- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- blowing

Results for

Blowing - Import export

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Continuous cleaning and blowing rotary system Hightech sensors HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Vertical blowing system. Servo conveyor system

Request for a quote

W. MÜLLER GMBH

Germany

Our extrusion heads for blow molding meet the highest demands in terms of precision, availability, performance and ease of use. And They ensure your safe and cost-efficient production.

Request for a quote

GSW SCHWABE AG

Germany

Cleanliness pays off over time. GSWNozzles prove this on a daily basis. Always exactly fitting the application, these components free any machine of burrs, oil and dust – quickly and with little noise.

Request for a quote

W. MÜLLER GMBH

Germany

The extremely space-saving design of our screen changer allows a lot of creative freedom, both with new machines and in the case of retrofitting, since the structure of the extruder platform only needs to be adjusted a little. The screen changer is installed instead of a connection piece and can be equipped with a hydraulic or electric drive. The simplest way, however, is to use a cordless screwdriver, which makes changing bits a quick and easy endeavor. Screen changers are available for all common throughputs.

Request for a quote

W. MÜLLER GMBH

Germany

The perfect combination of head and complete extrusion is the heart of every blow molding machine - tailor-made for your product and adaptable to every machine. Our platforms guarantee the greatest possible security and user-friendliness for users.

Request for a quote

W. MÜLLER GMBH

Germany

Even the best system needs a suitable controller. With our user-friendly and proven control concepts, you always have your production process in view and, above all, “under control” understandable, functional, reliable, clear and made for users. And Our wall thickness regulation saves raw materials and makes your production more sustainable!

Request for a quote

GSW SCHWABE AG

Germany

selfadherent blowout fitting through magnetic base amount of escaping air adjustable finely via a ball valve with position stable uniflextube for accurate positioning also suitable for cooling liquid

Request for a quote

GSW SCHWABE AG

Germany

ideal for producing an air curtain or for drying extensive areas high blowing power at significantly reduced noise development flexible in user applications

Request for a quote

GSW SCHWABE AG

Germany

high blowing power at significantly reduced consumption of compressed air and lower noise development for every case of use the right passage ideal for blowing out punch parts Heat Resistance 90° C

Request for a quote

GSW SCHWABE AG

Germany

the good value for money choice for all standard applications high blowing power at significantly lower noise development flexible in user applications low air consumption Heat Resistance 90° C

Request for a quote

KCD KUNSTSTOFFE, ADDITIVE UND BERATUNG GMBH

Germany

chemical blowing agents, microsphere masterbatches, lubricants, demoulding aids, UV stabilisation and more

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

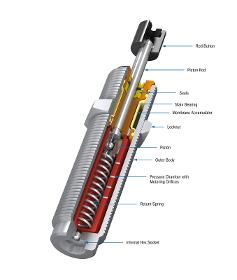

Energy capacity 56.5 Nm/cycle Stroke 18.7 mm Optimizing PET stretch blow machines: MAXIMACE, the new PET shock absorbers from ACE, shine with longer service life compared to previous solutions and an operating time of over 20 million strokes. They work simply and faster than other shock absorbers and are stronger at the same time. As a result, downtime is reduced and system performance and production volume are increased. This is accomplished by numerous details such as innovative aluminium outer housings for better heat dissipation, improved high temperature seals (up to approx. 107°C), a diaphragm accumulator for faster cycle times and a larger damper chamber which is filled with food-grade oil. All of this significantly contributes to reduced wear and extended service life. These self-adjusting, specialized shock absorbers stand out in their field of PET container production due to their compactness and distinctively colored aluminium bodies.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

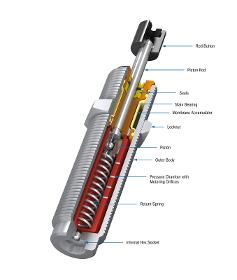

Energy capacity 56.5 Nm/cycle Stroke 18.8 mm Optimizing PET stretch blow machines: MAXIMACE, the new PET shock absorbers from ACE, shine with longer service life compared to previous solutions and an operating time of over 20 million strokes. They work simply and faster than other shock absorbers and are stronger at the same time. As a result, downtime is reduced and system performance and production volume are increased. This is accomplished by numerous details such as innovative aluminium outer housings for better heat dissipation, improved high temperature seals (up to approx. 107°C), a diaphragm accumulator for faster cycle times and a larger damper chamber which is filled with food-grade oil. All of this significantly contributes to reduced wear and extended service life. These self-adjusting, specialized shock absorbers stand out in their field of PET container production due to their compactness and distinctively colored aluminium bodies.

Request for a quote

KCD KUNSTSTOFFE, ADDITIVE UND BERATUNG GMBH

Germany

chemical blowing agents, microsphere masterbatches, lubricants, demoulding aids, UV stabilisation and more

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Blow-down, expansion and cooling module for cooling blow-down water to the permissible temperature — Fast and easy assembly, requires just a small number of connections before the Blow-down, expansion and cooling module can be used — Rigorous compliance with official requirements thanks to automatic operation

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the cooling of blow-down water and the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Rigorous compliance with official requirements thanks to automatic operation — Fast and easy assembly, requires just a small number of connections before it can be used

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Device for automatically blowing the adhering water off after passing through the pretreatment plant. The rotary blow-off zone is a device for blowing the adhesive water off workpieces that have been washed for the purposes of painting. It consists of a closed stainless steel sheet metal housing with forced ventilation and is employed immediately after the washing installation. In order to achieve more effective drying in the case of fissured surfaces, the blower nozzles are arranged on a rotary axis. The adhering water is blown off by the parts by air blown at high speed through the rotary blower nozzles. The effect of this is that no water droplets remain on the workpiece that could lead to slight marks in the paint film. Due to the varying blowing direction, the water is also blown out of problem zones and scooped parts in most cases. In order to be able to optimise the direction of the blower nozzle air jets, the nozzles have adjustable nozzle heads. The water that is blown off runs back into the pretreatment plant. The blowing air is extracted from the blowing tunnel via a return air duct with adjustable suction apertures.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Continuous rotary blowing machine 6 heads diving filling nozzles Star sterilizing capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

Electrostatics disturb almost all production processes. Eltex systems prevent uncontrolled discharges and integrate electrostatics precisely into your processes. In our electrostatic discharge product portfolio, you will discover systems and products for many industrial sectors. Compared to similar products, the ion blowing technology features longer ionization range as well as ionization performance that is many times higher. While the ion blower nozzles and the ion blower nozzle carrier are permanent installations, the ion blower pistols show their strengths in hand-operated use. All ion blowers discharge and remove dust from highly sensitive components. The emission tips enveloped by the airflow generate a discharge cloud enriched with ions.

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Touch-on applicator with blow function LA-TO Blow (for ALX 92x, ALX 73x, ALS 20x, ALS 256, ALS 272, ALS 306): • Suitable for labeling sensitive items with uneven surfaces and/or variable heights • The last part of stroke length is overcome by blowing the label onto the product • Stroke length up to 380 mm • Minimal wear means minimal maintenance

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Fränkische Industrial Pipes GmbH & Co. KG considers itself an international partner with the automotive industry, the home appliance industry and the machinery industry in developing technically complex corrugated tubes, corrugated tube systems, protective hoses and fluid transport conduit systems. Our custom blow molded parts for air ducts, clean air, recycled air are 3D blow molded and suction blow molded. They are 100 percent leak-proof and guarantee consistent wall thickness. They provide high stiffness combined with high mechanical strength and have been designed to match the different nominal sizes and inside diameters of our corrugated tubes with cuffs. Our corrugated tubes with integrated containers have been designed to reliably collect and store liquids without running the risk of leakage. The product can be custom-tailored in different nominal sizes, types of containers (with and without lid) and cuff sections to meet customers specifications.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Fränkische Industrial Pipes perceives itself as an international partner for developing technical sophisticated corrugated tubes, tubing systems and cable protection tubes as well as fluid systems for the automotive sector, household appliances, machine engineering and apparatus engineering and also for the industrial sector. In the field of agricultural and construction machinery, our offer includes blow-moulded parts made of plastic, drainage systems, fuel line systems, air intake systems, air guidance systems, windscreen cleaning systems and various types of tubes. The tubes and appliances are occasionally being exposed to strains and ambient conditions. That is why FIP sets a high value on product quality for their customized tubing systems.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp Bond Analyzer BLOW-SCAN is a detection systems which automatically detect blows and unbonded areas during the production of wood panels. It utilizes ultrasound and therefore is suitable for harsh production environment. Self-Calibration takes place in each panel gap. This compensates inuences raised from waste deposits and temperature variations. The models CONTI-SOUND and BLOW-SCAN are preferably installed in particleboard, MDF and OSB production lines. Changes of the panel properties are shown so the measurement can be used as an early warning System Features and Function Board thickness < 60 mm Density > 550 kg/m3 Detectable blow size > 28 mm Online calibration Automatic adjustment of sensor sensitivity Automatic recognition and compensation of dust load on sensors Automatic compensation of temperature drift Real-time data analysis Remote service

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our ducts and corrugated tubes for engine air intake can feature flexible sections, smooth sections and matching connections to meet customers specifications. This is a reliable way to connect a corrugated tube to the connecting cuff and allows for time-saving assembly. The advantages are obvious: Weight can be reduced, and great flexibility with high flow quantity and high strength in the cuff section are guaranteed. Available materials/maximum operating temperature: PP 100°C PA6 120°C PA12 120°C Application: Automotive, agricultural machinery and construction engines, in applications that require small bend radii and/or dynamic stress environments, connecting lines between various components, engine air intake

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our custom blow molded parts such as containers, air conduction tubes, connection tubes and drainage tubes are 3D blow molded, suction blow molded and manipulated by a robot (3-D Roboter Blow Moulding Machine). They are 100 percent leak-proof and guarantee consistent wall thickness. Since the blow molds are developed by and tailored to customer specific requirements, a perfect fit is guaranteed, the number of assembly steps is reduced, weight is reduced and the risk of leakage is minimized. Available materials / maximum operating temperature: PE / -40°C up to + 70°C PP / -40°C up to +105°C Dimensions: max: 900x500x300mm min: 50x20x100mm eight/pc.: 10-3.000 Gramm diameter: min. 8-10 mm Application: Industrial applications, such as home appliances, air conditioning, medical technology, etc.

Request for a quoteResults for

Blowing - Import exportNumber of results

35 ProductsCountries

Company type

Category

- Machine tools, metal shaping - parts and accessories (5)

- Cables - accessories (4)

- Electric motors and parts (4)

- Hoses, pipes and tubes - plastic (4)

- Additives for plastics industry (2)

- Boilers, industrial (2)

- Electronic components (2)

- Food industry - machinery and equipment (2)

- Labelling machines (2)

- Ionisation equipment - air (1)

- Valves for industrial fittings (1)

- Coupling, pneumatic (1)

- Wood veneer - machinery and equipment (1)