- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- brake fluids

Results for

Brake fluids - Import export

SCHWEIZER GMBH & CO. KG

Germany

Separate brake fluid reservoir for individual installation in the engine compartment.

Request for a quote

GOODRIDGE GMBH

Germany

Goodridge Racing Brake & Clutch fluid has been designed for all levels of race use, from grass roots to vehicles competing at the highest level; compatible with DOT 3 & 4 Car and Motorcycle brake systems. Dry boiling point: 312°C/593°F (Fresh fluid) Wet boiling point: 204°C/399°F (Used fluid) The Goodridge Race fluid is specifically formulated for use by racing teams operating at championship winning level, with a dry boiling point rated to that used in Formula One. Used in conjunction with Goodridge Premium Performance Brake and Clutch 600 series hose assemblies; Goodridge Racing Fluid offers race teams a high performing fluid for championship winning braking performance. Product certifications: - US FMVSS 116 DOT 4 - DOT 3 - SAE J 1703 - SAE J 1704 - ISO 4925(Classes 3 & 4)

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Special feed line for brake fluid. The supply line connects the brake fluid reservoir and the brake cylinder with one another.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

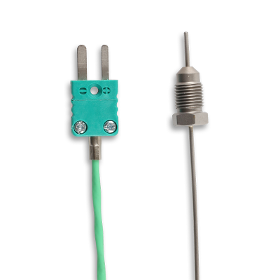

The braking fluid thermocouple from Therma convinces not only with its compact construction but also with its simple installation. Just screw it in in-place of the air vent screw to measure the temperature of the brake fluid. The subsequent sheathing line can then be comfortably bent in the required direction. When the thermocouple is screwed in, the braking system is then vented through its thread. The temperature measurement of the brake fluid, along with the brake disc surface measurement, also supplies important control values for a successful and safe race. During long races or races with many downhill routes, the brake disc overheats over-proportionally. The accruing radiation heat during this has a direct effect on the brake fluid, respectively heats it up. Depending on the type of brake fluid being used, it already reaches its boiling point at approx. 140–260 °C.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Degreasing all surfaces and parts of non-absorbent materials, e.g. metals, ceramic or plastics and elastomers Cleaning of adhesive surfaces for coatings, paints or adhesives and sealants Cleaning of friction surfaces on which high friction forces are transmitted such as clutch and brake linings (brake cleaners) Removal of aged and gummy oil and grease residues, of residues of brake fluids and silicones, as well as of residues of simple coatings, adhesives and sealants Advantages and benefits Highly effective due to actively cleaning substances Modern cleaner on a solvent base Fast and residue-free evaporation of the cleaner OKS 2660 is suitable for use with the OKS Airspray system Also available as spray version OKS 2661

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Degreasing all surfaces and parts of non-absorbent materials, e.g. metals, ceramic or plastics and elastomers Cleaning of adhesive surfaces for coatings, paints or adhesives and sealants Cleaning of friction surfaces on which high friction forces are transmitted such as clutch and brake linings (brake cleaners) Removal of aged and gummy oil and grease residues, of residues of brake fluids and silicones, as well as of residues of simple coatings, adhesives and sealants Advantages and benefits Modern active cleaner on the basis of a solvent mixture Highly effective due to actively cleaning substances Better initial dissolving of soiling than at brake cleaners thanks to longer soaking-in period No formation of condensate on the material surface OKS 2610 is suitable for use with the OKS Airspray system

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Degreasing all surfaces and parts of non-absorbent materials, e.g. metals, ceramic or plastics and elastomers Cleaning of adhesive surfaces for coatings, paints or adhesives and sealants Cleaning of friction surfaces on which high friction forces are transmitted such as clutch and brake linings (brake cleaners) Removal of aged and gummy oil and grease residues, of residues of brake fluids and silicones, as well as of residues of simple coatings, adhesives and sealants Advantages and benefits Modern active cleaner on the basis of a solvent mixture Highly effective due to actively cleaning substances Better initial dissolving of soiling than at brake cleaners thanks to longer soaking-in period No formation of condensate on the material surface OKS 2610 is suitable for use with the OKS Airspray system Also available as spray version OKS 2611 (propellant gas CO2)

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage. Types of Media The level monitoring sensors are designed for two different media types: For electrically conductive liquid media with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) For electrically non-conductive liquid media

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors react when a filling level is exceeded or falls below a limit. Aqueous mediums like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate. Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

PACA GMBH

Germany

The Paca Component Cleaner is a professional, fast cleaner. Versatile and effective, it is universally usable and largely biodegradable. It removes oil and grease, hardened residues and brake fluid. It degreases glued surfaces and sealing surfaces, cleans com- ponents efficiently and safely, dries quickly and leaves no residue. CO2 propellant AOX-free Fields of application The automotive industry, construction machinery, agricultural machinery, tools, sport, hobbies, home and garden, office Usage Check the rubber and plastic parts for compatibility beforehand, as Paca Component Cleaner may cause lacquers to corrode. Spray Paca Component Cleaner at close range onto the part which needs cleaning, repeating this step if there is excessive contamination. Allow the solution to dry, then wipe over with a clean cloth. Always shake Component Cleaner well before use! Batch quantity/Packaging units Batch quantity: 150ml and 500ml spray cans Packaging units: 24 150ml cans or 12 500ml...

Request for a quote

KERONA GMBH

Germany

5400 Brake Cleaner spray is particularly suitable for removing oily dirt. Cleaning is quick and easy thanks to the high evaporation rate and the concentrated spray. No residues remain after flashing off. For cleaning oil, grease, dirt, dust and brake fluid or resinized lubricants. Typical contaminants for use are e.g. Brakes, clutches, engine parts. As a rule, rubber and plastic parts are not attacked. The brake cleaner is not corrosive and acetone-free. Advantages – Quick and easy cleaning – Residue-free – compatible with materials Application fields Auto repair shops, Industry, Metalworking Container 500ml Spray can

Request for a quoteResults for

Brake fluids - Import exportNumber of results

14 ProductsCountries

Company type