 universal supports for 9 single installation devices with support bracket or 12 Modul 45 devices and cable guide bracket with integrated scuff protection, 4 levelable supports. Classification according to EN 50085-2-2: Application area: for dry floor care (6.101.1). IP protection class: IP 30. IK protection class: IK 10. Load capacity: 3,000 N (6.102.7) 5.000 N (6.103.3)

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Is widely used in Pharmaceutical, Cosmetics, Food and Chemical industries etc. It is suitable for mixing dry powder or granular materials with perfect flowing properties. Servo conveyor system Base holds the mixing vessel which made of stainless steel (304) Cylindrical vessel with two conical bases. The vessel rotates on horizontal axis. And the Inner edges wrapped to prevent accumulation of the material. Circular cover, sealed with silicone gasket Discharge hole fitted with manual butterfly valve Guardrail (Profile) connected to a safety sensor to prevent the vessel from rotation while opening the rail Sensor system stops the mixer in the desired position (The discharge hole to the bottom) Available certification up on your request UL, CE, GMP, FDA, ASME.

Request for a quote

WHITE STEEL GMBH

Germany

Is widely used in Pharmaceutical, Cosmetics, Food and Chemical industries etc. It is suitable for mixing dry powder or granular materials with perfect flowing properties. Servo conveyor system Base holds the mixing vessel which made of stainless steel (304) Cylindrical vessel with two conical bases. The vessel rotates on horizontal axis. And the Inner edges wrapped to prevent accumulation of the material. Circular cover, sealed with silicone gasket Discharge hole fitted with manual butterfly valve Guardrail (Profile) connected to a safety sensor to prevent the vessel from rotation while opening the rail Sensor system stops the mixer in the desired position (The discharge hole to the bottom) Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Single row deep groove ball bearings (Typ: 6000/6200/6300) Double row deep groove ball bearings (Typ: 4200) RDEEP GROOVE BALL BEARING Single row deep groove ball bearings (Type: 6000/6200/6300) Double row deep groove ball bearings (Type 4200) Deep groove ball bearings are wide ranging, non-separable bearings with solid outer rings, inner rings and bearing housings. These simply built products, steadfast in operation and maintenance friendly, are available as single and double row as well as sealed and open. In technical production, open bearings can have a recess on the outer ring for seals or cover rings. Due to their low moment of friction, deep groove ball bearings are suited to high speeds. Single and double row ball bearings are the most utilised anti-friction bearing. They are simple in construction, non-separable, suited to high speeds and unsusceptible in operation and maintenance. Narrow lubrication between running grooves and balls.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

EXTREMELY GENTLE PROCESSINGRotating barrels offer a cost-effective and technically ideal solution, particularly when processing small parts in medium batches. This helps you get fine surfaces with neatly rounded workpiece edges, thanks also to the relatively long processing times. Trowal rotating barrels are also excellent for fine finishing and polishing. SOPHISTICATED TECHNOLOGY The barrel body is an octagonal, welded, biconal structure. It generates a triple sliding action in the mass of abrasive media with the workpieces to be processed. The lining consists of tear-proof rubber or PU, with the tight-sealing safety cover made of polyurethane. BARREL BODY WITH LIFTING AND LOWERING DEVICE The automatic lifting and lowering device lets you quickly feed and empty the barrel body. This is a major advantage, especially when processing times are short and when you are operating multiple rotating barrels.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

- Compact construction - Product contacting parts can be made to customer specifications - Freely programmable filling nozzle movement and filling speed - Fully automatic cleaning process (CIP) Standard - CIP/SIP possible as option - Product feed via pressure vessel, pump, gravity or customer’s feeding system - Maximization of performance through double track container transport with the same number of filling positions - Tool-free, operator friendly format change - Modular design: product guiding components completely exchangeable by means of module wagon simply and quickly (avoiding cross-contamination) - Vapor extraction possible - Explosion-proof execution optional - In the case of container leakages, wet cleaning of the machinery, there is no carryover into the machine sub-structure, due to welded seal, inclined machine cover - Hot filling possible - Multi-component filling possible for diverse volumes

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cover seals - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Sensors (2)

- Packing and packaging - machinery and equipment (1)

- Adjustment - machine tools (1)

- Automation - systems and equipment (1)

- Bearings, roller (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Food industry - machinery and equipment (1)

- Industrial cabling (1)

- Moulds, plastic and rubber industry (1)

- Paints, synthetic resin (1)

- Plate glass and mirrors (1)

- Protective and work clothing (1)

- Stoppers and caps, plastic (1)