- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cnc turning- milling- machining

Results for

Cnc turning- milling- machining - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turn-milling compound machining flange

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in assemble flashlight accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The parts used in connecting pipe.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used in the valve accessories,the main function is to strengthen the valve,and ensure the normal flow of gas,to make sure the valve is working properly.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EWS WEIGELE GMBH & CO. KG

Germany

Make any centric or eccentric form desired 4, 6, or 8 edged, polygonal or free form with the EWS Multiform on the CNC turning/milling machines Free forms that used to be impossible can now be made with EWS Multiform on turning/milling or machining centres. For a six-edge outside the centre or a four-edge in the centre, additional processing steps such as reaming or eroding were necessary up until now. If a position change was also needed, complicated devices were needed for processing. This is now all possible with one chuck. What is behind this? EWS Multiform uses a custom internal cam disc unit to produce the required form. For conventional geometry like squares or hexagons, there are standard cam discs available. The cam forces the cutting tool to follow a path in order to get the desired geometric shape. Of course you can’t defy the laws of physics which means that there will be a small radius on the edges.

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL multi-roller tools are usually used for roller burnishing. Types G, R and RA machine cylindrical through and blind bores, stepped bores and cylindrical external surfaces including similar non-cylindrical surfaces. . RP, RK, RKA and RKAK tools are designed for plane surfaces, cones and spherical surfaces. RH/RHA tools deep roll fillets and chamfers. FA tools deep roll large thread root radii. All ECOROLL multi-roller tools can be used on CNC turning, drilling or milling machines and machining centers or on conventional machine tools. They can be characterised by reliable functioning and high precision. Adjustment of diameters is very convenient, and only nominal lubrication is required. Futhermore, replacement of wear parts is very simple. This uncomplicated maintenance and short primary processing times enable significant time savings.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

5-axis/5-sided machining means the C 42 lends itself to be used in every application area. With traverse paths adapted to the workpiece size and perfectly designed for 5-axis applications, the C 42 is ideal wherever complex, close-tolerance components are required. This includes various applications in the tool and mould making, medical, aerospace, motorsport, machine sectors and other industries: The C 42 machining centre is at home in every area. The space-saving circular tool magazine integrated into the base body of the machine works according to the pick-up principle - thus enabling quick tool changes. In the standard version, the C 42 can hold 42 tools and can be extended to 192 pockets. The control panel can be easily adjusted to the respective user. Milling and turning in one clamping with the C 42 U MT dynamic model. Fully integrated rotary table that does not interfere with demanding milling processes and 5 axes simultaneously.

Request for a quote

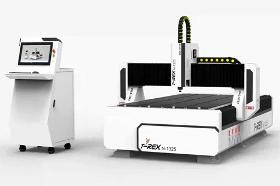

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quoteResults for

Cnc turning- milling- machining - Import exportNumber of results

10 ProductsCountries

Company type