- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bottling systems

Results for

Bottling systems - Import export

MES TRADE GMBH

Germany

Bpa Free Material 450 ml Liquid and Solid Food Area 200 ml Liquid and Solid Food Area 100 ml Solid Food Area Builtin Fork Spoon Gel Does Not Contain Toxic Substances Not Suitable for Microwave Oven, Oven and Dishwasher. To prevent possible liquid leaks, keep your product upright when there is liquid inside. Do not keep milk and easily perishable liquids inside the product for a long time. Keep your product away from impacts and do not drop it. Hand Wash Only.

Request for a quote

VKF RENZEL GMBH

Germany

Compared to conventional systems, the dynamic pusher system "Adjustable Tray" offers you the possibility of placing a wide variety of beverage bottles directly next to each other on a shelf. The width of the shelf dividers can be adjusted to 6 different widths. The "Adjustable Tray" bottle pusher system is thus used for small and large bottles, which are optimally conveyed to the first row of your shelf. Your customers look at an orderly shelf and take in your entire assortment without being disturbed. At the same time you save the time-consuming maintenance of the shelf order. The beverage bottles are removed in individual units and the quantity is determined individually by the customer. We offer the bottle pusher system for three different shelf depths. 406 mm, 457 mm or 508 mm. The matching fastening rail (22.0424.1) can be used for all shelf depths and enables simple and quick assembly of the "Adjustable Tray" bottle pusher system.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

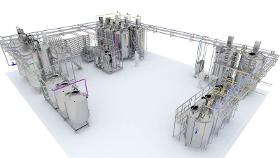

IFA Technology offers the complete range of conveying systems, storage systems and handling systems in mechanical engineering. Our plants and systems can be integrated into your own conveyor line or designed as completely automated systems. External plant components can also be integrated into our superordinate control system. Our plants and systems are mainly used for bagging or bottling or batch loading systems. Application of conveying, storage and handling systems: Dosing and application of liquids in the plant process Dosing and mixing of powders, fibres and liquids Bagging and bottling systems integrated into a production line Silo systems and tank systems with conveying paths and mixing systems Pipe shell plants

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers tailor-made plants and systems for the animal feed industry. Our mixing and dosing systems process both liquid and solid components, which are used for the production of animal feed, mineral feed and supplementary feed. To supplement our plant systems, we also offer adapted silo systems and tank systems as well as multifunctional filling systems and bagging or bottling systems for all types of containers. Our animal feed plants and systems are made of high-quality stainless steel and use food-grade materials and FDA-approved (Food and Drug Administration) components. Our focus is on hygiene and the diligence of the respective plant processes. The latest plant technologies guarantee the required degree of accuracy, economy and process reliability.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Labelling machine for wrap-around labelling Basic concept of the system for bottle labelling and can labelling: With the aid of the fully automatic VRM labeller, different cylindrical or square products can be labelled quickly and precisely on the circumference - wrap-around labelling. The machine is therefore used in many industries, from pharmaceuticals to food and cosmetics. The VRM series is suitable for bottle labelling, can labelling, vial labelling or for comparable containers such as jars or bottles. Several different formats can be covered simultaneously with one model. The VRM-DS labelling system includes a 3-roll turning station and is used for outputs of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the containers on the basis of a weld seam, print mark or other feature before labelling (target labelling).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CL MACHINERY GMBH

Germany

The VK138 bottle capper headset is Closure Systems International's tried-and-tested standard headset for aluminum roll-on closures. A customizable configuration of two flange and two thread rollers ensures optimum sealing efficiency. The head's slim construction makes it suitable for use even on small-pitch machines. Reliable & Simple Fast and simple control of side pressure using easy-access adjuster nuts Exactly coordinated leverages allow very small side pressure All bearings are fitted with replaceable bushings for easy replacement Two variable thread rollers and two adjustable flange rollers ensure uniform lateral forces, enabling the thread to be rolled out with maximized precision Tracer pin (safety plunger) prevents the roller arms engaging if there is no closure present Easily maintained with one lubrication point Maintenance-free ejector reduces stress, extending the maintenance intervals 100% stainless steel Versatility The centering bell to prevent skewed closures is.

CL MACHINERY GMBH

Germany

The VK900 bottle capper headset is Closure Systems International's tried-and-tested standard headset for aluminum roll-on closures. A customizable configuration of two flange and two thread rollers ensures optimum sealing efficiency. The head's slim construction makes it suitable for use even on small-pitch machines. Reliable & Simple Fast and simple control of side pressure using easy-access adjuster nuts Exactly coordinated leverages allow very small side pressure All bearings are fitted with replaceable bushings for easy replacement Two variable thread rollers and two adjustable flange rollers ensure uniform lateral forces, enabling the thread to be rolled out with maximized precision Tracer pin (safety plunger) prevents the roller arms engaging if there is no closure present NO LUBRICATION required. No grease point! Maintenance-free ejector reduces stress, extending the maintenance intervals 100% stainless steel Versatility The centering bell to prevent skewed closures is...

WHITE STEEL GMBH

Germany

DESCRIPTION the machine has been made with a compact design. Machine can handle multiple bottles type and size. Capping and closing star system (for compact design). Servo star system. Servo closing system. Bottles Sterilization system SPECIFICATION 2 Filling nozzles Servo conveyor system included Type of metal used S.S 316 for all product contact metal parts & S.S 304 for all uncontacted product parts HMI and Scada system. Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

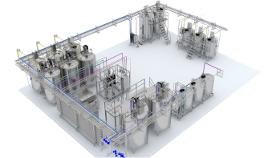

SPECIFICATION Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple product viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

1,Specification •,Milk Double jackets cooling collecting tanks •,Chillers. •,Storage feeding tank •,Processing section •,Cheese press to mold machines •,Mozzarella cheese making machines •,Vacuum cooker cream cheese making machines •,Rotary bottles washing system •,Milk, yogurt and cheese filling, sealing and capping machines •,Fermentation room. •,Compact design •,Available certification up on your request UL, CE, GMP, FDA, ASME. •,Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. 2,Description ,High stability on high capacity. ,Can handle multiple ointment viscosity and types ,Type of metal used S.S 316 / 304 ,Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. Our machine can handle a large type of vial bottles , types and shapes SPECIFICATION Machine is made up to the international GMP regulations Turn table feeding system Type of metal used S.S 316 Double Sterilizing nozzles system before and after filling. 2 diving filling nozzles 2 Peristaltic pumps Double star filling and capping system Double caps vibrator feeding system 1 Rubber vial stopper mushroom, 2 aluminum flip caps Rotary capping servo system Delaying bottles conveyor system Herma labeling head HMI and SCADA system with interactive touch screen control system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q , O.Q , P.Q, DQ.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

OPTIMUM11 GMBH

Germany

Lerasept® HR 1 liter euro bottle, skin-friendly with refatting system, bactericidal, fungicidal and viruscidal (corona viruses), 30 seconds exposure time, dosing function also without pump dispenser, euro bottle for disinfection dispenser, also available with pump dispenser (reusable).

Request for a quoteResults for

Bottling systems - Import exportNumber of results

15 ProductsCountries

Company type