- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automotive interiors

Results for

Automotive interiors - Import export

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HMV is the preferred flame chamber for conducting burn rate and burn resistance tests on automotive interior materials. Its durable stainless steel construction, large glass viewing window, door- mounted burner and lift-off top cover for easy specimen access greatly enhance user convenience. The loading of specimens is simplified with a unique snap-together specimen holder. The optional Automatic Gas Control (AGC) features a digital timer and push-button gas controls that provide automatic or manual flame impingement modes. The Atlas HMV was designed with the user in mind. Worldwide use for qualification of automotive interior materials Stainless steel chamber with removable top Door-mounted burner with flame height adjustment and pilot ignition Stainless steel U-shaped specimen holder with support stand Specimen supporting wire Stopwatch and measurement scale Separate enclosure for gas controls Specimen holder assembly Stainless steel cabinet Specimen support frame Dimensions: 38cm (15'') W x 20cm (8'') D x 38cm (15'') H Weight: 11 kg (28 lbs.) Automatic Gas Control (AGC) System for automated flame impingement and piloted ignition

GRONBACH

Germany

Gronbach manufactures decorative elements for the automotive industry in interior and exterior areas such as trim strips or trim parts made of aluminium, stainless steel and plastic hybrid technology. Functional components and plastic injection molded parts with a focus on fan wheels and turbines are also essential components of our technologies. As a specialist for surface finishing, you have a wide range of colours (anodising, powder coating), noble shapes and surfaces (brushing, grinding, polishing, blasting) and high-quality individualisation (screen printing, pad printing, under-anodising printing, laser engraving, etching techniques) at your disposal. In addition to the production of individual parts and the manufacture of complex assemblies as well as end products, we also offer you as a system supplier the complete project planning for new developments. Our portfolio includes: Automotive door sills Interior visible parts, e.g. side applications, decorative panels and...

Request for a quote

FRIMO GROUP GMBH

Germany

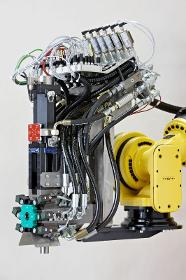

FRIMO PURe Mix mix heads are available as two-component or multiple-component mix heads for various PU product manufacturing. Different sizes for the smallest and the largest output rates are available. FRIMO offers a patented PU spraying system for the production of high quality PU surfaces, such as for automotive interiors.

Request for a quote

FRIMO GROUP GMBH

Germany

Form and appearance ideas first become tangible through the help of models. We produce models for all stages of the design and development processes, from the smallest models up to cubing models (e.g. complete automotive interiors). All products are customized and can be designed according to customer requirements .

Request for a quote

FRIMO GROUP GMBH

Germany

Leading the market Leather laminating is found mainly in the automotive industry. High quality vehicle interiors are characterized by a sophisticated design made of perfectly processed and adapted materials. Leather surfaces are no longer exclusively reserved for premium vehicles; they are also becoming increasingly used in high volume and mid-priced vehicle interiors. As a natural material, leather presents tough processing challenges. Variations, quality/quantity requirements and numerous project-specific parameters demand smart manufacturing solutions that can only be produced with extensive experience and in-depth technology and process expertise. FRIMO's tooling and equipment technology in leather processing leads the market. Along with leather laminating come leather back-foaming and leather scoring for hidden airbags.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HEXPOL TPE GMBH

Germany

We are successfully helping to convert a rapidly growing plastics waste stream into new life plastic products with our Dryflex TPE compounds based on Post Consumer Waste. The thermoplastic elastomer materials were developed to address demands in the automotive industry, which is obliged to use increasing quantities of post consumer waste and operate under the EU ELV Directive to ensure recyclability at the end of each vehicle’s life. The materials contain a high volume of post consumer waste from 33% to 80% by weight. Recyclate consists of polypropylene drawn from automotive mouldings, which are cleaned and re-ground and rubber tyre crumb from both OEM and after market tyres. Apart from the obvious benefit of recycling, the material exhibits other advantages when compared with virgin materials particularly its superior Ultra Violet, and weathering resistance and sound reduction properties. Applications Automotive interior & exterior trim Mudflaps Underbody stonechip protectors An

Request for a quoteResults for

Automotive interiors - Import exportNumber of results

7 ProductsCountries

Company type