- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air valves

Results for

Air valves - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the assembly parts of air valves.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve, adjustable jet

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve, pilot flame, DIN 30665

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve, pilot flame, DIN 30665

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

This micro air valve was developed specially as a small signal element for mounting in confined spaces. Its design allows a big orifice at small overall dimensions. Pre-controlled by an air outlet in the integrated tube nipple it only needs a minimum of actuating force to shut off the pilot port.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

safety pilot, thermocouple, air regulation, needle valve, pilot flame, DIN 30665

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve, tube Ø 28 mm, head Ø 32 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve, tube Ø19 mm, head Ø30 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

air regulation, needle valve for gastype from underneath, tube Ø 28 mm, head Ø 32 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

safety pilot, thermocouple, G 1/4 screwed left-hand, air regulation, needle valve, pilot flame, DIN 30665

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The BEV-G is a single-stage valve offering only the function of the first ventilation stage (coarse ventilation) provided by the two-stage valve (BEV-GF). It is not necessary to coordinate the valve to the working pressure in the first ventilation stage, since coarse ventilation is always closed under pressure. Type G (coarse ventilation): The air escapes through this valve until the medium closes it as it continues to flow. The valve remains closed under operating pressure. Ventilation of individual sections in sloped pressure lines, especially as a low pressure safety feature Quick ventilation of high points if fine ventilation is not required (short pump run times)

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTreat-R preparation and feeding system ensures an even and reliable product supply. At the same time, the medium is optimally prepared for the production process by stirring and circulating. The use of the VRP dispenser series for the further transport of the medium offers the following advantages: optimal processing of viscosities up to 50,000 mPas very low shear stress of the medium very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - no air supply necessary - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - Stator material is adapted to the medium to be pumped Application: - Feeding and processing of medium to highly sensitive media, e.g.: Silicones, adhesives, resins, greases, colour pastes, metal-filled pastes

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The BEV-F is a single-stage valve offering only the function of the second ventilation stage (fine ventilation) provided by the two-stage valve (BEV-GF). For ventilation quantities of 20 to 40 m3/h. Specific applications include high points which are under hydrostatic pressure even when the pump is shut down due to the height variation involved, and where no coarse ventilation is required, as well as at high points with low flow quantities. Type F (fine ventilation): Air escapes through this valve, and collected gases cause it to open once again, including under operating pressure, until the medium continues to flow and close the valve again. Installed at high points which are under hydrostatic pressure even when the pump is shut down due to the height variation involved, and where no coarse ventilation is required. Installed at high points of pressure lines with low flow quantities.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

Compact right angle motor valve made from stainless steel for on/off and control operation, ideal for installations where space is limited and for use with neutral and aggressive media. The valve is a perfect alternative to pneumatic valves if compressed air is unavailable, on request with failsafe option. Whitworth pipe thread NPT thread Positioner electronics, limit switch, position feedback All control actuators are also available with fail safe feature. Low temperature version Pressure balanced version Degreased version, Silicon or PTFEfree version

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

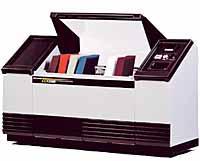

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Basic cyclic tests are used to qualify a coating or material for a specific end use on a pass-fail basis, or determine the probability of corrosion of a specific material. Applications include: Aerospace, Appliances, Automotive, Government, Marine Craft, Paints/Coatings, Research, and Telecommunications. Reinforced fiberglass cabinet, exposure lined with gel coat Solution reservoir - 35 gal (132L) Clear cover with dual magnetic Santoprene gasket (BCX9000 comes with opaque Polypropylene cover) Peaked cover prevents dripping of condensate onto sampl Exposure zone heated by titanium rod heater Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 131 °F (55 °C) - Hight temperature option up to 160 °F (71 °C) Omni-Fog Dispersion Tower or Omni-Fog II Dispersion System, fully adjustable. Built-in support ledges, front and back Wet Bottom Drain Assembly; heated, with auto fill for higher and more uniform humidity (n/a BCX11000) Air-assisted Cover Lifters on BCX9000 and BCX11000 Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) BCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 1.93 x 0.9 x 1.4 m BCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 2.46 x 0.9 x 1.4 m BCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 2.46 x 1.1 x 1.4 m BCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 2.69 x 1.32 x 2.16 m BCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 2.82 x 2.29 x 1.83 m Combination exhaust condenser and wet bottom drain assembly Recorder, 2-pen circular chart, digital display, 7 day, wet bulb and dry bulb Recorder, 6 channel strip chart; 4 temperature probes and air pressure Modem for remote trouble shooting Solution spray, two-nozzle External condensate collection package High voltage kit (over 460 VAC) Gas injection system for SO 2, CO 2, NO x High capacity oil & water extractor Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Air-actuated Cover; required for tests specifying ambient conditions Solution Spray; multiple nozzles (8, 12 or 16) with individual shut-off valves CE, UL CSA Conformance certifica High Temperature System, to operate BCX up to 71ºC / 160ºF BCX2000/BCX3000/BCX4000/BCX9000/BCX11000 SO 2 Injection; for customer-supplied SO2, customer-supplied fume hood recommended Data Recording Software; PC based, sends data to customer's computer

LACERS GMBH

Germany

Product information "Stand-up pouches, black matt with aroma valve, high barrier" Stand-up pouches, coffee bags, aroma protection packaging: with valve, black matt, with pressure lock - High Barrier These stand-up pouches are the little black dress for your products. The matt black surface gives the bag a very elegant touch. You can be sure that this bag will not fail to impress when it is on the shelf! Your customers' attention is certain. Our stand-up pouches are standing pouches and are particularly suitable for filling flavored, ground, small-scale or powdered products such as salt, rice, spices, decorative sand and much more. These bags are often used for roasted coffee. But other uses are also possible. The valve lets the air out only from the inside. The snap closure makes the bag resealable. The bag also has rounded corners, tear notches and can be sealed above the sealing lip to guarantee tamper evidence.

Request for a quote

DEKORTECH GMBH

Germany

Pneumatic heat press for textile transfers. ✔ Singe platen ✔ Even temperature and pressure ✔ Opens automatically ✔ Up to 50 x 60cm base plate ✔ Swing away 90° ✔ Pull out base plate This heavy-duty heat press is great for small to medium businesses. Due to its pneumatic closing mechanism, it is easy to operate without exhausting your arm. The pull-out base and the rotatable head make it even easier to place the textile and transfer. Furthermore, a small gap underneath the base plate allows you to thread the t-shirt onto the platen. Using a small display, you can adjust temperature and dwell time to your likings and a valve controls the air pressure. To safely operate the press, two buttons need to be pressed on each side of the machine to lower the heated element. With a range of different base platens, this press can be used for t-shirts, hoodies, bags, sleeves, legs, bags, neck tags and a lot more.

Request for a quote

LACERS GMBH

Germany

Product information "Stand-up pouches, black glossy with aroma valve" The stand-up pouch, stand-up pouch, coffee bag or the aroma protection packaging with a valve in black "glossy", with pressure lock and therefore resealable A brilliant choice. These stand-up pouches are the little black dress for your products. The shiny black surface gives the bag a very classy touch. You can be sure that this bag will not fail to impress when it is on the shelf! Your customers' attention is certain. Our stand-up pouches are standing pouches and are particularly suitable for filling flavored, ground, small-scale or powdered products such as salt, rice, spices, decorative sand and much more. These bags are often used for roasted coffee. But other uses are also possible. The valve lets the air out only from the inside. The snap closure makes the bag resealable. The bag also has rounded corners, tear notches and can be sealed above the sealing lip to guarantee tamper evidence.

Request for a quote

GSW SCHWABE AG

Germany

electropneumatic initiation via solenoid valve, e.g. 24 V DC electropneumatic pilot release via solenoid valve, e.g. 24 V DC protective cover filterregulatorlubricator to clean and lubricate the supply air manual on/off valve single/double band adaptor for surfacecritical materials telescopic guide for thin wire precision stock guide for thin materials special grippers for plate or profile materials mounting bracket with height adjustment via slotted holes heightadjustable base frames pullthru straighteners for strip and wire electropneumatic initiation via solenoid valve, e.g. 24 V DC electropneumatic pilot release via solenoid valve, e.g. 24 V DC complex electrical control units protective cover filterregulatorlubricator to clean and lubricate the supply air manual on/off valve

Request for a quote

GSW SCHWABE AG

Germany

electropneumatic initiation via solenoid valve, e.g. 24 V DC electropneumatic pilot release via solenoid valve, e.g. 24 V DC protective cover filterregulatorlubricator to clean and lubricate the supply air manual on/off valve single/double band adaptor for surfacecritical materials telescopic guide for thin wire precision stock guide for thin materials special grippers for plate or profile materials mounting bracket with height adjustment via slotted holes heightadjustable base frames pullthru straighteners for strip and wire electropneumatic initiation via solenoid valve, e.g. 24 V DC electropneumatic pilot release via solenoid valve, e.g. 24 V DC complex electrical control units protective cover filterregulatorlubricator to clean and lubricate the supply air

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – The modular process technology offers individual solutions for optimising system and process performance with the objective of increasing the efficiency of the production line, preserving productivity and reducing the environmental burden. The process technology division also plans, designs and manufactures the following process engineering solutions in the foodstuffs industry: Customer-specific valve clusters Sterile air modules Pressure vessel construction per the pressure equipment directive Cooling and heating systems Continuous mixing devices (KME) Scraping heat exchangers (SWT) Thermal product treatment Servicing / system overhauls

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

This perfectly constructed machine can be also fitted at the front with a pair of high-performance supports instead of a single one and is, therefore, the ideal tool for extreme and long-term use. It is nevertheless light and sits snugly in your hand. Due to the high speed of this grinder it creates a very clean pattern, which makes it ideal for fine grinding, milling and engraving jobs. The following variants of the machine are available: Support: Single or pair Valve: Rotary or lever valve Exhaust air direction: Backwards or forwards

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Cellular wheel sluices Cellular wheel sluices are used as discharge devices under filters, cyclones and silos, as well as for channelling materials into pneumatic conveying systems. In a special tested version, however, these can also be used at the same time for the explosive decoupling of complex plant systems in the sense of the ATEX regulations. Multi-cutter The multi-cutter is ideally suited for the chopping up of paper or plastic waste strips as well as veneer residues in extraction pipes. It works with a set of fast-rotating, but air-permeable blades. The connection diameter is DN 160 and the motor has a rated drive power of 0.75 KW. In order to be able to definitely assess the usability for the application, it is advisable to provide us with representative material samples. The assessment is also often proven by pilot plant trials. The advantage of this is that the degree of chopping can also be determined. ATEX non-return valves (EX) Non-return valves are passive decoupling elements in pipelines for preventing dust explosion effects from running in the opposite direction to the conveying direction. The non-return valves are type-tested protective systems in accordance with directive 94/9/EC, better known under the synonym ATEX 95. Function In normal operation, the top-mounted flap swims on the air stream in the housing of the non-return valve and in this way is held open. At a standstill the valve flap closes under its own weight and rests on the diagonally cut inflow pipe. If an explosion occurs behind the non-return valve, the air flow direction is reversed due to the increased counter-pressure. This causes the flap to close. The valve flap is additionally pressed against the inflow pipe by the pressure of the explosion, thus reliably sealing the pipeline against an explosion backdraught. These non-return valves function without external energy. The RSK and BPF-M series are available in the sizes DN 160, 200, 250, 280, 315, 355, 400, 450, 500, 560, 600, 630, 710, 800, 900 and 1,000. The two series differ in that they have different versions and application possibilities. The non-return valves, as type-tested protective systems, are sold through Brilex Gesellschaft für Explosionsschutz mbH, Hinterm Gallberg 15-17, D-59929 Brilon; www.brilex.de

Request for a quote

EISELE GMBH

Germany

- Whitworth pipe thread - Thread G2 for manual override - Chambered O-ring - Sealing: NBR - Material: brass nickel plated, Al black anodized - Allowable medium: air - Temperature range 14 to 158 °F (-10 to +70 °C) - Working pressure range 14,5 to 145 psi (1 to 10 bar) - Nominal flow rate measured when throttle is open at 87 psi (6 bar) and 14,5 psi (1 bar) pressure drop between inlet and exhaust

Request for a quoteResults for

Air valves - Import exportNumber of results

47 ProductsCountries

- Germany (47)

- Berlin and region (2)

- Bonn, Düsseldorf and North Rhine and Westphalia (18)

- Frankfurt am Main and Hesse (3)

- Hamburg and region (7)

- Hannover and Lower Saxony (8)

- Kiel and Schleswig-Holstein (1)

- Mainz and Rheinland-Pfalz (1)

- Munich, Nuremberg and Bavaria (4)

- Stuttgart, Freiburg and Baden-Wurtemberg (3)

Company type

Category

- Burners, industrial (11)

- Valves for pneumatic equipment (3)

- Machine tools, metal shaping - parts and accessories (2)

- Paper & Cardboard - Raw Materials (2)

- Water - production and distribution (2)

- Dosing pumps (1)

- Sandblasting equipment (1)

- Adjustment - machine tools (1)

- Cocks and valves for petroleum and petrochemical industries (1)

- Foundries - copper, bronze and brass (1)

- Measurement - Equipment & Instruments (1)

- Mechanical engineering - custom work (1)

- Metals - Machines & Equipment (1)

- Paint mixers and grinding machines (1)

- Plastics - industrial machinery and equipment (1)

- Silk-screen printing (1)