- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automater

Results for

Automater - Import export

EWM AG

Germany

Fully automatic welding helmet with extra bright view in light state (shade level 2.5) — Exact compliance of the set shade level thanks to digital auto darkening filter — Higher safety and relief to the eyes thanks to shade level 2.5 in light state — Optional: Comfort lining to add to the headband — With true colour filter for a true colour view — Never before seen realistic colour perception thanks to new sensor technology — Adjustable arc recognition angle by means of sensor slider — Infinitely adjustable shade level control — Operating unit outside helmet — Grinding mode — Synergic or manual welding mode

Request for a quote

EM-TECHNIK GMBH

Germany

When operating pneumatic valves (diaphragm valves, etc.) special attention is placed on the protection of the control air system. The 5A compact safety valve reliably protects the control air system against media flowing back in case of leaks. The valve is automatic and therefore provides safety in the application.

Request for a quote

A.B.C. WORLDWIDE GMBH

Germany

Disinfectant dispenser with automatic spraying system. with wooden mounting Sensor range 0-12 cm (infrared sensor) Battery life (type AA) 1000 hours (batteries not included) 1000ml filling quantity Quantity per spraying process 1.2 ml Including security key for filling

Request for a quote

A.B.C. WORLDWIDE GMBH

Germany

Automatic desinfectant dispenser For wall mounting Infrared auto-sensing 0-12 cm sensing range 25ms response time battery working time 1000h (battery not included) liquid capacity 1000ml spraying volume 1.2ml

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in valve.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used for precision machine parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used in machinery accessories,produce by automatic turning machines.Precision work is demanding,machining tolerance is between +/-0.02mm.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in precision machinery,after processing, local sandblasting is carried out.

Request for a quote

BORNEMANN GMBH

Germany

Automatically switching stamping presses are automatically advanced with an embossing stroke. Automatically switching are five points as a rule, the other points are switched manually.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

New construction patented DE 20 2010 006 420*height adjustment by hand or cordless drill: precise,secure, quick*mobile and network-independent operation*integrated safety clutch*stainless steel plates*shear resistant pattern*top plate with Ø 10 mm hole*slip-proof rubber feet*suitable 1/4" bit for cordless drill included in delivery

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

New construction patented DE 20 2010 006 420*height adjustment by hand or cordless drill: precise,secure, quick*mobile and network-independent operation*integrated safety clutch*stainless steel plates*shear resistant pattern*top plate with Ø 10 mm hole*slip-proof rubber feet*suitable 1/4" bit for cordless drill included in delivery

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

New construction patented DE 20 2010 006 420*height adjustment by hand or cordless drill: precise,secure, quick*mobile and network-independent operation*integrated safety clutch*stainless steel plates*shear resistant pattern*top plate with Ø 10 mm hole*slip-proof rubber feet*suitable 1/4" bit for cordless drill included in delivery

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

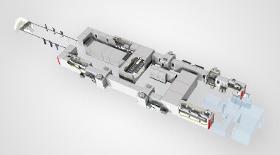

Our Speedmax is the fastest available wire and tube forming automation solution available on the market for bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax with its 90 servo axes can reach a speed of up to 4,000 machining steps per minute. The SPEEDMAX is available in three variants (S,M,L). The SPEEDMAX (S) has 20 processing stations and can produce up to 200 parts per minute. The machine concept combines the advantages of 3D-NC wire bending and wire bending by slides. Bending, embossing, notching, flattening, joining, punching, swaging of tubes and wire are possible production technologies in the 20 processing stations. The new SPEEDMAX L has actually 20 processing stations and can produce up to 60 parts per minute. The SPEEDMAX L can work with tube and wire up to a diameter of 12mm and a feed length of 50cm. Various bends in all levels and in the current equipment up to four swaging processes are possible.

Request for a quote

PRESSTA EISELE GMBH

Germany

Fully automatic operation cutting of aluminium and non-ferrous metal NC Control with touch screen display 5,7” Piece counter showing target/actual number of pieces Piece multiplier when cutting bundles Indication of cycle time Multiple feed device – max feed 3.250mm Table separation before the saw blade retracts so the profile is not touched by the saw blade Electronic material feeder, ball screw spindle and servo motor incl. pneumatic horizontal and vertical clamps Float mounting feeder to balance bend profiles Waste piece from 85mm Reducer of clamping pressure horizontal and vertical Cycle spray mist device with level indicator and automatic stop Cut-off length from 3mm Automatic cut-out when bar is finished Technical Data: Motor up to 18,5kW, S 6 40%, 400 V, 50 Hz, 2850 R.P.M. r.p.m. infinitely adjustable Saw blade speed 3.500 – 5.800 R.P.M Saw blade Ø 400mm Profile width max 200mm height max 120mm

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

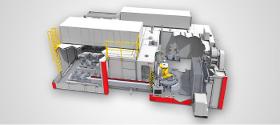

coating machine for large parts

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

coating system for high production quantities and individual transportation concepts

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

high performance coating of sophisticated parts

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

rotating spindle coating machine for larger quantities or longer process times

Request for a quote

SPIROL

Germany

SPIROL's Model CR Semi-Automatic Heavy Duty Pin Inserter is a robust, vertical pin insertion machine ideally suited for moderate to high production for applications requiring up to 8kN (1,800 lbs) of installation force. A retractable pin orientation head, mounted on a shaft/linear bearing arrangement moves up and down for ease of loading and unloading of the components to be assembled. The insertion bushing is positioned close to the part for smooth, trouble free installation. The orientation head shuttles the pin from the feeding position to the installation position, and also functions as a selector, preventing longer or shorter pins from being installed. A two position trap door allows for easy clear-out of the feed tube.

Request for a quote

SPIROL

Germany

This versatile installation machine is suited for moderate to high production applications requiring up to 1.3 kN (300 lbs.) of installation force. The pin insertion head advances and retracts for ease of loading and unloading of the components to be pinned. The machine’s insertion bushing is positioned close to the part for smooth installation. A vibratory feeder and orientation head transfers the pin from the feeder bowl to the installation position, eliminating the need for the operator to handle the pins. A quick-clear mechanism allows for easy clearing of the feed tube without the need for tools when changing pin size or performing maintenance.

Request for a quote

PRESSTA EISELE GMBH

Germany

High performance automatic circular saw for aluminum and non-ferrous metals Fully automatic operation Infinitely adjustable speed control of the saw blade engine Material and saw feeder movement through servo driven ball screw spindle 2 axis CNC control Siemens S7 with 7” touchscreen Cutting range: up to 205 mm height and up to 400 mm width Rest-piece length as short as 55 mm (depending on profile) Machine can use carbide (TCT) or PKD blades diameter 650 mm (smaller diameter upon request) Automatic kerf widening to reduce scratches Individually controllable clamping pressure Motorized material feed with servo driven ball screw Pneumatic material clamps individually adjustable Positioning of the vertical and horizontal clamps by hand-wheel Cut off lengths of up to 5000 mm are possible by reversing the material feed up to 5 times Floating material feed to reduce material abrasion Feeder length of 1000 mm Simple exchange of saw blade, accessible from the front Saw blade feed is...

Request for a quote

BÜRKLE GMBH

Germany

Burette with Schellbach stripes type Schilling / Bürkle with original Bürkle dosing armature. A universal aid in the laboratory, electroplating industry, water treatment plants, for field analyses, etc. Precise dosing using the press button, exact fine titration with the micro-screw and precise discharge jet. Graduation according to Category B (Tolerances according to DIN EN ISO 385).

Request for a quote

BIZERBA SE & CO. KG

Germany

Premium automatic vertical slicer Slicing without touching for maximum hygiene and optimal presentation The core component is a powerful blade drive with intelligent motor control Emotion®. Thanks to an automatic depositing system slices are laid out without manual handling and numerous depositing patterns allow optimal product presentation. The depositing system entirely made of stainless steel can be easily and quickly disassembled for thorough and efficient cleaning. The membrane keyboard with intuitive operating symbols ensures easy operation. Depositing patterns can be comfortably configured via direct keys and most frequently used keys can be permanently stored.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

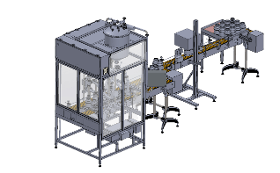

Challenger 200B is semi automatic linear system It’s designed for filling liquid or pasty products in plastic jar With five work stations: Adding jar on conveyor manually, filling, adding covers on jar manually, sealing cover (induction seal), Exiting.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

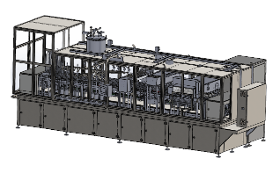

The 200A is linear filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines up to 24,000 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste and molasses in all size ranges.

Request for a quote

PRESSTA EISELE GMBH

Germany

Drive 7,5 kW, S 6, 400 V, 50 Hz, R.P.M. of sawblade infinitely adjustable (2.000 – 3.500 R.P.M.) Sawblade Ø 500mm, smaller blades on request Cutting range max. 215 x 120mm (height x width) Hydro pneumatic saw blade feed, Speed infinitely adjustable, linearly under the tabletop from rear to front Material fence on the table for the cutting angle Feed length limited via 4 end switch horizontal profile clamping device on the feed and discharge side Cycle spray mist device Pusher Profile feed from right to left with ball screw and servo motor Feed length from 10 to 2500 mm Feed speed max. 250 mm / sec. Repeatability +/- 0.1 mm iincl. horizontal pneumatic clamping device Reversing possible, max. Stroke length 7,300 mm Siemens S7-300 with touch screen 10“

Request for a quote

PRESSTA EISELE GMBH

Germany

Fully automatic operation Motor 7,5 KW, S6, 400V / 50 Hz, 2850 R.P.M. For the use of saw blade Ø 550 mm Big cutting range Max cutting height up to 150 mm Max cutting width up to 270 mm 90° cuts Remaining piece from 75 mm Table separation before sawblade retracts powered ball screw spindle material feeder up to 600mm Feed length up to 600mm, Multiple movement of the feeder possible up to 9,9 m

Request for a quote

PRESSTA EISELE GMBH

Germany

High-Performance automatic circular saw for aluminium and non-ferrous heavy metal Fully automatic operation Use of TCT or solid carbide blades ø 250 mm Motor 7,5KW, 400 V, 50 Hz, infinitely adjustable Blade feeder hydropneumatic Material feeder with ball screw spindle and servo motor 2-axis NC control Simatic S7-300 with 7“ touch screen Cutting range: height up to 60 mm, width up to 140 mm Manual safety cover 2x Ø 100 mm swarf extraction connector Blade feeder pneumatic hydraulic controled vertical top to down Manual blade feed adjustment to optimize the feed length Pneumatic clamps horizontal left and right of the blade Diagnosis of errors, trouble shooting Pneumatic clamps vertical left of the blade Mist spray blade lubrication (filling level controlled) 1 l tank Parts slide (Option: conveying belt) Material feeder from 2 – 650 mm with ball screw spindle and servo motor Multiple material feed possible up to 3250 mm cutting length Vertical and horizontal clamps Reducer of...

Request for a quote

SAMSYS GMBH

Germany

Unloading machine Multi-3000 remove The Multi-3000 remove is an electro-pneumatically controlled automatic unloading machine. It is the ideal complement to the bar feeder Multi 3000 or the Multi 3000SL. With the Multi 3000 remove it is possible to unload finished parts from sub- or main spindle. The bars are unloaded by unloading tube, pneumatic gripper or also by collet chuck. After unloading, the bars are placed on a prism. From the prism the parts are transported to a deposit. A light barrier monitors the unloading process. The coating of the depositing surfaces enables a particularly gentle handling of the finished parts. Even parts such as piston bars can be unloaded without a scratch. The unloading tube is made of POM material. This also ensures gentle handling. Loading can be done via the main spindle and unloading via the sub spindle. It is also possible to load via the sub spindle and unload via the main spindle. Compatible with almost all types of lathes.

Request for a quoteResults for

Automater - Import exportNumber of results

266 ProductsCountries

- Germany (266)

- Bonn, Düsseldorf and North Rhine and Westphalia (53)

- Bremen and region (2)

- Frankfurt am Main and Hesse (35)

- Hamburg and region (1)

- Hannover and Lower Saxony (26)

- Leipzig and Saxony (4)

- Magdeburg and Saxony-Anhalt (1)

- Mainz and Rheinland-Pfalz (21)

- Munich, Nuremberg and Bavaria (24)

- Potsdam and Brandenburg (4)

- Stuttgart, Freiburg and Baden-Wurtemberg (82)

- Weimar and Thuringia (13)

Company type

Category

- Labelling machines (26)

- Bottling and filling - machinery and equipment (22)

- Packing and packaging - machinery and equipment (19)

- Lubrication equipment and machinery (10)

- Metals - Machines & Equipment (9)

- Varnishing equipment (7)

- Wrapping machines (6)

- Metal straightening machines (6)

- Automation - systems and equipment (5)

- Water softeners (5)

- Automatic dispensers (4)

- Sawing machine tools (4)

- Measurement and control instruments (4)

- Food Industry - Machines & Equipment (4)

- Laboratory equipment and instruments (4)

- Meat processing machines (4)

- Electric transformers, converters and rectifiers (4)

- Machine tools - metal machining (4)

- Machine tools, metal machining - parts and accessories (4)

- Ham-slicers for butchers and delicatessens (3)