- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- angle valves

Results for

Angle valves - Import export

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Compact right angle motor valve made from stainless steel for on/off and control operation, ideal for installations where space is limited and for use with neutral and aggressive media. The valve is a perfect alternative to pneumatic valves if compressed air is unavailable, on request with failsafe option. Whitworth pipe thread NPT thread Positioner electronics, limit switch, position feedback All control actuators are also available with fail safe feature. Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic right angle control valve with integrated positioner for high cycle applications and compact installations. Due to the stainless steel design suitable for neutral and aggressive media but also for a wide range of temperature applications. Whitworth pipe thread NPT thread Whitworth pipe thread NPT thread Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic right angle valve for high cycle applications and compact installations. In stainless steel suitable for neutral and aggressive media but also for a wide range of temperature applications. Whitworth pipe thread NPT thread Limit switch Pilot valve Manual override . . . Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated angle seat flange valve for high switching powers. In stainless steel design also suitable for neutral and aggressive media. The angled seat design offers a high flow rate, the flange connection offers easy installation. Flange acc. to DIN EN 10921 Flange acc. to ANSI #150, ANSI#300 Limit switch Pilot valve Manual override . . .Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuatorLow temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatically operated angle seat valve is the extremely reliable allrounder in valve technology and is predestined for very high switching capacities. In stainless steel design for neutral and aggressive media but also for a wide range of temperature applications suitable. The angled seat design offers a high flow rate. Whitworth pipe thread NPT thread Welding ends Triclamp connection Special connections Limit switch Pilot valve Manual override . . . Stainless steel Bronze Brass Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Pressure balanced version Version with approval according to DIN 161 Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat control valve type 7025 with integrated digital positioner is specially adapted for use in the food and beverages production. Suitable for controlling product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Highly accurate angle seat motor valve for on/off and control operation with neutral and aggressive media. A version with failsafe option is available. Positioner electronics, limit switch, position feedback All control actuators are also available with fail safe feature.Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Compact angle seat motor valve for on/off and control operation with neutral and aggressive media. A version with failsafe option is available.Whitworth pipe thread NPT thread Welding ends Triclamp connection Special connectionsPositioner electronics, limit switch, position feedback All control actuators are also available with fail safe feature. Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Angle seat motor valve for on/off and control operation with neutral and aggressive media. Universal actuator configurations with flexible accessories. Whitworth pipe thread NPT thread Welding ends Triclamp connection Special connections Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic control valve with angle seat design. The integrated positioner type 8049 means that a compact design is achieved. All parts that come into contact with the medium are made from stainless steel. Whitworth pipe thread NPT thread Welding ends Triclamp connection Special connections Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof version Piston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Highquality angle seat manual valve made from stainless steel, also suitable for neutral and aggressive media. The angle seat design offers a high flow rate.Whitworth pipe thread NPT thread Welding ends Triclamp connection Special connections

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 550 2/2-way angle seat globe valve has a low maintenance stainless steel piston actuator and is pneumatically operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. —Suitable for inert and corrosive liquid and gaseous media —All medium wetted parts can be selected to suit relevant applications —Suitable for high media temperature —Stainless steel actuator easily cleanable

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 507 2/2-way angle seat globe valve has an ergonomically designed plastic handwheel and is manually operated. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. A stainless steel bellows and a handwheel extension are available as options (not for operator size 0). —Various valve body connections (threaded sockets, threaded spigots, butt weld spigots) available —High flow rates due to angle seat design —Optionally for contact with foodstuffs as per directive (EC) No. 1935/20041 (K-no. 1935)

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 554 2/2-way angle seat globe valve has a plastic piston actuator and is pneumatically operated. The valve spindle is sealed by a self-adjusting gland packing or a compact seal cartridge, dependent on the size and version. A wiper ring or the wiper contour of the seal cartridge additionally protects the valve spindle against contamination and damage. This provides low maintenance and reliable spindle sealing even after a long service life. —Simple and fast commissioning —Good flow capability and compact design —Valve and positioner are optimally adapted to each other. (For positioner details please refer to the relevant data sheets) —Optionally suitable for contact with food according to Regulation (EC) No. 1935/2004 (K-No. 1935) —Standard gland packing suitable for vacuum up to 20 mbar (abs.)

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat valve type 7015 is ideal for applications in food and beverage production. The valve can be used to shut-off product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

BÜRKLE GMBH

Germany

IBC discharge valve with 90° hose nozzle and sealing cap. The hose can also be closed with the enclosed sealing cap. Hose nozzle external PA Ø 30 mm, suitable for flexible hoses. The IBC discharge valve is a sturdy, high-quality ball valve with a hose connection and connection adapter including seal, for standard thread S 60x6 external or 1" external, designed to fit all commonly used European IBC containers. With the appropriate thread, the discharge valve can also be screwed directly onto the original discharge valve that is already on the IBC tank if the original valve is leaking or faulty. In this way the IBC discharge valve ensures fast and reliable residual emptying of the container with good dosing. The discharge valve is an indispensable accessory to ensure a professional connection of the hose or for filling from your IBC container.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Compact flanged angle seat motor valve for on/off and modulating operation for neutral and aggressive media. Flanges acc. DIN EN 10921 Flanges acc. ANSI #150, ANSI #300 Positioner electronics Limit switches Position feedback. All control actuators are also available with fail safe feature. Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Pneumatic control valve with angle seat design. The angle seat design offers a high flow capacity, the flange connection an easy installation. The integrated digital or analogue positioner is coming along with a very compact design. All wetted parts are made from stainless steel. Flange acc. to DIN EN 10921 Flange acc. to ANSI #150, ANSI#300 Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof versionPiston actuator of Brass (chrome plated) Stainless steel Polymer Stainless steel diaphragm actuator Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version …

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The 3A compliant hygiene right angle valve type 6052 with integrated positioner was specially developed for applications in the dairy industry, but also in food and beverage production. The 6052, available in nominal sizes DN15 to DN50, meets the highest requirements for purity and control quality. All wetted parts comply with FDA and regulations (EG) 1935/2004 and (EU) 10/2011.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The aseptic right angle valve type 6051 with EHEDG Certification and integrated positioner type 8049 is perfectly suitable for applications in pharmaceutical and food processing industry as well as in the biotechnology and cosmetics. All wetted parts comply with FDA, USP class VI and regulations (EG) 1935/2004 and (EU) 10/2011.

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Angle Drilling Machine Valve Opener

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Drilling Machines Hydraulic Core Drills Hydraulic Earth Augers Hydraulic Mounted Earth Augers Hydraulic Ground Drivers Hydraulic Post Drivers Brochure Drilling Machines Screw Drivers Hammer Drills Impact Wrenchs Hydraulic Hammer Drills Hydraulic Sinker Drills Hydraulic Impact Wrenches Hydraulic Angle Drilling Machine Valve Opener Hydraulic Post Puller Hydraulic Self Driving Drilling and Pile-Driving Machines

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

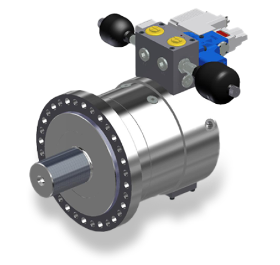

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

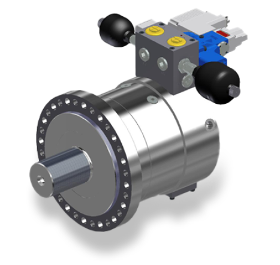

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

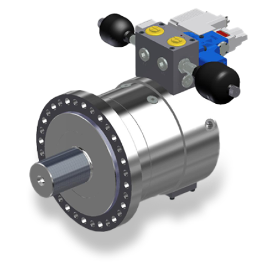

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quoteResults for

Angle valves - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Valves for pneumatic equipment (12)

- Electric motors and parts (7)

- Industrial valves, operating equipment (3)

- Paint mixers and grinding machines (3)

- Valves for industrial fittings (2)

- Food Processing (2)

- Pharmaceuticals - basic and auxiliary products (2)

- Plumbing, industrial (2)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Filters, liquid (1)

- Vehicles - mechanical components and parts (1)