- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 5 axis milling

Results for

5 axis milling - Import export

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

The 5-axis machining centres from the HF series are optimally equipped to meet the exacting requirements of modern production processes. Enabling 5-sided and simultaneous 5-axis machining, they allow you to handle many different tasks on a single machine. Highly productive and flexible, with easy operation and maintenance, available with pallet changer or table loading. The second generation of the HF series provides numerous optimisations, including new spindle units with increased performance and the advantages of the HELLER zero-spindle system for minimised life cycle costs. Moreover, the option of a second drive in the Z-axis allows for even more universal application, including single-part production. In combination with the proven HELLER DNA of productivity, precision and reliability, they guarantee you increased performance, precision and flexibility for the production of your workpieces.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Designed for Production: The new generation of 5-axis machining centres F sets a new benchmark for cutting performance and precision With its head kinematics, the new generation of the 5-axis F series has been designed from the ground up for flexible series production. Like all HELLER machines, they set a benchmark for cutting performance and precision. Other highlights include free chip fall, short idle times, optimum automation capability and compatibility with the H and FP series for a wide range of workpieces. In addition, the new models come with top-of-the-range specifications and the option to add technologies such as Mill-Turn, interpolation turning or power skiving.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs.Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Within the HERMLE range of models, the C 250 is an entry-level model into the world of 5-axis & 5-sided machining. Nevertheless, the “large” models are in no way inferior. Thanks to the large swivelling range of the workpieces in the working area, the utilisation of the complete traverse range and the large collision circle between the table side walls, the C 250 offers the largest working area relative to the installation area. The C 250 is designed for daily use – maximum user-friendliness thanks to pivotable control panel and minimum table distance from the operator and optimum loading height with option ofloading by crane. Maximum precision thanks to the HERMLE swivelling rotary table concept. The table variants of the C 250 therefore stand for the highest quality and optimum use of material – from the cast housing to the installed gear motors: Made in Germany – made in Gosheim.

Request for a quote

SNK GMBH

Germany

◆High-rigidity continuous 5-axis spindle head ・This machine is equipped with a highly rigid continuous 5-axis spindle head which enables the continuous machining of high-strength materials such as iron, titanium, and difficult-to-cut materials without using axis clamping mechanism ・High-rigidity square 450 mm ram and unique high torque rotating structure gives max. rotating torque of 6600 N・m for B and C axis

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

CNC 5 axis milling of aluminium, brass, steel, plastics etc. at our DMG ecoMill 70 (workspace XYZ 750 x 600 x 520 mm), DMG DMU 75 Mono-Block (workspace XYZ 750 x 650 x 560mm) and Elumatec SBZ-151 (workspace XYZ 9000 x 1150 x 715 mm)

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

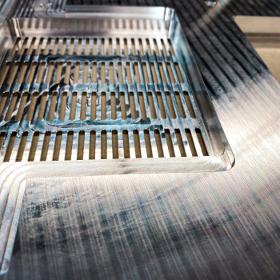

These are accessories for precision machining.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodizing is an electrochemeical process that creates a durable, corrosion-resistant layer on the surface of metals, particularly aluminum. This layer, known as an oxide layer, can be colored to enhance the aesthetic appeal of the product. The colors that can be achieved through anodizing are varied.The most commonly used anodizing colors include red, blue, green, black, yellow, purple, and orange.The function of anodizing is to enhanced durability, scratch-resistance, and corrosion-resistance.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

PA6 (polyamide 6 or nylon 6) is a common engineering plastic that has many advantages: 1, high mechanical strength: PA6 has a high tensile and compressive strength, good toughness. 2. Good wear resistance: Its surface is smooth, the friction coefficient is small, and the wear resistance is excellent. 3. Self-lubricity: When the friction effect is not too high, PA6 can be used without lubricant. 4. Corrosion resistance: PA6 has a good tolerance to alkali and most salts, and can resist the erosion of gasoline, oil, fat, alcohol, etc. 5, excellent electrical performance: PA6 has good electrical insulation, even in high humidity environment can maintain good electrical insulation performance. 6, easy to process: PA6 molding processability is excellent, can be injection molding, blow molding, casting, spraying and so on.These characteristics make PA6 widely used in automotive, electronic and electrical, mechanical equipment and other fields.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The parts are used for the stent of the machine,they can hold and connect two parts together,provide the function of the bracket.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for milling and turning operations HELLER process competence at its best: machine series providing unique cutting performance for milling and turning operations Highlights Combined Processing: milling and turning on a single machine Tool provides 5th axis: 5-axis machining, horizontal, vertical and tilted turning High precision and cutting forces for turning operations due to specific spindle fixation Rotary table with direct torque drive Integrated balancing function Advantages A one-off investment that ensures flexible production today and in the future One machining centre for all machining tasks Two machine variants (CP/pallet changer or CT/table loading) providing maximum flexibility for use Typical HELLER performance for milling and turning operations Reliable productivity thanks to HELLER services

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Most modern equipped, we meet your demands on highest level! For the mechanical processing, we use modern manufacturing technologies which ensure tailor-made optimized solution on a constantly high quality level. Whether individual parts or small and medium-scale productions, whether small components or XXL parts, we remain at your service. For the customer's data transfer, our modern 2D & 3D CAD systems are available. ■ CNC turning: up to 3000 mm / Ø420 mm (118"/Ø16") ■ CNC milling: up to 7000/2500/1500 mm (275"/98"/59"), part weight up to 10 T (2204 lbs) ■ 5-axis treatment up to Ø 1000 mm (39"), part weight up to 1,2 T (2645 lbs)

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

SCHMIDT Zerspanungstechnik uses state-of-the-art metal working machines to apply the finishing touches SCHMIDT Zerspanungstechnik's modern milling machines make it possible to custom-machine work pieces to extremely high precision during contract manufacturing work. Our machinery includes several universal machining centres and computer-controlled CNC milling machines; among them column, bed and gantry milling machines. 5-axis milling technology allows the machine to position and move the milling cutter at any angle to the workpiece which makes producing extremely complex 3D contours possible. In addition to this, our machines offers qualitative benefits in that almost all points to be machined can be reached without having to re-clamp the work piece. We also have fully controlled rotary index tables and indexing heads, and work with magnetic and vacuum clamping systems. We're able to machine work pieces of up to 10,000 mm in size.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik uses state-of-the-art metal working machines to apply the finishing touches SCHMIDT Zerspanungstechnik's modern milling machines make it possible to custom-machine work pieces to extremely high precision during contract manufacturing work. Our machinery includes several universal machining centres and computer-controlled CNC milling machines; among them column, bed and gantry milling machines. 5-axis milling technology allows the machine to position and move the milling cutter at any angle to the workpiece which makes producing extremely complex 3D contours possible. In addition to this, our machines offers qualitative benefits in that almost all points to be machined can be reached without having to re-clamp the work piece. We also have fully controlled rotary index tables and indexing heads, and work with magnetic and vacuum clamping systems. We're able to machine work pieces of up to 10,000 mm in size.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

Our workshop is equipped with CNC boring mills SCHMIDT Zerspanungstechnik's modern machinery offers a variety of options when it comes to the contract manufacturing and machining of work pieces and large machine parts. As a reliable machinist of large parts, SCHMIDT Zerspanungstechnik relies on state-of-the-art CNC boring mills whose complex movements are controlled by computer and which can be programmed. The employees working in our machine shop have modern 5-axis boring mills with axis travels of 3,500 x 2,000 x 1,500 mm at their disposal. They allow us to perform heavy-duty machining jobs as well as all other typical milling work. Our complete mastery of this flexible manufacturing process guarantees high-quality results are achieved in the most efficient way.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

Our workshop is equipped with CNC boring mills SCHMIDT Zerspanungstechnik's modern machinery offers a variety of options when it comes to the contract manufacturing and machining of work pieces and large machine parts. As a reliable machinist of large parts, SCHMIDT Zerspanungstechnik relies on state-of-the-art CNC boring mills whose complex movements are controlled by computer and which can be programmed. The employees working in our machine shop have modern 5-axis boring mills with axis travels of 3,500 x 2,000 x 1,500 mm at their disposal. They allow us to perform heavy-duty machining jobs as well as all other typical milling work. Our complete mastery of this flexible manufacturing process guarantees high-quality results are achieved in the most efficient way.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

High performance simultaneous 5 axis mill turn center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis mill turn center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis mill turn center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Cutting from small to large Whether turning or milling, small or large parts - Siempelkamp Maschinenfabrik is available to you as a competent manufacturer for your components. Thanks to our many years of experience in machining technology, we oer you the highest quality, precision and technical knowhow for consulting and manufacturing your product. Key features workpiece weight up to 450 t 5-axis turning and milling Advantages certied production quality almost incomparable production possibilities wealth of experience

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

CNC 5 axis milling of aluminium, brass, steel, plastics etc. at our Datron ML1500-4 (workspace XYZ 1500 x 2000 x 240 mm), Datron ML1600 (workspace XYZ 1600 x 2500 x 240 mm), Datron MLCube (workspace XYZ 1500 x 1000 x 245 mm) and Datron M8Cube (workspace XYZ 1000 x 800 x 245 mm)

Request for a quote

F. ZIMMERMANN GMBH

Germany

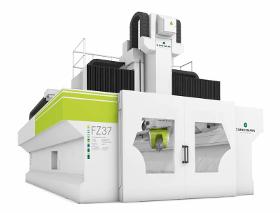

Universal metal cutting machine. Designed for highly dynamic machining of different materials. High-speed machining ensures efficient milling results. Advantages: - outstanding price-performance ratio - very broad application spectrum - high-quality universal head for simultaneous machining

Request for a quote

F. ZIMMERMANN GMBH

Germany

Extremely high structural rigidity together with very fast-acting drives. Reinforced portal, cast side stands, high structural stability. Top surface quality and excellent dynamic response. Ideal for machining steel, cast iron and heavy materials like titanium. Spindle-change concept for economical complete machining. Advantages: - top surface quality - better dynamic performance - high efficiency

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ 30 and FZ 35 Portal Milling Machines are the economical solution for a vast variety of tasks. For finishing, and with the FZ 35 even roughing of steel and cast alloys, light alloys and plastics, these machines can be used for all types of materials*. This model range satisfies the sector-specific requirements of many industries. - In pattern and mold making for machining patterns, molds, injection-molding dies and sheet-metal forming tools in all their variety. - Outstanding capacity utilization, because different parts can be set-up at the same time and then machined in succession – of course in unmanned shifts as well. - In aircraft production for the trimming of panels, stretchforming parts, rudders etc., or for special applications of acrylic sheet, cockpit canopies for example. - In ship and boatbuilding for the manufacture of laminating forms, deck structures etc.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ 35 Portal Milling Machine is the economical solution for a vast variety of tasks. For finishing and roughing of steel and cast alloys, light alloys and plastics, these machines can be used for all types of materials*. This model range satisfies the sector-specific requirements of many industries. - In pattern and mold making for machining patterns, molds, injection-molding dies and sheet-metal forming tools in all their variety. - Outstanding capacity utilization, because different parts can be set-up at the same time and then machined in succession – of course in unmanned shifts as well. - In aircraft production for the trimming of panels, stretchforming parts, rudders etc., or for special applications of acrylic sheet, cockpit canopies for example. - In ship and boatbuilding for the manufacture of laminating forms, deck structures etc.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The 5-axis portal milling machine FZ 25 is a universal solution for the machining of highly complex and at the same time voluminous components. Model materials as well as composites through to light alloys can all be machined with this HSC gantry machine. This machine range fulfils the specific requirements of many sectors: - In the automobile design where large models need to be produced (e. g. cars on a scale of 1:1). - In pattern and tool making, especially in connection with very large workpieces with deep contours need to be machined (e. g. large rotation-symmetric moulds such as tanks and pools, etc.). - In the boatbuilding and shipbuilding industries, where huge work areas are required in all three axes, since the components are often elongated in shape. - In the aircraft industry, e. g. for milling panels, other large parts and components with extreme contours. In the wind energy industry with its long thin blades and bulbous hubs.

Request for a quoteResults for

5 axis milling - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Milling - machine tools (7)

- Milling - steels and metals (6)

- Machine tools, metal machining - parts and accessories (3)

- Mechanical engineering - custom work (2)

- Sawmills - machinery and equipment (2)

- Steels and metals - machining (1)

- Machine tools - metal machining (1)

- Automobiles (1)

- Couplings, mechanical (1)

- Inductive sensors (1)

- Laser - cutting and welding machines (1)

- Weaving - machinery and equipment (1)