- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- carbide tooling

Results for

Carbide tooling - Import export

BIAX - SCHMID & WEZEL GMBH

Germany

This spindle is designed to be very compact, yet has enough power for light grinding and milling. Also available: splash guard and counterclockwise rotation. Technical Data: Order number: 150412702 Power [W]: 200 Air consumption [l/min]: 400 Vibrations [m/s²]: < 2,5 Revolutions per minute [min¯¹]: 32.000 Engine type: Vane Exhaust air direction: Backwards Front bearing set: Paired Noise level [db (A)]: 75 Weight [g]: 365 Max. tool shank Ø [mm]: 6 Max. carbide tool Ø [mm]: 8 Fitting hose unit: 001366529 (not inclusive)

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quote

STARRAG GMBH

Germany

s230 is an automatic solution for faceting and diamond finishing dials index. s230 production center allows the production of a wide variety on index in various metals. Contrasts of different visual effects are performed by the use of diamond tools or solid carbide tools. The complete solution for small and medium series for finishing index combines multiple operations on a single machine. Features Optical recognition and origin definition of blanks Diamond with the revolver toolholder Machining of LuniNova pockets and micromilling Simple programming interface on Windows A variety of automation systems are available to ensure a high level of autonomy in production

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Carbideline consists of CarbideLine-S solid carbide tools, CarbideLine-H hybrid tools and multi-part carbide tooling with CarbideLine-I indexable carbide tools. All CarbideLine tools excel through maximum productivity in their specific fields of application. CarbideLine-H tools are a new addition to the product range. They cover the module range 5 to 12 and are the 1st. choice for rough machining and finishing large lot sizes, where the tools costs using solid carbide milling cutters are too high and the gear cutting quality is too low using indexable inserts. CarbideLine-H tools are also highly suitable for machining high-strength materials up to 1,400 N/mm2 and enable a gear quality up to quality grade AAA. Its preferred area of application is for gears for commercial vehicles, general mechanical engineering and energy technology. In one specific application it was possible to reduce the gearing costs per wheel by 20% with the CarbideLine-H compared with an indexable insert system.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

With the DHC Premium solid carbide end mills, LMT Tools significantly increased the performance of the low-vibration premium tools: 25 % added machining volume is the result of different helix angles in connection with newly developed, stable front cutting edges and peripheral teeth. Additionally, the new cutting material LCPK30M including an innovative PVD high-performance coating contributes to an improved tool life and a safe chip removal. A special performance feature of the DHC Premium end mill (Different Helix Cutter) by LMT Fette consists in its multifunctionality: it allows the user to rough and finish with the same tool. It can also produce narrow projections and up to 2xd-deep slots in steel and cast materials with exceptional surface quality. Advantages: - Increase of the machining volume by 25 % - Increased process reliability due to stable cutting edges - Multifunctional – roughing and finishing with the same tool

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Zinner has a comprehensive programme of HSS and solid carbide boring tools for non-ferrous metals. The various systems enable the user to acquire the right boring tools for his application from a wide range of tools.

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Zinner has a comprehensive range of HSS and carbide boring tools. The extensive spectrum of tools in the Zinner boring system enables you to find the right boring tool for your special job. Features of the modular drill The positioning of the inserts is optimised for a balanced distribution of cutting forces. The generous chip space ensures efficient chip removal. The diameter range is from 16 mm - 58 mm. Reamers are designed to optimise work processes – boring and reaming in one process. Tool systems Twist drills in solid carbide and HSS for mild and stainless steels. Deep hole drills up to 30 x D in solid carbide. 3-lipped drills for grey cast iron and aluminium alloys. Modular drills for various coatings for particular machining situations. Solid carbide drills High speed steel drills (HSS) Exchangeable tip drills Solid carbide end mills Polycrystalline diamond drills (PCD drills) Modular drills Deep hole drills

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

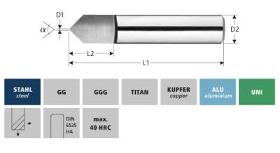

fine-grain solid carbide engraving tool

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

micrograin solid carbide dovetail milling tool: with double flute

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

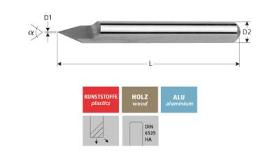

micrograin solid carbide engraving tool: with single flute, right-hand cutting, conic tool tip, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

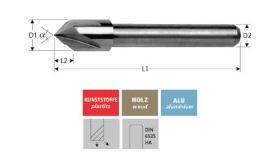

micrograin solid carbide countersink tool: with triple flute or four flutes, centre cut, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

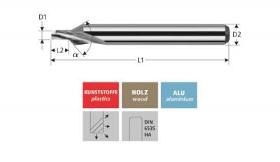

micrograin solid carbide milling countersink tool: with single flute, right-hand cutting, centre cut, shank without clamping surface DIN 6535-HA

Request for a quoteResults for

Carbide tooling - Import exportNumber of results

13 ProductsCountries

Company type