- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- assembly tools

Results for

Assembly tools - Import export

SCHWEIZER GMBH & CO. KG

Germany

Special aluminum tools to assemble aluminum fittings without damaging them.

Request for a quote

APEX TOOL GROUP GMBH

Germany

The Cleco® NeoTek™ fastening system is the next generation of smart tool solutions. The NeoTek 30 and 50 series tools have angle heads that were engineered to provide 1 million cycles maintenance-free, while delivering classleading repeatability of 2.0 Cm/Cmk at +/- 7%. NeoTek’s tool cable features an industryfirst quarter turn twist-lock design, thus eliminating one of the leading causes of tool cable failure: damaged threads. Cleco Neotek Right Angles are available from 1.3 to 350 NM, Pistols from 0.9 to 123 Nm and Inline from 0.9 to 850 Nm. - lightweight, ergonomic design - fully programmable features - high-output LED light rings - audible alerts - handle vibration - twist-lock design of the tool cable connector eliminates damaged threads - dual-analog and digital controller that supports legacy models - significant decrease of cable diameter and weight reduce by 50%

Request for a quote

APEX TOOL GROUP GMBH

Germany

Cleco's new CellCore™ Cordless Assembly Tools are smart, durable and designed to withstand the toughest environments. The lightweight ergonomic design reduces operator fatigue while delivering state-of-the-art power, weight and balance. A larger user interface makes it quick and easy to program rundowns on the tool without a controller. - Multi-Color LED for secondary okay/not okay visual feedback - Large User Interface allows easy on-the-tool programming without a controller - Exceptional Low Weight, Balance and Grip for superior ergonomics that increase productivity - Increased Storage - no uploading rundowns for up to one week (15.000 rundowns, 500 traces) - “Stay Alive” Function prevents reboot during battery change, gaining time and efficiency - Forward and backward compatibility with Cleco's entire Global Controller plattform

Request for a quote

IGUS® GMBH

Germany

Overview for triflex® advantages Other information triflex® RSP Continuously adjustable retraction force triflex® RSP triflex® RSE Infinitely adjustable retraction force for small robots triflex® RSE Triflex® R-Set Universal module for all motions on the robot Triflex® R-Set Fiber rod modules Intelligent problem solution through directed pretension. Fiber rod modules Universal assembly kit Offers the potential to mount the fiber rod module in the desired position on the robotic arm. Universal assembly kit Strain reliefs for large cross sections Secure mounting also in the use of cables with large cross section. Strain reliefs Gliding feed-through Available with and without swivel bearing Gliding feed-through Protectors Well protected in extreme applications. Protectors Heat shield Protection against weld and metal spills up to 600°C Heat shield CF Robot special cables Special cables for long service life in robotic applications. CF Robot special cables iF-Design Award for "TRC"- and "TRL"-Design Cleanroom environments on request Series TRC electrically conductive ESD/TEX versions possible UL94-V2classification Overview for triflex® advantages Other information Application examples Interesting applications from a variety of industrial sectors Triflex® R Configure interior separation Define cables, select chain and configure interior separation. Now also for all Triflex® R series! Internal separation configurator Triflex® R QuickRobot Equipment support for various types of robots. Simplified ordering of complete systems. QuickRobot TRC.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm Bending radius R: 50 mm Pitch: 11.3 mm e-chain® TRC.40 Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13,9 mm e-chain® Installation instructions Instructions for the joining and separating of the triflex® R - TRC. Assembly Instructions TRC.60 Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® TRC.70 Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain® TRC.85 Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRC.100 Inner height Bi 1: 37.5 mm Inner height Bi 2: 32.5 mm Bending radius R: 145 mm Pitch: 34.5 mm e-chain® TRC.125 Inner height Bi 1: 43,3 mm Inner height Bi 2: 43,3 mm Bending radius R: 182 mm Pitch: 44,6 mm e-chain® Standard mounting bracket for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRCF.85 Inner height Bi 1: 30 mm Bending radius R: 135 mm Pitch: 30.6 mm e-chain® TRCF.100 Inner height Bi 1: 37,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting bracket for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRE.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm Bending radius R: 50 mm Pitch: 11,3 mm e-chain® TRE.40 Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13,9 mm e-chain® Installation instructions Instructions for the joining, separating and filling of the triflex® R - TRE. Assembly Instructions TRE.60 Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® TRE.70 Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain®. TRE.85 Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRE.100 Inner height Bi 1: 37,5 mm Inner height Bi 2: 32,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® TRE.125 Inner height Bi 1: 43,3 mm Inner height Bi 2: 43,3 mm Bending radius R: 182 mm Pitch: 44,6 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRE.40.B Inner height Bi 1: 15 mm Inner height Bi 2: 13 mm Bending radius R: 58 mm Pitch: 13.9 mm e-chain® TRE.60.B Inner height Bi 1: 22,5 mm Inner height Bi 2: 19,5 mm Bending radius R: 87 mm Pitch: 20,4 mm e-chain® Assembly instruction Instructions for the joining, separating and filling of the Triflex® R - TRE-B version. Assembly instruction TRE.70.B Inner height Bi 1: 28 mm Inner height Bi 2: 24 mm Bending radius R: 110 mm Pitch: 25,6 mm e-chain® TRE.85.B Inner height Bi 1: 33 mm Inner height Bi 2: 28 mm Bending radius R: 135 mm Pitch: 30,6 mm e-chain® TRE.100.B Inner height Bi 1: 37,5 mm Inner height Bi 2: 32,5 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket Assembly tool triflex® R B-version Assembly tool for disassembly of triflex® R B-version Assembly tool triflex® R B-version TRL.30 Inner height Bi 1: 12 mm Inner height Bi 2: 10 mm bending radii R: 50 mm Pitch: 11,3 mm e-chain® TRL.40 Inner height Bi 1: 15 mm Bending radius R: 58 mm Pitch: 13.9 mm e-chain® Installation instructions Instructions for the joining, separating and filling of the Triflex® R - TRL. Assembly Instructions TRL.60 Inner height Bi 1: 23 mm. Bending radius R: 87 mm. Pitch: 20.4 mm e-chain® TRL.70 Inner height Bi 1: 28 mm Bending radius R: 110 mm Pitch: 25.6 mm e-chain® TRL.100 Inner height Bi 1: 38 mm Bending radius R: 145 mm Pitch: 34.5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket TRLF. 65 Inner height Bi 1: 24.4 mm Bending radius R: 100 mm Pitch: 23.1 mm e-chain® TRLF. 85 Inner height Bi 1: 32.8 mm Bending radius R: 135 mm Pitch: 31 mm e-chain® Assembly instruction Instructions for the joining, separating and filling of the Triflex® R - TRLF. Assembly instruction TRLF. 100 Inner height Bi 1: 38 mm Bending radius R: 145 mm Pitch: 34,5 mm e-chain® Standard mounting brackets for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection. Standard mounting brackets Light mounting bracket Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection. Light mounting bracket triflex® RSP Continuously adjustable retraction force triflex® RSP triflex® RSE Infinitely adjustable retraction force for small robots triflex® RSE Triflex® R-Set Universal module for all motions on the robot Triflex® R-Set Fiber rod modules Intelligent problem solution through directed pretension. Fiber rod modules Universal assembly kit Offers the potential to mount the fiber rod module in the desired position on the robotic arm. Universal assembly kit Strain reliefs for large cross sections Secure mounting also in the use of cables with large cross section. Strain reliefs Gliding feed-through Available with and without swivel bearing Gliding feed-through Protectors Well protected in extreme applications. Protectors Heat shield Protection against weld and metal spills up to 600°C Heat shield CF Robot special cables Special cables for long service life in robotic applications. CF Robot special cables This system is especially suited for: First choice for multi-axis industrial robots Three versions are available: TRC: closed design; TRE: "Easy" design, very easy to fill in from outside; and TRL: the "Light" version, likewise with "easy" design Universally applicable in general mechanical engineering Secure energy supply system Multi-axis (3D movements) High torsional stability Can be shortened and lengthened as required due to the individual elements Large filling space Doesn't get stuck in the interfering edges Small bending radius Simple cable routing for three-dimensional applications with ball-and-socket system for absorption of high tensile strength Cables easy to install and replace (TRE/TRL version) Fiber rod module for partial reinforcement and to give direction TRL - One-piece element, extremely light High tensile strength without additional elements like steel cables, spring elements, etc. Typical industrial sectors and applications First choice for industrial robots Machine tools Handling equipment 6-axis Material handling system General mechanical engineering iF-Design Award for "TRC"- and "TRL"-Design Cleanroom environments on request Series TRC electrically conductive ESD/TEX versions possible UL94-V2classification

Request for a quote

IGUS® GMBH

Germany

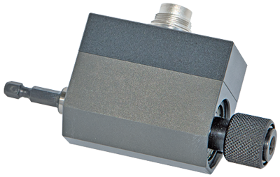

Other information Series 14040 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 14240 Inner height hi: 62 mm Inner widths Bi: 50 - 400 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Serie 14550 Inner height hi: 70 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 600 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 15050 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Serie 15250 Inner height hi: 86 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 14140 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 14340 Inner height hi: 62 mm Inner widths Bi: 50 - 400 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Serie 14650 Inner height hi: 70 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 600 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 15150 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Serie 15350 Inner height hi: 86 mm Inner widths Bi: 50 - 400 mm bending radii R: 150 - 600 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series R18840 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R19050 Inner height hi: 70 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 600 mm Pitch: 91 mm E-Tube, swivel lid Series R19850 Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 200 - 500 mm Pitch: 91 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series Special design Electrically conductive ESD/ATEX versions on request "Mounted on the side" unsupported application possible High torsionalstiffness Other information Series 14040 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 14240 Inner height hi: 62 mm Inner widths Bi: 50 - 400 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Serie 14550 Inner height hi: 70 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 600 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 15050 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Serie 15250 Inner height hi: 86 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 14140 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 14340 Inner height hi: 62 mm Inner widths Bi: 50 - 400 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Serie 14650 Inner height hi: 70 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 600 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 15150 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Serie 15350 Inner height hi: 86 mm Inner widths Bi: 50 - 400 mm bending radii R: 150 - 600 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series R18840 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R19050 Inner height hi: 70 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 600 mm Pitch: 91 mm E-Tube, swivel lid Series R19850 Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 200 - 500 mm Pitch: 91 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and opening of the E-Chain® and E-Tubes. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E4/light New E4/light version with the proved and tested "tongue and groove" system of the Series E4/4 Low weight Optimized interior-exterior dimensions ratio Cost efficient Manifold interior separation potentials Large accessory kits Thin external links Max. travel distance: 150 - 400 m Typical industrial sectors and applications Machine tools (closed E4/light tubes and open E-Chain®) Material processing Stone cutting machines Woodworking machines General mechanical engineering Vehicles Construction machinery Limited application of long travels Special design Electrically conductive ESD/ATEX versions on request "Mounted on the side" unsupported application possible High torsionalstiffness

Request for a quote

IGUS® GMBH

Germany

Other information Series 2828 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 3838 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 4040 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 2928 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 3938 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 4140 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 5150 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 4040HD Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 400 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050HD Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series R7728 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 100 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R7838 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R8840 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R9850 Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 200 - 1000 mm Pitch: 91 mm E-Tube, swivel lid Series R8840HD Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 400 mm Pitch: 91 mm E-Tube, swivel lid Series R9850HD Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series ATEX/ESD: Excellent match with special material igumid ESD (on request). "Mounted on the side" unsupported application possible High torsional stiffness System E4/4 proven in long travels Other information Series 2828 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 3838 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 4040 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 2928 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 3938 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 4140 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 5150 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 4040HD Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 400 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 5050HD Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series R7728 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 100 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R7838 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R8840 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R9850 Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 200 - 1000 mm Pitch: 91 mm E-Tube, swivel lid Series R8840HD Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 400 mm Pitch: 91 mm E-Tube, swivel lid Series R9850HD Inner height hi: 80 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and opening of the E-Chain® and E-Tubes. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E4/4 "Mounted on the side" - Travel distances over 200 m "Mounted on the side" - Travel distances over 200 m Extensive unsupported lengths for "side-mounted" applications Roller E-Chain® links available (with roller chain) Max. travel distance: 200 - 800 m High torsional stability Manifold interior separation potentials Large accessory kits Typical industrial sectors and applications RTG, quayside cranes, many other types of cranes Composting plants Gypsum, concrete, chemical and mineral plants, as well as agricultural plants Machine tools: unsupported, side-mounted applications Construction machinery ESD applications Heavy machinery Steel works Shipyards Welding plants ATEX/ESD: Excellent match with special material igumid ESD (on request). "Mounted on the side" unsupported application possible High torsional stiffness System E4/4 proven in long travels

Request for a quote

IGUS® GMBH

Germany

Other information Series 210 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm The E4.21 series is identical to 210 series and replaces it. E4.21 - E-Chain® with crossbars at every link Series 220 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series 280 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 380 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 400 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 600 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 640 Inner height hi: 112 mm Inner widths Bi: 87 - 562 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 290 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 390 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 410 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 601 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R760 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R770 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R780 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R880 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R608 Inner height hi: 108 mm Inner widths Bi: 200 - 500 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA certificate: Clean room ISO class 3 (DIN 14644-1) at v = 1 m/s for Series 280.10.100.0 tested ESD classification: Electrically conductive ESD/Atex versions on request Other information Series 210 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm The E4.21 series is identical to 210 series and replaces it. E4.21 - E-Chain® with crossbars at every link Series 220 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series 280 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 380 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 400 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 600 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 640 Inner height hi: 112 mm Inner widths Bi: 87 - 562 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 290 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 390 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 410 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 601 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R760 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R770 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R780 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R880 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R608 Inner height hi: 108 mm Inner widths Bi: 200 - 500 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and opening of the E-Chain® and E-Tubes. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. System E4/00 E4/00-E-Chain® with 4-piece structure The low-noise E4 chain Further noise reduction with sound dampers (E4/101 series) Wide application range Numerous interior separation options Large accessory kits Widths up to 2000 mm through extension links Snap-open along both sides Max. travel distance: Over 200 m Typical industrial sectors and applications Robotics and handling systems Materials-Handling Technology Refrigeration engineering Construction machinery Machine tools Wood working Any type of machines Semiconductor Clean room applications cold storage houses Welding machines Maritime applications General mechanical engineering etc. IPA certificate: Clean room ISO class 3 (DIN 14644-1) at v = 1 m/s for Series 280.10.100.0 tested ESD classification: Electrically conductive ESD/Atex versions on request

Request for a quote

IGUS® GMBH

Germany

Overview of E4.1 benefits Additional information Series E4.21 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm E-Chain® with crossbars at every link Series E4.28 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series E4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series E4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series E4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series E4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every link Series 1640 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 600 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.112 series Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.162 series Inner height hi: 162 mm Inner widths Bi: 200 - 600 mm bending radii R: 250 - 1000 mm Pitch: 200 mm E-Chain® with crossbars at every link Series 800 Inner height hi: 200 mm Inner widths Bi: 200 - 600 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series 840 Inner height hi: 204 mm Inner widths Bi: 100 - 563 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series E4.350 Inner height hi: 350 mm Inner widths Bi: 400 - 800 mm bending radii R: 500 - 1000 mm Pitch: 470 mm E-Chain® with crossbars at every link Series H4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series H4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series H4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series H4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every other link Series H4.112 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R4.28 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R4.56 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R4.80 Inner height hi: 80 mm Inner widths Bi: 150 - 460 mm bending radii R: 200 - 1000 mm Pitch: 111 mm E-Tube, swivel lid Series R1608 Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 600 mm Pitch: 143 mm E-Tube, swivel lid R4.112 series Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA classification -Report IG 1303-640, tested E4.32.10.063.0 41 dB(A) determined at the igus® laboratory, v = 1.8 m/s unsupported ESD classification: Electrically conductive ESD/Atex versions on request System E4.1 proven in long travels e-tubes available as special design with HT material for 850°C hot chips Overview of E4.1 benefits Additional information Series E4.21 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm E-Chain® with crossbars at every link Series E4.28 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series E4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series E4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series E4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series E4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every link Series 1640 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 600 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.112 series Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link E4.162 series Inner height hi: 162 mm Inner widths Bi: 200 - 600 mm bending radii R: 250 - 1000 mm Pitch: 200 mm E-Chain® with crossbars at every link Series 800 Inner height hi: 200 mm Inner widths Bi: 200 - 600 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series 840 Inner height hi: 204 mm Inner widths Bi: 100 - 563 mm bending radii R: 325 - 1000 mm Pitch: 250 mm E-Chain® with crossbars at every link Series E4.350 Inner height hi: 350 mm Inner widths Bi: 400 - 800 mm bending radii R: 500 - 1000 mm Pitch: 470 mm E-Chain® with crossbars at every link Series H4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series H4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series H4.56 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series H4.80 Inner height hi: 80 mm Inner widths Bi: 50 - 600 mm bending radii R: 150 - 1000 mm Pitch: 111 mm E-Chain® with crossbars at every other link Series H4.112 Inner height hi: 112 mm Inner widths Bi: 50 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R4.28 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R4.32 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R4.42 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R4.56 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R4.80 Inner height hi: 80 mm Inner widths Bi: 150 - 460 mm bending radii R: 200 - 1000 mm Pitch: 111 mm E-Tube, swivel lid Series R1608 Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 600 mm Pitch: 143 mm E-Tube, swivel lid R4.112 series Inner height hi: 112 mm Inner widths Bi: 200 - 400 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA Classification Report IG 1303-640, tested series E4.32.10.063.0 E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Assembly instruction video Assembly video with accurate description for joining, splitting and opening e-chains® and e-tubes. Installation instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E 4.1 E4.1-E-Chain® with 4-piece structure Smooth, cable friendly inner surfaces Low noise operation through integrated "brake" on the radial stop dogs Sound dampers as an additional noise-reducing option Wide application range Numerous interior separation options Large accessory kits Widths up to 2000 mm through extension links To open on both sides Max. travel distance: Over 200 m Typical industrial sectors and applications: Krane Indoor Cranes Composting systems Sewage treatment plants Machine tools General mechanical engineering Materials-Handling Technology Refrigeration engineering Construction machinery Wood working Robotics and handling systems IPA classification -Report IG 1303-640, tested E4.32.10.063.0 41 dB(A) determined at the igus® laboratory, v = 1.8 m/s unsupported ESD classification: Electrically conductive ESD/Atex versions on request System E4.1 proven in long travels e-tubes available as special design with HT material for 850°C hot chips

Request for a quote

IGUS® GMBH

Germany

Overview for E2/000 advantages Other information Series EF2.21 Inner height hi: 21 mm Inner widths Bi: 25 - 50 mm bending radii R: 35 - 180 mm Pitch: 33.3 mm E-Chain®, snap-open along the outer radius Series 1500 Inner height hi: 21 mm Inner widths Bi: 15 - 125 mm bending radii R: 35 - 180 mm Pitch: 33,3 mm E-Chain®, snap-open along the outer radius Series 1400 Inner height hi: 21 mm Inner widths Bi: 15 - 125 mm bending radii R: 35 - 180 mm Pitch: 33,3 mm E-Chain®, snap-open along the inner radius Series 1450 Inner height hi: 21 mm Inner widths Bi: 15 - 125 mm bending radii R: 35 - 180 mm Pitch: 33,3 mm Half energy tube, snap-open along the inner radius Series 1480 Inner height hi: 21 mm Inner widths Bi: 15 - 125 mm bending radii R: 35 - 180 mm Pitch: 33,3 mm Full energy tube, snap-open along the inner radius Series 2500 Inner height hi: 25 mm Inner widths Bi: 25 - 125 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain®, snap-open along the outer radius Series 2400 Inner height hi: 25 mm Inner widths Bi: 25 - 125 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain®, snap-open along the inner radius Series 2450 Inner height hi: 25 mm Inner widths Bi: 25 - 125 mm bending radii R: 100 - 250 mm Pitch: 46 mm Half energy tube, snap-open along the inner radius Series 2480 Inner height hi: 25 mm Inner widths Bi: 38 - 103 mm bending radii R: 100 - 250 mm Pitch: 46 mm Full energy tube, snap-open along the inner radius Series 2700 Inner height hi: 35 mm Inner widths Bi: 50 - 175 mm bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, snap-open along the outer radius Series 2600 Inner height hi: 35 mm Inner widths Bi: 50 - 175 mm bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, snap-open along the inner radius Series 2650 Inner height hi: 35 mm Inner widths Bi: 50 - 175 mm bending radii R: 100 - 250 mm Pitch: 56 mm Half energy tube, snap-open along the inner radius Series 2680 Inner height hi: 35 mm Inner widths Bi: 50 - 100 mm bending radii R: 100 - 250 mm Pitch: 56 mm Full energy tube, snap-open along the inner radius Series 3500 Inner height hi: 45 mm Inner widths Bi: 50 - 255 mm bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, snap-open along the outer radius Series 3400 Inner height hi: 45 mm Inner widths Bi: 50 - 255 mm bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, snap-open along the inner radius Series 3450 Inner height hi: 45 mm Inner widths Bi: 50 - 255 mm bending radii R: 150 - 300 mm Pitch: 67 mm Half energy tube, snap-open along the inner radius Series 3480 Inner height hi: 45 mm Inner widths Bi: 75 - 115 mm bending radii R: 150 - 300 mm Pitch: 67 mm Full energy tube, snap-open along the inner radius Series 255 Inner height hi: 24 mm Inner width Bi: 25 mm Bending radii R: 55 - 250 mm Pitch: 27.8 mm E-Chain®, snap-open along the outer radius CRC series. 255 Inner height hi: 24 mm Inner width Bi: 38-103 mm Bending radii R: 150 - 250 mm Pitch: 27.8 mm e-chain® Series CRC. 255 Assembly tool E"2/000 e-chains® - quick opening with assembly tools. Assembly tool Overview E2/000 bow chains Two-part - the E2 standard as clamp chain version Overview E2/000 bow chains ESD classification: Electrically conductive ESD/Atex versions on request IPA classification: ISO cleanroom class 3 (DIN 14644-1), at v=2 m/s, with standard material igumid G Series 2500.05.055.0 UL94 V0 classifications on request 46 dB(A) determined at the igus® laboratory, v = 1.0 m/s unsupported, e. g. Series 2600.05.075.0 iF Design Award for the E2/000 series EF2.21 Overview for E2/000 advantages Other information Series EF2.21 Inner height hi: 21 mm Inner widths Bi: 25 - 50 mm bending radii R: 35 - 180 mm Pitch: 33.3 mm E-Chain®, snap-open along the outer radius Series 1500 Inner height hi: 21 mm Inner widths Bi: 15 - 125 mm bending radii R: 35 - 180 mm Pitch: 33,3 mm E-Chain®, snap-open along the outer radius Series 1400 Inner height hi: 21 mm Inner widths Bi: 15 - 125 mm bending radii R: 35 - 180 mm Pitch: 33,3 mm E-Chain®, snap-open along the inner radius Series 1450 Inner height hi: 21 mm Inner widths Bi: 15 - 125 mm bending radii R: 35 - 180 mm Pitch: 33,3 mm Half energy tube, snap-open along the inner radius Series 1480 Inner height hi: 21 mm Inner widths Bi: 15 - 125 mm bending radii R: 35 - 180 mm Pitch: 33,3 mm Full energy tube, snap-open along the inner radius Series 2500 Inner height hi: 25 mm Inner widths Bi: 25 - 125 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain®, snap-open along the outer radius Series 2400 Inner height hi: 25 mm Inner widths Bi: 25 - 125 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain®, snap-open along the inner radius Series 2450 Inner height hi: 25 mm Inner widths Bi: 25 - 125 mm bending radii R: 100 - 250 mm Pitch: 46 mm Half energy tube, snap-open along the inner radius Series 2480 Inner height hi: 25 mm Inner widths Bi: 38 - 103 mm bending radii R: 100 - 250 mm Pitch: 46 mm Full energy tube, snap-open along the inner radius Series 2700 Inner height hi: 35 mm Inner widths Bi: 50 - 175 mm bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, snap-open along the outer radius Series 2600 Inner height hi: 35 mm Inner widths Bi: 50 - 175 mm bending radii R: 63 - 250 mm Pitch: 56 mm E-Chain®, snap-open along the inner radius Series 2650 Inner height hi: 35 mm Inner widths Bi: 50 - 175 mm bending radii R: 100 - 250 mm Pitch: 56 mm Half energy tube, snap-open along the inner radius Series 2680 Inner height hi: 35 mm Inner widths Bi: 50 - 100 mm bending radii R: 100 - 250 mm Pitch: 56 mm Full energy tube, snap-open along the inner radius Series 3500 Inner height hi: 45 mm Inner widths Bi: 50 - 255 mm bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, snap-open along the outer radius Series 3400 Inner height hi: 45 mm Inner widths Bi: 50 - 255 mm bending radii R: 75 - 300 mm Pitch: 67 mm E-Chain®, snap-open along the inner radius Series 3450 Inner height hi: 45 mm Inner widths Bi: 50 - 255 mm bending radii R: 150 - 300 mm Pitch: 67 mm Half energy tube, snap-open along the inner radius Series 3480 Inner height hi: 45 mm Inner widths Bi: 75 - 115 mm bending radii R: 150 - 300 mm Pitch: 67 mm Full energy tube, snap-open along the inner radius Series 255 Inner height hi: 24 mm Inner width Bi: 25 mm Bending radii R: 55 - 250 mm Pitch: 27.8 mm E-Chain®, snap-open along the outer radius CRC series. 255 Inner height hi: 24 mm Inner width Bi: 38-103 mm Bending radii R: 150 - 250 mm Pitch: 27.8 mm e-chain® Series CRC. 255 Assembly tool E"2/000 e-chains® - quick opening with assembly tools. Assembly tool Overview E2/000 bow chains Two-part - the E2 standard as clamp chain version Overview E2/000 bow chains IPA Classification Report IG 1303-640-1, tested 1500.050.038.0 at v = 0,5 / 1,0 / 2,0 ISO Class 2, according to DIN EN ISO 14644-1 E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining and separating of chain links, filling of the E-Tubes. Assembly Instructions System E2/000 Recommended installation accessories Application examples Applications in various industrial sectors and in the igus® test laboratory. System E2/000 The E2 standard Quickly opened from the right or left with a screwdriver or by hand - opening mechanism accessible from above Lightning fast installation using thumb - safe seat without additional closing mechanism The separators and interior separation sit safely, even when the E-Chain® is open Excellent mechanical stability; design and material provide long service life Typical industrial sectors and applications General construction machinery Materials handling technology Construction machinery Wood machines Machine tools Glass machines Plastic machines Long travels Semiconductor Theater and entertaining industry Vehicles And much more ESD classification: Electrically conductive ESD/Atex versions on request IPA classification: ISO cleanroom class 3 (DIN 14644-1), at v=2 m/s, with standard material igumid G Series 2500.05.055.0 UL94 V0 classifications on request 46 dB(A) determined at the igus® laboratory, v = 1.0 m/s unsupported, e. g. Series 2600.05.075.0 iF Design Award for the E2/000 series EF2.21

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: To stabilize cleaning tools HP swivel joints serve to stabilize chain cutters, floor cleaners and other cleaning tools inside the pipe. Advantages: stabilize tools inside the pipe, facilitate tool assembly.

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: To stabilize cleaning tools HP swivel joints serve to stabilize chain cutters, floor cleaners and other cleaning tools inside the pipe. Advantages: stabilize tools inside the pipe, facilitate tool assembly.

Request for a quote

IRUS-SYSTEM

Germany

The „Irus“ presentation uprights are not only suitable as information panels but also as partition panels. The presentation uprights are easy to erect without requiring special tools. Assembly is straightforward thanks to the connectors that are already mounted on the hinged frame. The presentation uprights are available in DINA1 or DINA0 with versions for use either on one side or both sides.

Request for a quote

IRUS-SYSTEM

Germany

The flexible aluminium profile with its manifold application possibilities. Whether information panel, panel or partition, the flexi-long aluminium profile is the answer. The Irus panels are easy and quick to assemble without requiring a special tool. The panel is ideal for use both indoors and outdoors (e.g. urban facilities or schools, exhibitions, trade fairs, museums, public areas etc. The panels can be extended with our attachment modules (180° or 90°-270°) to meet the application requirements which means that highest flexibility is guaranteed. To perfect your presentation, we also offer the accessories, e.g. flexible or straight hinged frame, brochure holder, table and lighting).

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Scope of delivery: 1x ball unit table 6x freely positionalable stop bar – long 4x freely positionalable stop bar – short 1x set of bolts anti-tilting Load capacity for tools, dies, injection moulding tools, assembly goods etc. up to: 500 kg – higher loads possible with ball units 022.100 Purposes Setup and dismantling, internal transport, flexible work table e.g. in toolmaking, can be used for forklift trucks, pallet trucks or pallet jacks Advantages Reduced set-up time, safe, flexible, universally applicable, simple and fast handling Safety at work flexible fall protection for conveyed goods, simple and quick tilt protection, stop bars freely positionable in the grid The SUTTY has a CE mark – Quality, made by Schulz!

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

State-of-the-art crane systems move the heaviest construction and production components on construction sites and in production halls. MACK solutions are available to help you make the most of your potential! Cranes and hoists are mostly used in demanding situations, where space is limited and conditions are very hot or cold, very damp or very dry. This means: Even under the toughest indoor or outdoor conditions, extension arms and grippers have to be reliably supplied with energy and data in order to carry our their lifting operations without any disturbances. With our carbon brush components we support you as system suppliers, finding ‘your’ solution, no matter where you are in the development process. Design, manufacturing, tool making and assembly – all from a single provider. And done in-house. Applications in crane technology Our solutions Our services

Request for a quote

FÖHRENBACH GMBH

Germany

Rotary tables with direct drive series RT3 The rotary tables with direct drive are available in different types: RT3A100x100, RT3A100x155, RT3A080x130, RT3A150x100, RT3A150x130, RT3A250x170, RT3A200x060 und RT3G630x225 Rotary tables RT3G630 – high dynamics, high precision, high loading capacity This direct driven rotary table RT3G630 has particularly been developed for machine tool industry and assembly machines. It is characterised by its high precision, highdynamics and its high loading capacity. The rotary table is driven by a permanently excited 3-phase synchronous motor. The rotary plate and the housing are made of gray cast iron.

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Flexible monitor arm with desk clamp. The screen can be evenly adjusted thanks to the internal gas springs. • Swivelling monitor mount with desk clamp for 1 screen • Height, tilt and position of the monitor can be adjusted easily and individually to facilitate ergonomic working • Can be rotated 360° for working in portrait or landscape mode • Integrated safety system protects from injury from moving components • Tidy cable management thanks to three individually attachable cable clips (included) • Easy assembly, tools included • Universal VESA mount (75 x 75 mm or 100 x 100 mm) • For standard or curved monitors from 21″ to 27″ (53.34 cm to 68.58 cm) weighing 3 to 8 kg • Desk clamp for desk thicknesses from 14–44 mm • 10-year warranty • Made in Germany • High-quality materials for a long lifespan: Aluminium and premium plastic • Environmentally friendly in accordance with ISO 14021

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ETH MESSTECHNIK GMBH

Germany

Particularly suitable for small screwing tools 4 torque range from ± 0 - 0,5 Nm to ± 0 - 5 Nm digital output Square drive or hexagon drive No service needed because of contactless data acquisition High accuracy due to frequency modulation and strain gage technology reduced power consumption High noise immunity due to digital signal very compact design Automotive industry Test benches Assembly applications Pulsed tools

Request for a quote

ETH MESSTECHNIK GMBH

Germany

No service needed because of contactless data acquisition High accuracy due to frequency modulation and strain gage technology Single power supply High noise immunity due to amplified active signal integrated sensor-detection chip for use with GMV2 analyzer automotive industry test benches assembly applications pulsed tools hexagonal drive 7 Measurement range from ± 0 - 1 Nm up to ± 0 - 20 Nm optionally with angle measurement

Request for a quote

GEDA GMBH

Germany

Rope hoists especially for scaffolders Two lifting speeds, an overload protection and a slack rope switch as well as a variety of different load receptacles make these fast scaffold assembly hoists the ideal tool for rationally and safely transporting scaffold components and building materials. You do not need to transport the handy drive of the rope drum to the top. It can simply be installed to the scaffold on the bottom. You can install the lightweight swivel arm in the desired height to the scaffold on the top. Quick assembly and their easily being moved are the biggest advantages of the GEDA scaffold assembly hoists. The maximum working height of 40m can be extended to 76m if you install the winch in a higher position. Apart from scaffolders, it is mainly roofers and painters who use these speedy tools to transport their materials onto the scaffold.

Request for a quote

GEDA GMBH

Germany

Rope hoists especially for scaffolders Two lifting speeds, an overload protection and a slack rope switch as well as a variety of different load receptacles make these fast scaffold assembly hoists the ideal tool for rationally and safely transporting scaffold components and building materials. You do not need to transport the handy drive of the rope drum to the top. It can simply be installed to the scaffold on the bottom. You can install the lightweight swivel arm in the desired height to the scaffold on the top. Quick assembly and their easily being moved are the biggest advantages of the GEDA scaffold assembly hoists. The maximum working height of 40m can be extended to 76m if you install the winch in a higher position. Apart from scaffolders, it is mainly roofers and painters who use these speedy tools to transport their materials onto the scaffold.

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

Variable cable routeing with superior strength and durability Open, robust wire-tray trunking systems offers excellent cable routeing solutions in challenging industries such as telecommunications and IT, the food industry and chemical industry as well as machinery and equipment. The system is approved in accordance with UL and DNV for offshore use. Your advantages: Open, easy to manage cable layouts Safe, very strong and corrosion-resistant construction Easy assembly and installation with two tools and two types of connectors Easy to clean, good ventilation Wire-tray Trunking is available in various cross sections from 53 mm x 46 mm to 620 mm x 110 mm and in heights of 60 mm and 100 mm, as mini-trunking from 40 mm x 20 mm in U-, C- and G-formats and as flat trays.

Request for a quote

GEDA GMBH

Germany

Rope hoists especially for scaffolders Two lifting speeds, an overload protection and a slack rope switch as well as a variety of different load receptacles make these fast scaffold assembly hoists the ideal tool for rationally and safely transporting scaffold components and building materials. You do not need to transport the handy drive of the rope drum to the top. It can simply be installed to the scaffold on the bottom. You can install the lightweight swivel arm in the desired height to the scaffold on the top. Quick assembly and their easily being moved are the biggest advantages of the GEDA scaffold assembly hoists. The maximum working height of 40m can be extended to 76m if you install the winch in a higher position. Apart from scaffolders, it is mainly roofers and painters who use these speedy tools to transport their materials onto the scaffold.

Request for a quote

FATH GMBH

Germany

For precise positioning of dollys or material trolleys suitable for different wheel diameters no brakes needed self-adhesive, for tool-free assembly no screwing required, immediately ready for use Models: High / high, for light to medium weights Low / high, for medium to heavy weights Low / low, for heavy weights Different lengths available on request. Material: Alumnium Surface: Plain Extra accessories possible Compatible One-piece end caps; self-adhesive, screwable with optional screw-on set Yellow position markings with signal effect to indicate the position of the wheels from floor dollys or material trolleys in the parking rail Plastic PA, glass ball reinforced

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

- zero-gravity ability - tool handling - tool positioning - ergonomic work place - assembly / production - tool support - quality made in germany

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

- zero-gravity ability - tool positioning and handling - ergonomic tool support - assembly / production - made in germany

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quoteResults for

Assembly tools - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Lifting equipment (7)

- Driveshafts and micro-motors - electric (4)

- Hoists and elevators, construction (3)

- Measurement and control instruments (3)

- Electric and electronic components - machines for manufacturing (2)

- Assemblies, hydraulic (1)

- Cable ducts (1)

- Advertising brokers - agencies (1)

- Bearings, roller (1)

- Conveyor belts (1)

- Handling trolleys (1)

- Mechanical transmission - components (1)

- Office machines and equipment (1)

- Plumbing, domestic (1)

- Promotion - consultants (1)

- Security - Services (1)

- Thermoforming, plastics - machinery (1)