- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- 3-axis milling

Results for

3-axis milling - Import export

LECHMANN ENGINEERING GMBH

Germany

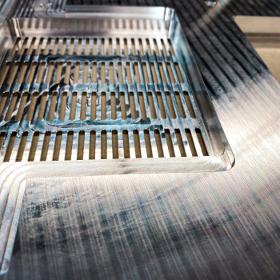

CNC 5 axis milling of aluminium, brass, steel, plastics etc. at our Datron ML1500-4 (workspace XYZ 1500 x 2000 x 240 mm), Datron ML1600 (workspace XYZ 1600 x 2500 x 240 mm), Datron MLCube (workspace XYZ 1500 x 1000 x 245 mm) and Datron M8Cube (workspace XYZ 1000 x 800 x 245 mm)

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are accessories for precision machining.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are used for industrial camera accessories。

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used for the machine,made by aluminum, then doing black anodizing.Exquisite appearance and precision tolerance control.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodizing is an electrochemeical process that creates a durable, corrosion-resistant layer on the surface of metals, particularly aluminum. This layer, known as an oxide layer, can be colored to enhance the aesthetic appeal of the product. The colors that can be achieved through anodizing are varied.The most commonly used anodizing colors include red, blue, green, black, yellow, purple, and orange.The function of anodizing is to enhanced durability, scratch-resistance, and corrosion-resistance.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

PA6 (polyamide 6 or nylon 6) is a common engineering plastic that has many advantages: 1, high mechanical strength: PA6 has a high tensile and compressive strength, good toughness. 2. Good wear resistance: Its surface is smooth, the friction coefficient is small, and the wear resistance is excellent. 3. Self-lubricity: When the friction effect is not too high, PA6 can be used without lubricant. 4. Corrosion resistance: PA6 has a good tolerance to alkali and most salts, and can resist the erosion of gasoline, oil, fat, alcohol, etc. 5, excellent electrical performance: PA6 has good electrical insulation, even in high humidity environment can maintain good electrical insulation performance. 6, easy to process: PA6 molding processability is excellent, can be injection molding, blow molding, casting, spraying and so on.These characteristics make PA6 widely used in automotive, electronic and electrical, mechanical equipment and other fields.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used in industrial filter.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

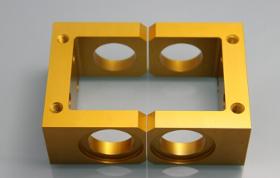

This parts is made by aluminum, after 3-4 axis machining, then, going golden anodize,it is used in the external support of the machine.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is for products with very high surface requirements.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turn-milling compound machining flange

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts are milled by aluminum,which used in architectural decoration industry.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used for printer accessories.After CNC Milling ,deburring, then doing black anodizing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the optical fiber fastener which accessories used in electronic. They were made by brass, optical fiber fasteners are essential components in the field of fiber optics. Optical fiber fasteners play a crucial role in managing and securing fiber optic cables. They are designed with specific features to ensure the safety and integrity of the cables, making them an indispensable tool in the field of fiber optics.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

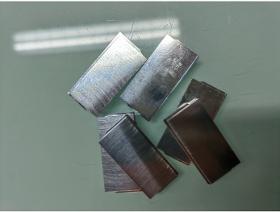

These parts used for the precision machinery parts,made by brass and no surface treatment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the base parts used in construction.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Most modern equipped, we meet your demands on highest level! For the mechanical processing, we use modern manufacturing technologies which ensure tailor-made optimized solution on a constantly high quality level. Whether individual parts or small and medium-scale productions, whether small components or XXL parts, we remain at your service. For the customer's data transfer, our modern 2D & 3D CAD systems are available. ■ CNC turning: up to 3000 mm / Ø420 mm (118"/Ø16") ■ CNC milling: up to 7000/2500/1500 mm (275"/98"/59"), part weight up to 10 T (2204 lbs) ■ 5-axis treatment up to Ø 1000 mm (39"), part weight up to 1,2 T (2645 lbs)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used, partially overhauled three-spindle, horizontal machining center Product name: MFZ 2-3 Update Machine number 53152 Used 3-spindle horizontal 4-axis machining center Year of construction: 2009 The machine produced until October 2020 Sinumerik 840D Powerline control X-axis travel: 300 mm Y-axis travel: 500 mm Z axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z-axis 60000mm/min 3 motor milling spindles GMN, version with HSK63 tool holder Drive power (S1 / S6) 28 KW (constant) Torque (S1 / S6) 63/83 Nm Maximum speed 16,000 rpm Chip conveyor Knoll (scraper belt conveyor in the setting across the machine) Knoll coolant system with paper belt filter Flushing gun • Complete housing Tool storage (3 x 30 tools) Operating voltage 400V 3N ~ Control voltage 24V DC

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

F. ZIMMERMANN GMBH

Germany

The core technology is a robust, water-cooled travelling column. With increasing depth of immersion into the material, the guide carriage distance grows and this leads to advanced rigidity. The stepped drive guide ensures a perfectly constant geometry along the Z axis. This in turn guarantees maximum rigidity in sensitive areas of the workpiece. Used in combination with the highly dynamic Zimmermann milling heads, the FZH400 ensures an extremely efficient milling process during the machining of aluminum and composites. The versatility of the M3ABC 3-axis milling head improves efficiency due to the maximized material removal rate, in particular when machining structural parts. An integral standard component of the FZH400 is its pallet handling capability with an area for setting up pallets during machine operation. The newly developed handling system permits the reliable transportation of the pallets, is suitable for longer pallet lengths, and can be extended without difficulty.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

Designed for Production: The new generation of 5-axis machining centres F sets a new benchmark for cutting performance and precision With its head kinematics, the new generation of the 5-axis F series has been designed from the ground up for flexible series production. Like all HELLER machines, they set a benchmark for cutting performance and precision. Other highlights include free chip fall, short idle times, optimum automation capability and compatibility with the H and FP series for a wide range of workpieces. In addition, the new models come with top-of-the-range specifications and the option to add technologies such as Mill-Turn, interpolation turning or power skiving.

Request for a quote

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

The 5-axis machining centres from the HF series are optimally equipped to meet the exacting requirements of modern production processes. Enabling 5-sided and simultaneous 5-axis machining, they allow you to handle many different tasks on a single machine. Highly productive and flexible, with easy operation and maintenance, available with pallet changer or table loading. The second generation of the HF series provides numerous optimisations, including new spindle units with increased performance and the advantages of the HELLER zero-spindle system for minimised life cycle costs. Moreover, the option of a second drive in the Z-axis allows for even more universal application, including single-part production. In combination with the proven HELLER DNA of productivity, precision and reliability, they guarantee you increased performance, precision and flexibility for the production of your workpieces.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

SCHMIDT Zerspanungstechnik uses state-of-the-art metal working machines to apply the finishing touches SCHMIDT Zerspanungstechnik's modern milling machines make it possible to custom-machine work pieces to extremely high precision during contract manufacturing work. Our machinery includes several universal machining centres and computer-controlled CNC milling machines; among them column, bed and gantry milling machines. 5-axis milling technology allows the machine to position and move the milling cutter at any angle to the workpiece which makes producing extremely complex 3D contours possible. In addition to this, our machines offers qualitative benefits in that almost all points to be machined can be reached without having to re-clamp the work piece. We also have fully controlled rotary index tables and indexing heads, and work with magnetic and vacuum clamping systems. We're able to machine work pieces of up to 10,000 mm in size.

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

CNC 5 axis milling of aluminium, brass, steel, plastics etc. at our DMG ecoMill 70 (workspace XYZ 750 x 600 x 520 mm), DMG DMU 75 Mono-Block (workspace XYZ 750 x 650 x 560mm) and Elumatec SBZ-151 (workspace XYZ 9000 x 1150 x 715 mm)

Request for a quoteResults for

3-axis milling - Import exportNumber of results

23 ProductsCountries

Company type

Category

- Milling - steels and metals (2)

- Milling - machine tools (2)

- Machine tools - metal machining (2)

- Couplings, mechanical (2)

- Steels and metals - machining (1)

- Automobiles (1)

- Bicycle accessories (1)

- Bridges - construction (1)

- Furniture and decorations, garden (1)

- Inductive sensors (1)

- Laboratory equipment and instruments (1)

- Laser printing (1)

- Lenses, camera (1)

- Mechanical engineering - custom work (1)

- Optical measuring equipment (1)

- Sawmills - machinery and equipment (1)

- Sensors (1)

- Textiles - Machines & Equipment (1)

- Water purification (1)