- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping mandrels

Results for

Clamping mandrels - Import export

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed the mandrel cutting machines of the SR series for cutting off sealing rings from injection-moulded or extruded tubes with different diameters. These machines are characterised by their unique processing method and high cutting quality. First, pre-extended "rubber tubes" are clamped onto mandrels. Due to the special design of the mandrels, the mandrel can be set up and removed quickly and without special previous knowledge. The mandrels are then automatically clamped in the machine between rotating spindles and production is started. A knife carriage travels along the tubes and cuts the flat sealing rings to the desired length with either push-fit or circular knives, depending on the requirements. This cutting method is particularly impressive with its high cutting quality in combination with a high output.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

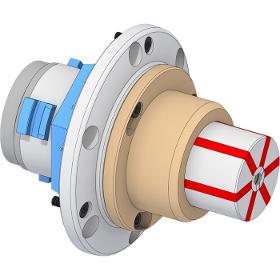

No problem to change-over from O.D. clamping to I.D. clamping Change-over from O.D. clamping to perfect I.D. clamping, without changing the clamping device? No problem with MANDO Adapt: Place the mandrel in the mounted clamping device, tighten three screws, and lock the mandrel in the clamping device. Reduce time In this process the mandrel engages in the coupling of the clamping device via a sophisticated mechanism, where otherwise the clamping head engages. MANDO Adapt is attractive with extreme rigidity and precision. Without adjusting For rotating products, concentricity of 0.005 mm between chuck taper and mandrel taper can be achieved. For stationary clamping devices repeatability of 0.003 mm is possible. And best of all: This can all be accomplished without adjusting.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

No problem to change-over from O.D. clamping to I.D. clamping Change-over from O.D. clamping to perfect I.D. clamping, without changing the clamping device? No problem with MANDO Adapt: Place the mandrel in the mounted clamping device, tighten three screws, and lock the mandrel in the clamping device. Reduce time In this process the mandrel engages in the coupling of the clamping device via a sophisticated mechanism, where otherwise the clamping head engages. MANDO Adapt is attractive with extreme rigidity and precision. Without adjusting For rotating products, concentricity of 0.005 mm between chuck taper and mandrel taper can be achieved. For stationary clamping devices repeatability of 0.003 mm is possible. And best of all: This can all be accomplished without adjusting.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

The segmented clamping bushing SE with the hexagon socket sits on the clamping pyramid, absolutely form-fitted in every clamping position and thereby enables maximum machining performance with minimal vibration and thus less tool wear. The full-surface contact of the segmented clamping bushing on the mandrel ensures a significantly better insensitivity to contamination than previous segmented clamping bushing/mandrel systems. Therefore, these segmented clamping bushings are even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. And they offer this suitability at run-out of ≤ 0.01 mm and in the premium version at ≤ 0.007 mm.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Depending on size, combined with all adaptations 5-axis machining or rational multiple clamping – with HYDROK we offer a hydraulically actuated stationary chuck that provides even more implementation possibilities. Depending on size – you can use it with all clamping device adaptations, such as the MANDO Adapt mandrel-in-clamping device or with the jaw module. Thus in the future you can also rely completely on the intelligent HAINBUCH modular system, even for your stationary clamping device. Multiple clamping in confined spaces The smallest of the group: HYDROK 40 SE and 32 RD. Their modular base plates can be easily fitted together and enables multiple clamping with incredible holding forces in the most confined spaces. And with an additional tandem cylinder you can even generate the full clamping force with a weaker hydraulic unit.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Made for the gear-cutting sector Clamping solutions for the gear-cutting sector are individual and have very special requirements. Consequently, it is not easy to find the suitable clamping device, particularly in the case of high variant diversity and smaller lot sizes. The conventional solution is to use fixtures that are more or less effective. Rigid and narrow standard segmented mandrel Fortunately, this is now history. With the MANDO G211 you are relying on a standard segmented mandrel. You profit from in-stock segmented clamping bushings. The rigid and narrow mandrel with optimized tool runout contour is ideal for use in gear cutting applications. Moreover, it can also be used for gear shaping or grinding. Three end-stop levels that are placed with different proximity to the workpiece make it possible to use individual workpiece end-stops. Also a coolant connection ensures process reliability.

Request for a quoteResults for

Clamping mandrels - Import exportNumber of results

10 ProductsCountries

Company type