- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coil lines

Results for

Coil lines - Import export

GSW SCHWABE AG

Germany

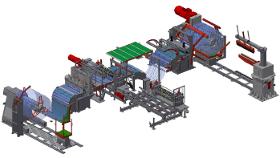

If you need two Coil Reels to hold one coil, you need a Heavy-Duty Coil Feed Line above all. One that is designed extremely robust and knows to subdue even materials of highest bounce and largest cross-sections.To ensure this, we have taken no heed to cost savings but went by the maximum principle: 2 Coil Reels with high-performance arbors retain the coils from left and right. 2 x 2 hydraulic arms secure them from top and bottom – each with eight tons pressure force, each with hydraulically driven snubber roll. The loading is done with one central lifting gear built into a super-duty running frame for the V-nest. Hydraulic manipulators with pivoting and bending function support the threading of the material. On the receiving end, a Pre-Straightener with 200mm work rolls takes over, after hydraulic edge guides have ensured central entry. Now, if someone asks us our definition of “heavy-duty”: We find 36.000 kilogram coil weight and 2.

Request for a quote

GSW SCHWABE AG

Germany

Slit metal often has camber. GSW builds Camber Straighteners, that help remove this defect. Coil Feed Lines that process small crosssections often only need minor straightening efforts. Here, we can help with pullthrough Straighteners also known as Flatteners. We usually mount them at the entrance of our Servo Roll Feeds or Air Feeds. Wire materials also often have a coil set – sometimes in two levels even. Single and dual Wire Straighteners help making such bent wires straight again.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

An innovation for decorative applications is the stripe coating on our narrow Coil Coating line at First American. This is a complete coil coating process in which we are able to leave tightly toleranced, unpainted stripes on the carrier strip. These give the decorative effect to the finished article, while the coated areas are coated with an adhesive system (e.g. automotive trim material or white coating with a defined black stripe, etc.). As always, all metal strips available on the market can be used as metal carriers; all coatings can also be used. This leads to a smart product, allowing you a multitude of new, innovative applications.

Request for a quote

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quote

GSW SCHWABE AG

Germany

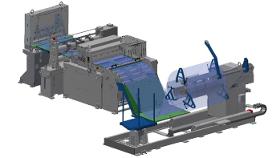

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quoteResults for

Coil lines - Import exportNumber of results

7 ProductsCountries

Company type