- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- as rubber

Results for

As rubber - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine provides high efficiency cleaning of medical and technical elastomers and is construed for big sized batch demands at high throughput. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W90 offers maximum economic efficiency on treatment of big batch volumes at high throughput!

Request for a quote

WILHELM-PLASTIC GMBH & CO KG

Germany

In the production of rubber grommets and rubber seals, we use tools with special coatings and tooling concepts that prevent the adhesion of rubber parts (including TPE, EPDM). With this protocol, we guarantee safe mass production.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

In the cryogenic blasting process, an enrichment of rubber and plastic waste powder takes place due to fine abrasion during the treatment procedure. Thus the performance and processing time of the blasting-media will deteriorate and decrease its jet-energy. In our cryognic deflashing machines, the blasting-media is primary screened by the treatment drum perforation, however, after a long operating time the amount of rubber and plastic waste powder increases. In order to guarantee a constant, statistically secure and economic processing, this powder has to be removed periodically from the blasting-media. Our automatically working blasting-media recovery machine consists of a suction & drying system and a vibrating-screen unit. The used blasting-media has to be aspirated manually from the deflashing machine. The drying of the polluted wet and cold media takes place in the suction tank and the cleaning by screening with final separation into waste powder, waste media & re-usable media,

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This automatic washing & drying system provides high efficient cleaning of elastomers in through-feed method (on option washing with de-ionized, de-mineralized or ultra-pure water possible). Starting from the loading station, the washing drums are conveyed automatically to each washing station (→ station pre-washing → station rinsing → station high pressure cleaning → station high pressure drying) and are finally conveyed to the unloading station after treatment. The dimensions of this system depend on the drum dimensions desired (perforation from 3 - 15 mm possible by choice). Set as our default, the models WD3, WD5 and WD9 are available with different sizes. For industry 4.0 demands, this system is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. Siliconisation or other coating of elastomers is possible on option.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine provides maximum economic efficiency at treatment of big batch volumes at high throughput! The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. At any time, this machine is ready for upgrade to automated application, from the automatic loading & deloading of the machine up to a complete full automated feeding & forwarding system. For industry 4.0 demands, the E90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum-only deflashing), suitable for special applications only.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine offers high efficiency cleaning of medial & technical elastomers and is construed for mid sized bach demands. The W40 is, like any of our machines, designed for high performance with economic efficiency. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W40 is best prepared. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W40 is the optimal solution for mid-sized batch demands at high througput!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine is the optimal solution for mid-sized batch demands at fast throughput times! The E 40 is, like any of our machines, designed for high performance at low consumption of nitrogen, blasting media and electric energy. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. For industry 4.0 demands, the E40 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum only deflashing), suitable for special applications only. mid-sized batches > fast throughput times > E40

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small sized computer controlled deflashing machine can be integrated into the production line easily. This saves temporary storage or extra transports and finally corresponding time loss and costs. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. Alternatively the E30 is available with quick-exchange basket system. This basket is compatible to our high-pressure washing machine W30 and furthermore optimally suited for a linear in-line-processing →production →deflashing →washing →termpering, as this charge-baskets may be used compatible for each machine. For industry 4.0 demands, the E30 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small-sized machine can be integrated into the production line easily. This safes temporary storage or extra transports and finally corresponding time loss and costs. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. By special request, siliconisation or coating with other glide agents is also possible. The W30 uses exchangeable bastekts for the (un)loading. These baskets are also compatible to our cryogenic deflashing machine E30W, and furthermore, optimally suited for a linear in-line processing → production → deflashing → washing → postcure tempering, The W30 is best pepared for industrie 4.0 demands. (on option with OPC UA server) With this small-sized machine, your treatment capacity is at best cost-performance ratio!

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We manufacture customer-specific molded parts made of rubber, silicone and elastomer composite parts in small and large series production according to your sample or drawing. Molded rubber parts are generally characterized by their good formability, chemical resistance, pressure and abrasion resistance and good electrical properties. We advise you in detail on the selection of the suitable material, with a view to the functional description, temperature resistance, chemical requirements, weather influences and resilience. Our molded parts are used in all industries, such as the automotive industry, medical technology, mechanical engineering and electronics industry. We offer customized parts: Protective covers for input devices, Rubber seals and rings, Grommets, flanges, bellows, Form Tubes, Rubber damper, PU molded parts (e.g. wheels and rollers) Combined rubber-metal parts / rubber-plastic parts, etc.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Thanks to latest digital technoloy, we can meet your demands at a high professional level. We provide 2D/3D measurement (e.g. dimension measurements, burr measurements, grain size analysis, residual contamination analysis according to ISO 16232 & VDA 19, profile measurements, particle analysis, 3D presentation) with multi-lightning view for various illumination angles, optical shadow effects to clearly identify smallest univenness, reflexion reduction and HDR-view for high colour graduation. Several types of perspectives are possible thanks to a pivoted angle of sight (up to 90°) or by adjusting the mobile object lense (e.g. hollow spaces). We compile a detailed documentation including pictures or videos, where even real-time swivellling views can be recorded. We are looking forward to receiving your enquiry!

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

OUR IN-HOUSE TEST PLANT AND LAB In order to ensure the high quality and long service life of our agitators, we have set up an in-house plant for testing our agitators. At the end of the manufacturing process, all of our agitators undergo a specific test procedure with a final test run. Here, we can test agitators with a shaft length of up to twelve meters. When designing our agitators, we use fluid mechanics simulations in our in-house laboratory. All Geppert mixing systems are delivered with O&M Manual and worldwide technical service.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

For over 50 years, Geppert Ruhrtechnik has stood for quality and reliability in agitator construction. We develop, manufacture, and distribute innovative agitators for all applications in the materials processing industries, such as the chemical, pharmaceutical, biotechnology, and food industries, as well as in water and wastewater treatment. Our many years of experience make us the perfect partner for both standard and special applications. When selecting and designing our agitators, we draw on our many years of experience, internal databases, and state-of-the-art tools (such as FEM, Finite Element Method, and CFD, Computational Fluid Dynamics), as well as our own fluid mechanical laboratories. This means we always provide you with the optimal solution. In addition to our agitators, we manufacture suitable containers and stands for stand-alone, wall mounted, and mobile designs. We can implement these in your plants, taking into account any its specific requirements.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Despite the increasing level of digitalization, an ever-increasing demand for paper and pulp products can be observed. However, a shift is taking place from print paper qualities to packaging paper and cardboard. The wide range of paper products requires a variety of production processes. These include mechanical and chemical processes which, depending on the form and variant, produce different pulp qualities. Stirring and mixing are essential unit processes in all types of paper and pulp production. Mixing tasks range from liquid/liquid or gas/solid/liquid mixtures, through mixing of complex liquids, and include mixing of chemically reactive components. Improving and optimizing mixing processes in the paper and pulp industry can lead to end product improvements; such as increased strength, improved luster, or significant energy or chemical savings.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Geppert Ruhrtechnik offers you a modern working environment with extensive additional services, individual training and further education opportunities as well as health offers. Whether you are a pupil, student, graduate or experienced professional: with us you can contribute your knowledge and skills in a targeted manner. We look forward to committed and passionate people who want to work together towards our goals.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Geppert Ruhrtechnik GmbH has been a certified manufacturer of explosion-proof agitator drives since 2003. This made us one of the first companies to develop and produce ATEX-compliant agitators. Our agitators are certified to ATEX Directive 2014/34/EU (formerly Directive 94/9/EC) in gas or dust explosion-proof designs. In addition, the majority of agitator styles have type test certificates for explosive zone 0, and can be used in applications in which an explosive atmosphere, arising from a mixture of air with flammable substances in the form of gas, vapor, or mist, is present. We offer ATEX-compliant controls for our explosion-proof design agitators. Talk to us and make use of our many years of experience on the topic of explosion protection. We will be happy to assist you! Our services in the field of explosion proof agitators

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

In the manufacture of semiconductors, agitators are mainly used in conditioning of polishing and cutting suspensions, etchants and other auxiliary chemicals, cleaning solutions, or in chemicals recycling. Requirements placed on stirring systems are extremely demanding. Almost always, clean room conditions prevail, meaning that drives and seals must be designed with no abrasion or leakage. Parts that come into contact with the medium, such as the shaft and stirring element, often have to be produced with metalfree surfaces due to the aggressiveness of the media and the purity requirements. Also in this area, Geppert Ruhrtechnik can look back on a very successful history. All well-known chip manufacturers belong to our client base, as well as the manufacturers of the specialty chemicals used in this field. In addition, our agitators are used in broad solar cell production areas.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEPPERT RÜHRTECHNIK GMBH

Germany

Mixing technology is particularly wide-ranging in the food and drinks industry. From simple suspension and homogenization tasks in storage or transport containers, right through to complex reduction tasks, during which mixtures can be exposed to only the lowest of shear forces – you will find it all in the food and beverages industry. High food sensitivity and the multitude of fields of application for agitators require close process coordination with the customer, in order to design, construct, and finish the agitators in the optimal manner with the widest variety of mixing elements. In addition to its popular standard mixers, Geppert also has special stirring elements within its portfolio, capable of being extremely gentle on the product while remaining highly efficient. All agitators have the relevant food approvals and can also be supplied with clean room drives and special sealing systems.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The pharmaceutical and biotech industry involves a wide range of mixing tasks, for which precision and consistence are of utmost importance. Particles must be evenly suspended and homogenized in liquids for filling processes. In some cases, multiple processes, such as for example heat transfer, rapid mixing, or material transport, must take place simultaneously within one reactor. Specific requirements are often placed on the drives, if for example production is carried out under clean room conditions. The surface quality of the stirring elements must always meet the highest standards; they are therefore usually electropolished. Our agitator solutions for the pharmaceutical and biotech industry are engineered and manufactured to customer-specific requirements. Selection of the agitator, as well as of the drive and sealing concepts, depends on the process and customer specifications. We will provide all the necessary design calculations, or simulate the mixing process.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Paints and coatings play a significant role in our lives. Without them, life would be dull and even monotonous. But they don’t just provide color. They perform a multitude of other tasks as well. For example, they protect objects or structures from corrosion and deterioration, thus contributing to the sustainable use of resources. Equally, special coatings can contribute to a reduction in flow resistance, or create a pearled finish that makes objects easier to clean and reduces contamination. Paints and coatings generally consist of binders, fillers, pigments, solvents, resins, and perylene, as well as additives. These substances must be mixed together homogeneously during the production process. Various agitators are used to achieve this, for example dissolvers, depending on the process step and according to the boundary conditions.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Mixing of substances and chemical reactions are closely interconnected. The way in which different reagents are mixed together can have a significant influence on product quality, product yield, or even on the resulting product itself. Stirred reactors are used in the chemical industry for a range of applications. They can be used for reaction, extraction, distillation, crystallization, and other processes. Depending on the reactor process and operating mode (continuous, semi-batch, or batch operation), the agitators used can be subjected to varied demands. In the petrochemical industry, emulsification, absorption, desalination, alkylation, or neutralization processes are commonly found; lubricating oils must be homogenized or sludge oils suspended. For this wide variety of mixing tasks, Geppert offers tailor-made agitators to satisfy operational and customer requirements.

Request for a quote

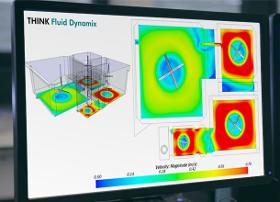

GEPPERT RÜHRTECHNIK GMBH

Germany

Challenging, customer-specific mixing technology solutions can be numerically simulated as early as during the planning phase, and the results analyzed. This means increased design confidence, high-quality solutions and, as a result, reduced project durations and costs. Our experts from THINK Fluid Dynamix® are specialists in the application of numerical techniques such as flow simulation in real time and artificial intelligence methods for automated optimization. This enables processes, such as stirring and homogenization, to be analyzed more accurately under consideration of all applicable process parameters, and complex tasks to be processed far more efficiently. These methods set entirely new standards in terms of design reliability and efficiency. Allow us to contribute to your success!

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The SV 30 is a small stand mixer with manual stroke adjustment and spring suspended lid for small batches that range in volume from 20 l up to 100 l and agitator drives of up to 1.5 kW. It is supplied with helical gear agitators of up to 0.75 kW or fast running agitators of up to 1.5 kW and the suitable mixing elements. Thanks to the H stand as well as two hook blocks, the SV 30 can be moved. The weight is balanced by means of a counterweight positioned in the stand column itself. The pneumatic supply is guided through a laterally mounted energy chain. Explosion-proof design ATEX 2014/34/EU feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Double column wall mounted stand mixer/floor stand mixer Rigid stand for wall-mounting or floor stand for mixers from 100 kg. The stand consists of 2 u-shaped columns with a ball-borne support slide with a cantilever beam for the mixer. The double-column stand allows the processing of tank volumes up to 4 m3, depending on the tank dimensions. Mixer powers up to 75.0 kW and support loads up to 1,000 kg can be realized. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching agitator elements. The lift is done electrically by a lift drive and chain drive. The electric supply is guided through a laterally mounted energy chain. Customized solutions for instance a stand mixer with H foot or stand equipped with coaxial agitator type KRK are feasible.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

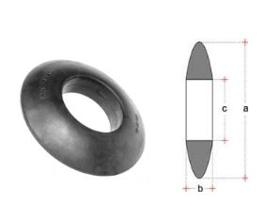

Support rings for type A carrying rollers Type A support rings prevent sap build up and the build up of dirt on the carrying rollers and ensure a straight run in the bottom strand. Support rings (rubber rings) from FTK Förderband Technik Kilian GmbH are attached permanently to the roller and are characterized by their abrasion resistance. In addition to the proven standard, we also manufacture special quality rings such as white food quality rings, oil and grease resistant rings, and rings for extreme temperature ranges ( 40° C to 180° C). Support rings for type B carrying rollers Rollers fitted with type B support rings are used as bottom belt rollers. They are generally placed on the ends of the carrying rollers. Support rings (rubber rings) from FTK Förderband Technik Kilian GmbH are attached permanently to the roller and are characterized by their abrasion resistance.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

We stock skirting rubber, belt cleaning rubber seals, nap rubber seals. Sheet rubber with or without contact layer available in different specifications and dimensions.

Request for a quote

ROLKO KOHLGRÜBER GMBH

Germany

We offer quality slip rollers, keel rollers, rolls, wheels among other products for the boat trailer industry. Our products are certified and tested according to the latest European norms and quality standards. More information about our products and services can be found in our catalogues. Do you have questions about our products or do you want to request a quote? Please contact us. We have the right accessory for your boat trailer!

Request for a quote

ROLKO KOHLGRÜBER GMBH

Germany

We offer quality keel rollers, slip rollers, rolls, wheels among other products for the boat trailer industry. Our products are certified and tested according to the latest European norms and quality standards. More information about our products and services can be found in our catalogues. Do you have questions about our products or do you want to request a quote? Please contact us. We have the right accessory for your boat trailer!

Request for a quoteResults for

As rubber - Import exportNumber of results

39 ProductsCountries

Company type

Category

- Chemical and pharmaceutical industry - machinery and equipment (14)

- Rubber - industrial machinery and equipment (7)

- Rubber products (6)

- Rubber seals (5)

- Boat trailers (2)

- Wheels, castors and rollers - rubber (2)

- Compensators (1)

- Coupling, pneumatic (1)

- Gas and oil - exploitation (1)

- Industrial analysis laboratory (1)

- Moulding, rubber - machinery (1)

- Moulds, plastic and rubber industry (1)

- Rubber and plastic forming (1)