- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping parts

Results for

Clamping parts - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Stampling device for welding work ■ positioning, centering & clamping of metal part, with integrated part scanning The individuel customized solution will be performed according to customer specification!

Request for a quote

FLUX-GERÄTE GMBH

Germany

The pump-kit MINIFLUX is designed for emptying IBCs via their floor-level outlet. Designed as an alternative to a vertical pump, the MINIFLUX can be used when an IBC is not accessible from the top. It is suitable for applications when gravity draining via the outlet tap is insufficient e.g. rapid dispensing or transfer to another container in a higher location. Power can ideally be provided by a commutator or compressed air motor. Product attributes: - For pumping out of IBCs directly from the outlet (with standard S60 x 6 thread) - Simple connection of the pump to the outlet by union nut - Compact design - Can be dismantled into two parts via clamp - Low overall weight of 1.2 kg - No need to mount pump to top of container - Does not require access to the container from above - Ideally combined with commutator motor or compressed-air motor Benefits: - Can be used where ceilings are low - Allows pumping directly from floor-level outlets, even when containers are stacked

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on its many years of experience in the development and production of high-quality machine components, GMN has chosen to specialize in the production of efficient, long-life sprag type freewheel clutches. The standardized model series offer a large selection of feature options to furnish effective freewheel clutch solutions for almost any field of application. The functional principle of sprag type freewheel clutches is based on static friction. A certain number of sprags are in constant friction contact with the connecting parts. Sprags are components with variable height. They are uprighted when the connecting parts are rotated and clamped between the connecting parts while there is static friction between sprags and connecting parts. The static friction is guaranteed by a specific geometry (clamping angle) of the sprags to the connecting parts. GMN sprag type freewheel clutches can be used as indexing clutches, backstops or as overrunning clutches.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles OP 10 with 4 part clamping on workpiece carrier unit OP 20 with 4 workpieces on 2 rotary tables (5-axis machining

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with a 4-part clamping device Editing the OP 20 after the turning process Piece time less than 90s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with 4 parts clamping Processing in one setup Machining time less than 82s per workpiece Machining with 4 spindles Tool monitoring for all tools takes place parallel to production time

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

CLAMPING DEVICES FROM THE EXPERTS. SAMAG OFFERS PROCESS-OPTIMIZED SOLUTIONS AND A COMPLETE ALL-ROUND SERVICE WHEN IT COMES TO DEVICE CONSTRUCTION. Complete machining of workpieces begins with the right clamping concept. Our engineers develop innovative solutions and clamping devices at the highest technical level. Processing complicated workpieces in efficient cycle times requires process-optimized clamping. We deliver technological solutions with longevity and all-round service. The workpieces are aligned, fixed and clamped hydraulically, pneumatically or mechanically. If several parts are processed at the same time, depending on the number of motor spindles, high-precision fixing, positioning and clamping of the parts is necessary. This is only possible with automated tensioning (e.g. hydraulic) and precise alignment of the devices.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNM are high precision plates for clamping small and thin parts for precision grinding and eroding. The low magnetic field height prevents magnetization of the processing tools. The chipboard is activated via a removable hex shifter. Structure: — Neodymium magnet system, steel body — transverse pole pitch 1.4 + 0.5mm — Holding power 100 N/cm2 — Magnetic field height 5mm — Pole plate wearing limit 6mm Recommendation: High-precision chuck for grinding and eroding

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNM are high precision plates for clamping small and thin parts for precision grinding and eroding. The low magnetic field height prevents magnetization of processing tools. The chipboard is activated via a removable hex shifter. PMNM palletising clamping plates are available in 3 versions: Structure: — Neodymium magnet system, steel body, — Transverse pole pitch 1.4+0.5 mm — Holding power 100N/cm² — Magnetic field height about 5 mm — Pole plate wearing limit 6 mm Recommendation: High-precision plate for grinding and eroding

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Compact and light-weight design for applications in which space is limited ▪ Available in 3 different sizes and covering all standard metric and imperial diameters between 4 mm and 32 mm / .16 inch and 1.26 inch ▪ Vibration/noise-reducing clamp body material with UV, ozone and weathering-resistant characteristics ▪ Advanced design with a film hinge allows the top part of the clamp body to open up and insert or replace the pipe, tube or hose without the use of force ▪ Embedded metal sleeve to ensure stability of the clamp assembly Please also ask for the Anti-Twist Feature to prevent turning of the components.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

These flange type units is made of stainless steel and fix the hub positively against their extended flange preventing axial movement during tightening. Applied wherever self-centering action and good concentricity of mounted components are essential and hubs with straight-thru bores are used. Available sizes: Metric series shafts from 20 mm to 150 mm dia. and Inch series for shafts from 1” to 4” diameter. Excellent concentricity and very easy to dismantle – these Locking Assemblies provide particularly good concentricity between the clamped parts. The flange is reinforced at the critical point, preventing bending or lifting of the inner ring during assembly and thereby ensuring easy dismantling. High rotation speed – the dimensional accuracy of the RfN 7013 Locking Assemblies allows their use in applications with higher rotational speeds. High radial loads – the material strength of the RfN 7013 Locking Assemblies makes them especially suitable for applications with high radial...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

These flange type units fix the hub positively against their extended flange preventing axial movement during tightening. Applied wherever self-centering action and good concentricity of mounted components are essential and hubs with straight-thru bores are used. Available sizes: Metric series shafts from 20 mm to 150 mm dia. and Inch series for shafts from 1” to 4” diameter. Excellent concentricity and very easy to dismantle – these Locking Assemblies provide particularly good concentricity between the clamped parts. The flange is reinforced at the critical point, preventing bending or lifting of the inner ring during assembly and thereby ensuring easy dismantling. High rotation speed – the dimensional accuracy of the RfN 7013 Locking Assemblies allows their use in applications with higher rotational speeds. High radial loads – the material strength of the RfN 7013 Locking Assemblies makes them especially suitable for applications with high radial loads. Axial hub positioning –...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

These Locking Assemblies are of single-taper design with a self-locking taper providing good self-centering action and concentricity, as well as increased torque capacity. A pre-centering hub section is not required. Integral push-off screws for disassembly are provided. This unit can be placed deep inside a bore due to it’s design. Available sizes: Metric series shafts from 20 mm to 150 mm dia. and Inch series for shafts from 1” to 4” diameter. Excellent concentricity and very easy to dismantle – these Locking Assemblies provide particularly good concentricity between the clamped parts. The flange is reinforced at the critical point. This prevents a bending and lifting of the inner ring during installation and therefore a good dismantling is ensured. Higher Rotation Speed – the Locking Assemblies remain true-to-form during assembly and so they are suitable in applications with higher rotational speeds. High radial loads – the material strength of the RfN 7013 Locking Assemblies...

Request for a quote

TAS SCHÄFER GMBH

Germany

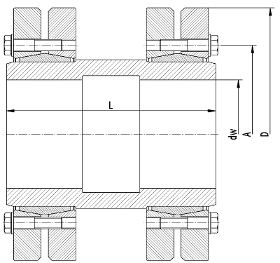

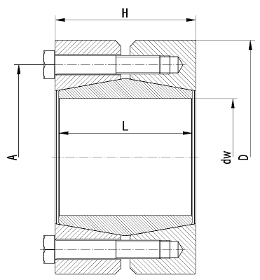

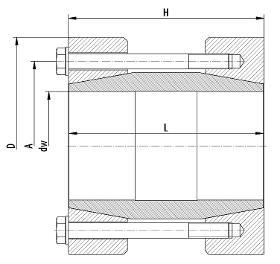

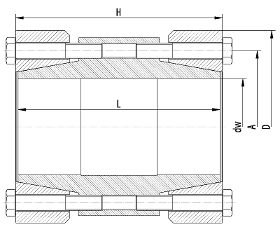

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. The external clamping system does not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean....

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated dove tailed slideway for the workhead and steady rest. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled drawer type coolant reservoir which can be drawn out for ease of cleaning. The machine base houses also the control panel for the motors. Grinding Spindle The permanently sealed and lubricated grinding spindle slides on a swivel plate which is provided with an integrated dove tailed slideway. The swivel plate is set to the desired valve angle by means of a wide spaced scale. Steady Rest An unique selfcentering steady rest is provided for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the slideway on the machine base to clamp the valve on that part of the valve stem which normally travels in the valve guide.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated dove tailed slideway for the workhead and steady rest. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled drawer type coolant reservoir which can be drawn out for ease of cleaning. The machine base houses also the control panel for the motors. Grinding Spindle The permanently sealed and lubricated grinding spindle slides on a swivel plate which is provided with an integrated dove tailed slideway. The swivel plate is set to the desired valve angle by means of a wide spaced scale. Steady Rest An unique selfcentering steady rest is provided for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the slideway on the machine base to clamp the valve on that part of the valve stem which normally travels in the valve guide.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated slideway for wheelhead. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled coolant tank which can be drawn out for ease of cleaning. Workhead and Steady Rest Both the workhead and the steady rest are adjustable along the swivel plate to clamp each valve on that part of the valve stem which normally travels in the valve guide. The combination of collet chucking and the unique Hunger steadying provides double support of long valves to ensure the ultimate in valve refacing accuracy. Automated Oscillation An oscillating equipment for automated power traverse of valve face across the grinding wheel is available as an option to ensure efficient stock removal and superior finish. The stroke of oscillation is infinitely adjustable.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -For horizontal & vertical usage-suitable for CNC controlled milling machines & large machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely -Gripper studs suitable for materials with a strength of up toapprox. 1000N/mm² Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -Fully compatible with the accessories of the LC/TC 160 series, for example gripper studs, universal gripper set & pull down sets -Grounded sides so that all sides can be used High-pressure spindle with mech. force amplifier for the safe clamping of raw parts in combination with gripping & pull down spring function -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 11 increments. At most, 2 revolutions are required to reach the max. clamping force - Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, gripper clamping or pull-down clamping are all possible -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested model -High-pressure spindle with power intensification. -Enlarged clamping span for secure clamping of unmachined parts -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER -Clamping near to neutral axes -Clamping jaws of forerunner are compatible -Clamping range of the middle fixed jaw groove: Max clamping width -176 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, gripper clamping or pull-down clamping are all possible -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -The TITAN 2 M is ground an polisched on all sides -High-pressure spindle with power intensification -Enlarged clamping span for secure clamping of unmachined parts -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER -Clamping near to neutral axes -Clamping jaws of forerunner are compatible

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical installation – suitable for both vertical and horizontal CNC-controlled milling machines -Lateral installation is also possible Product features: -Extreme accuracy for your machining -The TC vice is ground and polished on all sides -Clamping force can be preset in 11 increments – fine gradations for delicate workpieces. At most, one revolution is required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical installation – suitable for both vertical and horizontal CNC-controlled milling machines -Lateral installation is also possible Product features: -Extreme accuracy for your machining -The TC vice is ground and polished on all sides -Clamping force can be preset in 11 increments – fine gradations for delicate workpieces. At most, one revolution is required to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -Lateral installation is also possible Product features: -Extreme accuracy for your machining -Clamping force can be preset in 11 increments; fine gradations for delicate workpieces. At most, 1 revolution is required max. to reach the max. clamping force -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -Lateral installation is also possible Product features: -Extreme accuracy for your machining -Clamping force can be preset in 4 to 6 increments. At most, 1 revolutions are required to reach the max. clamping force -For clamping two identical parts (dimensional differences of up to ± 3 mm are compensated for) -Preselectable and reproducible clamping forces enable the workpiece position to be repeated within a tolerance of less than 0.01 mm Important: -Workpieces must be placed in both stations before clamping begins. -Type 90: drive head with finer clamping force presetting for delicate workpieces (6 increments)

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal installation – suitable for vertical CNC-controlled milling machines -Ideal for use on 5-axis machining centres -Reliable and fast clamping of unmachined parts, flame-cut and sawn materials with gripper jaws -Clamping of parallel pre-machined workpieces with optional step jaws -Gripper studs suitable for materials with a strength of up to approx. 1000N/mm² Product features: -Optimum accessibility for 5-sided machining thanks to the combination of compact base and large clamping width -Stamping and clamping in a single process, in the working area itself, without any additional accessories -The movable/pivot support jaw allows different workpiece contours to be clamped -Gripper studs can be changed without tools and are easy to adjust by hand -Operation with a torque wrench – max. 30 Nm -High-pressure spindle with power intensification

Request for a quoteResults for

Clamping parts - Import exportNumber of results

37 ProductsCountries

Company type