- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air exchangers

Results for

Air exchangers - Import export

ANTHERMO GMBH

Germany

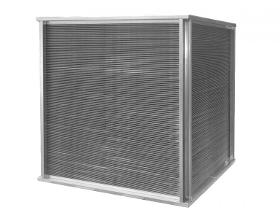

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-water heat exchangers for industrial use Three types of air-water heat exchangers Three different designs o air-water heat exchangers The Anthermo GmbH delivers three different designs of air-water heat exchangers: Finned tube heat exchangers Lamella heat exchangers Straight tube heat exchangers These heat exchangers are designed in a way, that inside the tube water or another liquid circulates. The air flows around outside the tubes or the fins/lamellas. The connection between the fins and the tube is used to enlarge the space for heat transfer between the liquid and the gas fluid. The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-water heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

ANTHERMO GMBH

Germany

Air heat exchangers as finned tube heat exchangers Heat transfer between a gaseous media and a liquid Finned tube heat exchangers are often called air/water heat exchangers or gas/water heat exchangers. Heat transfer between a gas (for ex. air) and a liquid (for ex. water) takes place in the air-/water heat exchangers. To improve the thermal output transfer from the gas to the liquid, fins made of well heat transferring materials are put on the tubes. Very often air-/water heat exchangers are used as exhaust heat exchanger to gain the energy out of warm or hot exhaust fumes. Finned tube heat exchangers can also be used as air heater, air cooler or condenser.

Request for a quote

ANTHERMO GMBH

Germany

Temperation of fluids Pillow plates are used everywhere where liquids must be temperated. In dependence of application the liquids can be cooled or heated. Cause of this wide range of applications pillow plates are used in the process industry, in the cooling industry and in a lot of other industries. Pillow plates are also know as heat exchanger plates, evaporator plates, cooling plates /sheets and thermo plates / sheets. Pillow plates as air-/water-heat exchanger Additionally to the temperation of liquids pillow plates are also used as air-/liquid heat exchangers. In case of polluted or wasted air and if there are high demands for cleaning, more and more pillow plates are used as air-/water-heat exchanger. The large exchange surface and the good possibilities for cleaning are important features for this type of heat exchanger.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS high-temperature heat exchangers: - Transfer to water / thermal oil / air - Abrasion protection for abrasive components in the flue gas or product gas (e.g. wood gas) - Implementation of individual solutions (e.g. with regard to available space, thermal performance) - Use of various high-temperature stainless steels according to the application in question - Own measurements on site

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

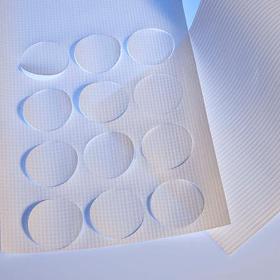

Reduce hydrocarbon emissions with oleophobic marine vents Manufacturers of marine and small engines around the world trust POREX ® oleophobic vents as a key system component to comply with EPA standards for reducing hydrocarbon emissions. With its functional design, these oleophobic vents will not absorb fuel or allow the passage of fuel through the vent, but will allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system. Our oleophobic vents: Provide optimal air-flow exchange – Deliver optimal exchange between the fuel tank and the hydrocarbon absorbing system. Prevent fuel escape from the tank Do not absorb fuel through the vent for tighter control Features Help manufacturers comply with EPA standards for reduced hydrocarbon emissions Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered PTFE membrane and molded...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Reduce hydrocarbon emissions with oleophobic marine vents Manufacturers of marine and small engines around the world trust POREX ® oleophobic vents as a key system component to comply with EPA standards for reducing hydrocarbon emissions. With its functional design, these oleophobic vents will not absorb fuel or allow the passage of fuel through the vent, but will allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system. Our oleophobic vents: Provide optimal air-flow exchange – Deliver optimal exchange between the fuel tank and the hydrocarbon absorbing system. Prevent fuel escape from the tank Do not absorb fuel through the vent for tighter control Features Help manufacturers comply with EPA standards for reduced hydrocarbon emissions Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered PTFE membrane and molded...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Reduce hydrocarbon emissions with oleophobic marine vents Manufacturers of marine and small engines around the world trust POREX ® oleophobic vents as a key system component to comply with EPA standards for reducing hydrocarbon emissions. With its functional design, these oleophobic vents will not absorb fuel or allow the passage of fuel through the vent, but will allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system. Our oleophobic vents: Provide optimal air-flow exchange – Deliver optimal exchange between the fuel tank and the hydrocarbon absorbing system. Prevent fuel escape from the tank Do not absorb fuel through the vent for tighter control Features Help manufacturers comply with EPA standards for reduced hydrocarbon emissions Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered PTFE membrane and molded...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Reduce hydrocarbon emissions with oleophobic marine vents Manufacturers of marine and small engines around the world trust POREX ® oleophobic vents as a key system component to comply with EPA standards for reducing hydrocarbon emissions. With its functional design, these oleophobic vents will not absorb fuel or allow the passage of fuel through the vent, but will allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system. Our oleophobic vents: Provide optimal air-flow exchange – Deliver optimal exchange between the fuel tank and the hydrocarbon absorbing system. Prevent fuel escape from the tank Do not absorb fuel through the vent for tighter control Features Help manufacturers comply with EPA standards for reduced hydrocarbon emissions Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered PTFE membrane and molded...

Request for a quote

BÜRKLE GMBH

Germany

Universal thread adapter for nearly all drums and other containers with opening of 48–75 mm in diameter, regardless of the respective thread. The thread adapter can be mounted quickly and easily with clamping screws and can be used for different container openings. With G2" connector thread for Bürkle drum screw connections and pumps with immersion tube diameter up to 32 mm. The container connectors make decanting even easier and safer with their more secure connection to barrels. The connectors secure the pump in the barrel, enable a vertical position change and allow the required air exchange.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Reduce hydrocarbon emissions with oleophobic marine vents Manufacturers of marine and small engines around the world trust POREX ® oleophobic vents as a key system component to comply with EPA standards for reducing hydrocarbon emissions. With its functional design, these oleophobic vents will not absorb fuel or allow the passage of fuel through the vent, but will allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system. Our oleophobic vents: Provide optimal air-flow exchange – Deliver optimal exchange between the fuel tank and the hydrocarbon absorbing system. Prevent fuel escape from the tank Do not absorb fuel through the vent for tighter control Features Help manufacturers comply with EPA standards for reduced hydrocarbon emissions Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered PTFE membrane and molded...

Request for a quote

TROTEC GMBH

Germany

The TTV 3000 is a real whirlwind on every construction site. This unit is a true professional: distinctive German industrial design with built-in carrying handle, shock-protected switch and stackable polyethylene housing. And all other features of the TTV 3000 are nothing to hide either. With its high-performance, encapsulated fan, this conveying fan which is as robust as lightweight can variably transport fresh air over long distances into adjacent storeys or shafts and exhaust polluted air over equally long distances. Those are ideal conditions for the required air exchange rates for ventilation during channel construction works or welding. Hoses of up to 38 metres in length can flexibly be attached to the blow-out or suction side of the TTV 3000 because this axial fan is equipped with the respective connections on both sides.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

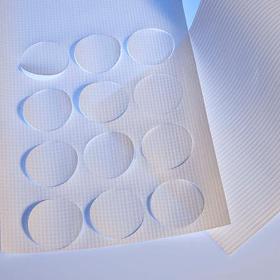

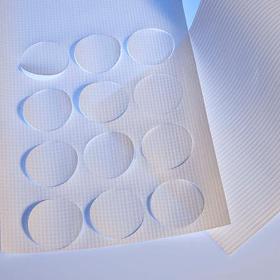

Increase power and performance of small engines Highly designed filters and vents are critical for a small engine’s performance. Our filters and vents work to help small engines deliver more powerful performance. Optimized for small engines, our filters and vents: Increase engine durability– Filters are proven to withstand the harsh fuel environment Enhance performance– Filters have self-orienting ability so that performance is consistent no matter the position of the power tool. Provide optimal air-flow exchange by delivering optimal exchange between the fuel tank and the atmosphere. Features Filters are self-orienting no matter the position of the power tool Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered Filters – Advanced porous materials – PE or PP Vents – PTFE membrane and molded components Formats Available PE or PP – molded shapes PTFE – Rolls or...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VKF RENZEL GMBH

Germany

Air purifiers for the targeted improvement of air quality in large public and commercial areas (including canteens, refectories, retirement homes, cinemas, open-plan offices, fitness studios, etc.) In the basic version, filtration is carried out by a 2-stage filter system consisting of a pre-filter and aerosol filter (HEPA filter). Optionally, the device can be equipped with a switchable UV-C lamp. Due to the extremely high air exchange rate of 5000 m³/h, the PLR Max is ideally suited for halls, halls, event rooms, canteens. Equipped with stable castors, the PLR Max fits through any standard door and is therefore mobile. AREAS OF APPLICATION - Medicine (group practice, laboratory) - Public (retirement home, nursery school/nursing home school, museum) - Commercial (open-plan office, cinemas, dance studios, restaurant) APPLICATION SPECTRUM - Aerosols, viruses and bacteria - Allergens (mould spores, pet hairs, house dust mites, pollen, dust)

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase power and performance of small engines Highly designed filters and vents are critical for a small engine’s performance. Our filters and vents work to help small engines deliver more powerful performance. Optimized for small engines, our filters and vents: Increase engine durability– Filters are proven to withstand the harsh fuel environment Enhance performance– Filters have self-orienting ability so that performance is consistent no matter the position of the power tool. Provide optimal air-flow exchange by delivering optimal exchange between the fuel tank and the atmosphere. Features Filters are self-orienting no matter the position of the power tool Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered Filters – Advanced porous materials – PE or PP Vents – PTFE membrane and molded components Formats Available PE or PP – molded shapes PTFE – Rolls or...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase power and performance of small engines Highly designed filters and vents are critical for a small engine’s performance. Our filters and vents work to help small engines deliver more powerful performance. Optimized for small engines, our filters and vents: Increase engine durability– Filters are proven to withstand the harsh fuel environment Enhance performance– Filters have self-orienting ability so that performance is consistent no matter the position of the power tool. Provide optimal air-flow exchange by delivering optimal exchange between the fuel tank and the atmosphere. Features Filters are self-orienting no matter the position of the power tool Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered Filters – Advanced porous materials – PE or PP Vents – PTFE membrane and molded components Formats Available PE or PP – molded shapes PTFE – Rolls or...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase power and performance of small engines Highly designed filters and vents are critical for a small engine’s performance. Our filters and vents work to help small engines deliver more powerful performance. Optimized for small engines, our filters and vents: Increase engine durability– Filters are proven to withstand the harsh fuel environment Enhance performance– Filters have self-orienting ability so that performance is consistent no matter the position of the power tool. Provide optimal air-flow exchange by delivering optimal exchange between the fuel tank and the atmosphere. Features Filters are self-orienting no matter the position of the power tool Oleophobic and won’t absorb fuel or let fuel past the vent Allow for optimal air-flow exchange between the fuel tank and the hydrocarbon absorbing system Materials Offered Filters – Advanced porous materials – PE or PP Vents – PTFE membrane and molded components Formats Available PE or PP – molded shapes PTFE – Rolls or...

Request for a quote

TROTEC GMBH

Germany

The 44 Kg TTW 25000 S barrel fan with dimension 1,060*525*1,140mm is designed to introduce a cost efficient option for semi-professional use both indoors and out being no less than the similar TTW series that are much more professional and expensive.In places where there is a requirement for high air exchange rates within investment expenditure such as ventilation tasks in production environments, agriculture or storage areas,these barrel fans are quite efficient. The device with a galvanized steel case and a chassis is also equipped with an inclined drum capable of being variably aligned for vertical flow positions,making it easily portable.This enables the direction of air current at high wall or ceiling sections as well. Practical advantages: A cost-saving option for semi-professional ventilation applications Air circulation capacity to 27,600 m³/h Plug-in devices easy to handle

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-vibrating heat exchanger are used in a number of processes in which bulk solids have to be cooled, heated, dried etc. These special-purpose units are able to perform the heat exchange process during transportation. Usually, this occurs indirectly through the use of double bottoms to accommodate the heat exchange medium (oil, water, air, etc.). AViTEQ heat exchangers are employed in practically every industry (chemical, food, plastics, pharmaceutical, recycling and raw materials). The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits gentle product treatment optimised and customised modification to suit existing processes low wear and pra

Request for a quote

TROTEC GMBH

Germany

TTK 355 S COMMERCIAL DEHUMIDIFIERThe new value-for-money leader in the 70 litre class Reduce high levels of relative humidity in minimum time or easily keep large rooms dry – the TTK 355 S is in its element, this is what it was made for. This becomes possible because of a clever combination of a strong 1.27 kW rotary compressor and a quality fan for air flow rates of up to 1,000 m³/h. Thanks to the high air circulation, the tuned heat exchange system is always able to feed extreme humidity from the ambient air for quick drying. Up to 70 litres of humidity can be removed from the room air per day with just one TTK 355 S in this manner. At the same time, compared with other defrost systems, the high-quality hot gas automatic defrost of the TTK 355 S guarantees a much more efficient dehumidification performance without defrost pauses on a time interval during which no dehumidification occurs.

Request for a quote

BETONBAU GMBH UND CO. KG

Germany

Our ventilation systems ensure that an optimum air exchange is achieved within technical buildings (e.g. for cooling transformer and low voltage rooms) and prevent penetration by snow, rain and insects. Individual elements can be flexibly adapted to suit building conditions and are suitable for integration in both doors and walls. Designs: Standard surface: anodised aluminium E6 EV 1 silver Production in recommended sizes or to suit building conditions With a horizontal perforated sheet (for LLE) With integrated swirl chamber for use in conditions involving driving snow and high wind speeds (for LSU/LSO) Aerating coupling for continuous venting Ventilation domes Miniature ventilators Slide ventilators Options: Anodised, painted or powder-coated surface – choice of colours Slide plate for manual air flow control Ventilator units for forced ventilation and aeration All-round swirl frame Special version for Type LLE: break-in inhibiting WK3 conforming to DIN ENV 1627 Our DRO and...

Request for a quote

SERVOLIFT GMBH

Germany

The SERVOLIFT drying station completes the cleaning steps in the SERVOLIFT semi-automatic wash station. The still-damp containers are placed in the drying station, which is placed in a separate drying area. The work is done nearby in the same room. The system can be used as a compact unit separated in an equipment area. The drying station takes up very little space. The complete system ensures a successful drying process in the shortest time with very low energy use. Fast and efficient Technical description Drying using air circulation with approximately 60% fresh air input Heat exchanger, electric, approx. 9KW Drying temperature up to 80° C Control - microcontroller with digital display Adapter for drums Vertical or horizontal construction

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quote

OGE GROUP

Germany

Shell and Tube Heat Exchangers | Air Coolers, Air Heaters, Pressure Vessels | Gas cooling in pneumatic conveying systems | Air cooling in industrial refrigeration | Air drying in textile machines | Air heating & cooling in HVAC systems | Coolers for A.C and D.C motors | Coolers for power transformers | Diesel and gas engines water cooling | Air preheaters for boiler plants | Economizers for steam, oil and hot water generation | Hydrocarbon condenser | Industrial process water cooling | Inter and after coolers | Oil cooling in lubrication system | Solvent recovery by condensation | Steam condenser

Request for a quoteResults for

Air exchangers - Import exportNumber of results

42 ProductsCountries

Company type