- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 3d controls

Results for

3d controls - Import export

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

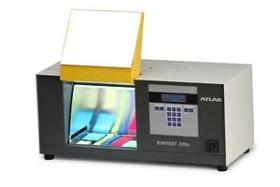

The Atlas SUNTEST CPS+ is the small entry model. CPS+ is the most widely used benchtop xenon instrument in the world. Its compact design, easy handling and proven reliability make it the ideal quality control and R&D screening device for a variety of industries, such as plastics, packaging, pharmaceuticals, cosmetics, and many more. 1x 1500 W air-cooled Xenon Lamps 560 cm 2 exposure area Measurement and control of Irradiance in the wavelength range 300-800 nm / Lux; or 300-400 nm / 340 nm Measurement and control of Black Standard Temperature (BST) Display of Chamber Temperature Display of Test Values and Diagnostic Messages Parameter Check Two pre-programmed test methods Storage for 6 user-defined test methods Multilingual User Interface Benchtop design 90 x 35 x 35 cm Static, horizontal exposure area for flat or 3D specimen Fan-controlled BST from 45-100 °C (without chiller unit SunCool) Non-aging reflector and filter system, consistent of selectively reflecting mirrors and a coated quartz Switch-off choices Radiant Exposure or Test Time Base Filter as carrier for additional optical filters Data output via serial interface RS232 Internally integrated Memory Card for Software Updates Light Monitor 300-400nm Light Monitor 300-800nm Humidity Sensor for measuring relative humidity during testing

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XLS+ is an with state-of-the-art UV-control for reliable R&D screening tests. The benchtop design fits into every lab while optional accessories – water spray, immersion, refrigeration – expand the testing capabilities and offer easy ways to customize it to your needs. It comes standard with a 1100 cm 2 exposure area, suiting multiple flat or 3D samples. 1x 1700 W air-cooled Xenon Lamps 1100 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and Control of Irradiance in the wavelength range 300-800 nm / Lux; or 300-400 nm / 340 nm Measurement and Control of Black Standard Temperature (BST); BPT optional Measurement of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Bench-top design 90 x 54 x 62 cm Static, horizontal exposure area for flat or 3D specimen Temperature control of BST in the range 45-100 °C; BPT 45-95 °C Fan-controlled temperature difference between Chamber Temperature and BST Light cassette including non-ageing aluminium reflector, uncoated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Irradiance control wide band 300 – 800 nm (Lux) or narrow band 300 – 400 nm BST/BPT exchange kit

MICRO-EPSILON

Germany

The Industrial Performance Unit is a powerful computing platform for the efficient commissioning of Micro-Epsilon 3D sensors. The fully compatible controller is ideally suited to inline processes in 3D measurement tasks. The intuitive 3DInspect software with Valid3D technology enables simple and fast sensor parameter setting, which allows measurements to start immediately. The Industrial Performance Unit directly processes three-dimensional data, which is subsequently evaluated and assessed via the 3DInspect software. Results can be output via the integrated PROFINET, EtherCAT and EtherNet/IP interfaces.

Request for a quote

MEGATRON ELEKTRONIK GMBH & CO. KG

Germany

The optimized industrial module in modern design for intuitive control of 6 degrees-of-freedom (6 DOF), by pushing, pulling, rotating, tilting of the ergonomically handle The SpaceMouse® Module is the ideal man-machine interface for controlling 3D movements in industrial applications - only with one hand! It is the ideal input device for teaching robots, moving cameras, measurement systems, drones etc. The module covers both rotation and translation movements due to the 6-axis sensor. Consequently, it may replace two conventional joysticks in many applications, and thus the SpaceMouse® Module increases the control capabilities of the operator, saves space in control panels, and reduces investment costs. Totally new control concepts and control panels can be realized, without need of extensive training of the operator.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 161i neo is the latest high-precision plasma cutting system for the cutting range between 0.5 mm and 50 mm. Equipped with the soft-switch inverter technology, it offers a wide range of possibilities for cutting and marking thin and medium-sized sheets. It meets the requirements of the metal and container construction industries, the engineering and automotive industries and many other sectors. The HiFocus 161i neo can be combined with 2D as well as 3D CNC-controlled guiding systems, i.e. gas cutting systems, robots and pipe cutting systems.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 280i neo is one of the most flexible and most powerful high-precision plasma cutting units. It covers a cutting range from 0.5 mm to 70 mm. The latest inverter technology allows the highest marking quality and functionality on the market. The HiFocus 280i neo is ideally suited for steel service centers, steel producers and distributors.It can be combined with 2D or 3D cnc-controlled guiding systems like gas cutting machines, robots and pipe cutting machines. With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient. The HiFocus 280i neo is available as standard with the Contour Cut Technology for cutting fine inner and outer contours and small holes in mild steel.

Request for a quoteResults for

3d controls - Import exportNumber of results

7 ProductsCountries

Company type