- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- blades

Results for

Blades - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

Sharpener KSG processes the blades gently with short setup times thanks to its intelligent sharpening technology. The sharpening unit is positioned via a visor. Sharpener KSG guarantees rapid, reproducible sharpening and has a long service life thanks to the sharpening disks which are not actively driven. A counter is integrated for individual specification of sharpening cycles. Advantages Long service life thanks to non-actively driven sharpening discs Sharpening unit positioning via sighting tool Gentle processing due to clever sharpening technology Quick, reproducible sharpening Counter for the individual specification of sharpening cycles Short set-up times Simple operation Clear, robust technology

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Every Weber slicer contains a Weber blade. The involute or circular blades are manufactured in Weber's own blade factory in Mecklenburg-Lower Pomerania and marketed worldwide under the Durablade brand. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, slicing quality, resilience and durability. Durablade blades are now also available to fit other manufacturers' slicers. Price advantage thanks to new manufacturing technology We are continuously investing in research, progress and manufacturing technology. We recently supplemented our blade production with a robot-controlled and high-performance production system, which combines quality assurance with maximum profitability. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, cut quality, resilience, durability and reduced prices.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

One for many purposes: Powerful skinning machine for large and small cuts of beef, veal, pork, turkey, horse and game. The Skinner AMS 533 offers an ideal cutting width for processing large cuts, such as beef topside. Advantages Powerful for the highest yield from the smallest installation area Product-specific optional transport rollers and speciallycoordinated blades provide the highest possible yield Ideal cutting width for powerful skinning of large and small cuts Blade guard in cleaning position Gear brake motor with quick stop Product-specific tension rollers Newly-developed compressed air transport roller cleaning,resulting in consistent skinning results Options: Body lever switch Quick release lock for tool-free blade changes Special rollers Skinning procedure protection Special tension rollers

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Weber Slicer 804 is among the most efficient systems in its class. The involute blade system cuts products up to 1,700 mm in length at a maximum speed of 2,000 slices per minute. The automatic central operation ensures quick product changes. Slicer 804 uses a blade head with an idle cut function, which positions slice thicknesses between 0.1 millimetres and 50 millimetres precisely in various presentation forms. The 400 mm wide and 180 mm high product throat permits four 90 calibre products or three 100 x 100 products to be processed simultaneously. The system includes a programme-controlled, automatically configurable product clearance height and width. Weber Hygiene Design ensures that the system is easy to clean. Options: Slice folder Variogripper Idle cut blade head

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer 905 combines innovative slicing technology with versatility, efficiency and ease of operation. The extremely wide cutting throat and blade speeds of up to 2000 rpm allows the industry’s highest throughputs. The improved product control system provides perfect slicing results. Delicate and odd shaped products are easily loaded and sliced. The open frame design of the 905 allows easy access for operation, maintenance, and cleaning functions. The product control system has been upgraded to allow for more hygienic operation and quicker disassembly for cleaning. The Weber 905 has been designed and constructed to meet the world’s highest sanitation standards. The modular design allows the Weber 905 to be used in conjunction with all Weber up and down stream accessories such as stacking, party tray, automatic infeeding unit, etc.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer weSLICE 9500 is the new high-performance machine in the slicer portfolio, which once again set the standard with regards to quality and performance. On the one hand, the uncompromising slicing quality and performance is achieved using the new Weber DirectDrive technology. The product is precisely guided by the direct drive of all components, so that in addition to perfectly sliced, visually appealing slices, the highest portion weight accuracy is achieved while at the same time providing maximum protection for the product. On the other hand, equipment highlights such as the Weber Durablade Performance involute blade ensures the best slicing quality. Moreover, the Vario technology of the new slicer-flagship weSLICE 9500 contributes to this unique performance. If Weber vacuum gripper technology is used, the product yield is increased even further, as remaining end pieces are reduced by more than half.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

For gravure, flexo and offset printing, with a wide variety of working edges, made from a wide variety of materials. We always have the material in stock for the most common chamber doctor blade systems.

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

Washing squeegee with rubber lip for all common printing machines and inks.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

The high noise level at a construction site can damage the health of construction workers and others. Residents near a building site are often suffer for weeks and months due to noise emissions. Since in most cases it is not possible to protect the whole work area of the building site against noise emissions, it must be attempted to make the individual construction machines and devices less noisy. For equipping circular building site saws, AVOLA has developed a special blade-type HM/A/SG = carbide tipping/wolf tooth/silenced. This saw blade has eight serpentine laser incisions in the master blade 8 that reduce drumming of the master blade. At the same time, these laser incisions are distributed in such a way that the master blade still retains the pretension that is needed for the stability of the saw blade when idling and cutting.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA Circular saw blade HM/A/PH for cutting polystyrene and wood Special benefits of our patented development: One saw blade for two materials For polystyrene (Styrodur and styrofoam) and wood No jamming and sticking, because the newly developed openings in the master blade ensure sufficient air cooling Even without blade replacement More safety and occupational protection Faster, more effective and environmentally friendly operation

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

State of the art machines, tightest tolerances Machine knives for use in steel production are challenging from a production engineering point of view and place enormous demands on quality. A knife change always entails a long and thus costly system shutdown; consequently, long knives and circular knives from our company are characterised not only by very high accuracy, but also by their extreme resistance to wear. In the past, we have made serious investments in our machine fleet, in order also to produce to the most complicated geometries and tightest tolerances. In addition to standard qualities, we also deliver special qualities for particular stress at high temperatures.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

This how each cut is made Sheet metal is available in a very wide range of materials and alloys. The criterion for machining is a given toughness and strength to make the metal sheets deformable. A part of sheet metal machining is separation by shearing, in which the sheets are divided by two shearing knives. For over 40 years, we have supplied shearing knives in lengths up to 4,190 mm in qualities and hardnesses specially matched to the purpose for the corresponding machines. By using peripheral grinding machines, we can comply with the tightest form and position tolerances, which is why so many machine manufacturers rely on the quality of our shearing knives.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Trimmed for peak performance The construction industry is booming – and this has been the case for decades and all across the world. The need for new buildings, bridges and general infrastructure is constantly increasing. In terms of modern urban development, the demolition of buildings that are no longer up to date is part of everyday life. The stress on the tools used for this is easy to imagine. Demolition shears are used, for example, to cut angle iron or wire mesh, or to cut concrete ribs and steel rods. Our shearing knives or shear blades for mobile demolition shears are designed exactly for these massive stresses and have been used for many years on construction sites all over the world.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Market leader with OEM quality In principle, metals can be melted on numerous occasions and reworked. This is, therefore, conventional recycling, , as a new product with similar properties and of identical quality comes from a starter material. In addition to hammer axes, the scrap shearing knives used in this industry are in our product range. Since the beginning of scrap recycling, our clients have relied on our highly accurate and extremely robust shearing knives and, even today, we are, with our 100 years of experience, a market leader in this sector. You find our Webshop https//shop.buchholzgruppe.eu/shop We also supply you the necessary machine parts (knife seat and knife holder) for the overhaul of your shear.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Market leader with OEM quality In principle, metals can be melted on numerous occasions and reworked. This is, therefore, conventional recycling, , as a new product with similar properties and of identical quality comes from a starter material. In addition to hammer axes, the scrap shearing knives used in this industry are in our product range. Since the beginning of scrap recycling, our clients have relied on our highly accurate and extremely robust shearing knives and, even today, we are, with our 100 years of experience, a market leader in this sector. You find our Webshop https//shop.buchholzgruppe.eu/shop/

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IDG-DICHTUNGSTECHNIK GMBH

Germany

Kaplan turbines are typically used for river power plants on calm waters. The blade angle runner blades (Kaplan blades) is adjustable. The pressure of the water flow, which is controlled by the guide vanes of the upstream wicker gate, can then be efficiently converted into energy. The bidirectional MANOY® system seal WP, type 444, in the form of a continuous ring was developed to protect the hydraulic adjustment device and prevent hydraulic fluid leakage. Type 449 is particularly useful for maintenance work because rather than being continuous in circumference, the seal is open and has a guide blade.

Request for a quote

WESPA METALLSÄGENFABRIK SIMONDS INDUSTRIES GMBH

Germany

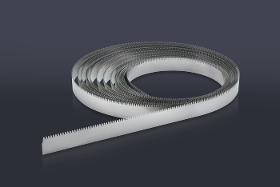

Bi-Metal Bandsaw Blade

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

For punching film or plastic packaging, manufactured according to customer requirements

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

In all common dimensions. For the production of paper carrier bags.

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

Whether cutting, sawing or perforating tooth, for all printing machines and grammages. Manufactured from conventional steel strips to high-alloy and powder metallurgical steels.

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

Knives for plastic and paper packaging

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

Special knives for beverage and filling machines

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

Fold and counter flaps with Metko or Vulkollan coating

Request for a quote

BIZERBA SE & CO. KG

Germany

Flexible sawing system for industrial food production The FK 32 is made entirely from stainless steel and with top quality construction all round. Depending on production environment and food to be processed this saw is available with a variable work area or can be mobile. Ergonomic and effective comminution and portioning of fresh and frozen foods. Area of Use Suitable for fresh fish as well as for frozen meat Products with bones such as shanks / osso buco and soup bones Production of same weight portions such as cutlets Due to its design and numerous variants it is the perfect tool for industrial use

Request for a quote

BIZERBA SE & CO. KG

Germany

The FK 23 is made entirely from stainless steel and with top quality construction all round. Ergonomic and effective comminution and portioning of fresh and frozen foods. Suitable for fresh fish as well as for frozen meat Products with bones such as shanks / osso buco and soup bones Production of same weight portions such as cutlets Due to the wide range of saw blades high quality products such as fine fish or matured beef can be processed by accurate weight and optically appealing

Request for a quote

BIZERBA SE & CO. KG

Germany

The VS12 W stands out due to its wealth of variants. Individual and powerful slicer for a variety of products to be sliced in manual mode. The vertical carriage ensures ergonomic, upright operation while providing an optimal view of the slicing result. The core component is a powerful blade drive, optionally with intelligent motor control Emotion®. In addition, the VS12 W can be fitted with Ceraclean® surface which is easy to clean and ensures easy feeding of products to the blade. Workflows for target weight slicing of up to 3 kg / 2 g are more efficient and precise due to a fully integrated portion scale.

Request for a quote

WESPA METALLSÄGENFABRIK SIMONDS INDUSTRIES GMBH

Germany

Metal Bandsaw Blades all products

Request for a quoteResults for

Blades - Import exportNumber of results

105 ProductsCountries

- Germany (105)

- Bonn, Düsseldorf and North Rhine and Westphalia (51)

- Bremen and region (3)

- Frankfurt am Main and Hesse (19)

- Hannover and Lower Saxony (2)

- Kiel and Schleswig-Holstein (1)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (11)

- Munich, Nuremberg and Bavaria (9)

- Stuttgart, Freiburg and Baden-Wurtemberg (8)

Company type

Category

- Blades for saws and cutting machines (26)

- Blades, circular (21)

- Hand tools, non-power (19)

- Blades and knives, industrial (12)

- Food Industry - Machines & Equipment (9)

- Steels and metals - forming and cutting (9)

- Components and parts for small household appliances (8)

- Sawing machine tools (5)

- Meat processing machines (3)

- Cheese (2)

- Gas and oil - exploitation (2)

- Meats, butchery and delicatessen - machinery and equipment (2)

- Sawmills - machinery and equipment (1)

- Food Processing (1)

- Ventilators and fans - industrial (1)

- 3D scanner (1)

- Building hand tools, non-power (1)

- Concrete forms (1)

- Gas turbines (1)

- Ham-slicers for butchers and delicatessens (1)