- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic packaging machine

Results for

Automatic packaging machine - Import export

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Our fully automatic flowpack machines are suitable either for high-speed applications or airtight film packaging requirements as well as for paper packaging, depending on the version selected. The machines feature either rotating or box motion transversal sealing units, with selection of a longitudinal seam either above or below. Each machine can be combined with a wide range of feed systems, such as finger conveyor chains or infeed belts. With our ability to handle everything from PP or aluminium laminated films through to Tyvek® – anything is possible. Coated paper can also be used for flowpack production. Our flowpack machines are also available as hygienically designed versions.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

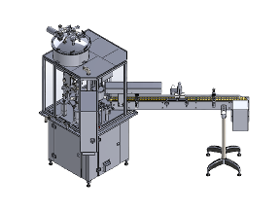

A full automatic packaging machine that fills in plastic containers and thermally welds them. It consists of five work stages that start with pulling the empty containers, then packing, then coverings, then welding and taking out. Suitable for medium products, with a production capacity of 1500 packages per hour.

Request for a quote

GEBR. DÜRRBECK KUNSTSTOFFE GMBH

Germany

Centrefold plastic film is created by slitting blown film, which is closed on both sides, at the side or down the centre, as desired. It is basically folded flat film. Centrefold film can be used for a wide variety of packaging solutions. One good example is in the furniture industry, which uses centrefold film as furniture covers to protect pieces from dirt and dust. But centrefold film also plays a major role in product packaging in other areas such as e-commerce, the pharmaceutical industry and the textile industry. Centrefold film is mostly processed using machines – especially L sealers, for example. Centrefold film is one of the most common types of plastic film used in automatic packaging machines.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication wherever good penetration capacity is the only possibility for relubrication, for example at joints, hinges, linkages, levers and guides Lubrication of machine elements subjected to moisture, for example at conveying systems, packaging machines, automatic filling machines, etc. Chains in a dusty environment Advantages and benefits Light-coloured High lubrication effect due to optimum product formula Good creep properties, thus easy penetration even in narrow, hard-to-reach lubricating points Good lubricating and pressure absorption capacity Excellent corrosion protection Good wear protection, also in comparison to higher-viscosity oils without solid lubricants Broad range of uses in all maintenance sectors Also available as spray version OKS 671

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

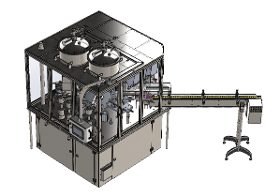

An automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five work stages that start with pulling the empty containers, then filling them, then placing the covers, then welding and taking out through the conveyor belt. It is suitable for high and medium production with a productivity of 3000 packages per hour.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication wherever good penetration capacity is the only possibility for relubrication, for example at joints, hinges, linkages, levers and guides Lubrication of machine elements subjected to moisture, for example at conveying systems, packaging machines, automatic filling machines, etc. Chains in a dusty environment Advantages and benefits Light-coloured High lubrication effect due to optimum product formula Good creep properties, thus easy penetration even in narrow, hard-to-reach lubricating points Good lubricating and pressure absorption capacity Excellent corrosion protection Good wear protection, also in comparison to higher-viscosity oils without solid lubricants Broad range of uses in all maintenance sectors

Request for a quote

PEKU FOLIEN GMBH

Germany

Zipperbags are almost airtight, frequently reusable and withstand heavy loads. Therefore, zipperbags are ideal for long term use. Our pressure lock bags or zipperbags are easy to open and to re-close and protect the content from contamination or loss. They are suitable for packing all sort of goods, e.g. small components for technical or household devices, as well as foodstuff or cosmetics. Transparent, reclosable zipperbags are also used in security areas of airports. If hanging storage is required, the zipperbags are available with euroslots. To ensure safety and integrity of the content, a tear perforation can be integrated in the bag. Zipperbags can be filled manually as well as automatically. Therefore, all zipperbags are available as wicketed bags, for automatic or semi-automatic packaging on your machines. Like all our packaging solutions, our zipperbags are available in nearly every quantity

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Manual feeding system , automated feeding system is also available up to your request Drum blender with paddles and gravity positioning flow system Fast and automated powder storage release system . HMI, PLC with SCADA system integrated for easy workflow Tunnel conveyor transfer system for quick and easy powder transfer Automatic weighing tower Electropneumatic Automatic weighing cells Vertical powder packaging machine Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

MOSCA GMBH

Germany

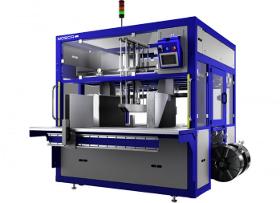

• SoniXs Utrasonic sealing unit in standard-6 version • High availability due to controlled frame • 5-sided electromechanical package alignment • Continuously adjustable conveyor speed • Laterally driven transport belts • Driven top belts • Electro-mechanical package stop and hold-down device • Intuitive user guidance via colored touch panel with ergonomic positioning options • ATR – Automatic cycle rate regulation • Easy maintenance due to automatic removable strapping unit • Automatic machine adaptation to package dimensions via adjustable recipes • CE marking inclusive conformity declaration

Request for a quote

MOSCA GMBH

Germany

• Inline strapping parallel to flute • SoniXs Ultrasonic needle sealing unit • Automated setup system resets to the dimensions of the first bundle of the new size [Teach-In] • 6-sided electromechanical package alignment • Potential-free contacts to upstream and downstream machines • Siemens PLC control with touch panel • Stand-by-mode reduces wear and energy consumption • Lateral automatic adjustment device • Automatic machine adaptation to package dimensions via adjustable recipes [500] • Sealing unit removing device

Request for a quote

DSMART GMBH

Germany

Production Process of laminated printed film roll A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of laminated printed film roll A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quote

DSMART GMBH

Germany

Production Process of automatic packaging film A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of automatic packaging film A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quoteResults for

Automatic packaging machine - Import exportNumber of results

13 ProductsCountries

Company type