- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- manual presses

Results for

Manual presses - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The Load cell model 8451 has been developed for measuring the forces that occur during press operation. The internal measuring elements have a rugged design, which mean they can cope reliably with the steep force curves that are typical of press applications. They can be fitted or replaced quickly and easily on the press ram without the need for additional components around them. The force sensor is placed between the tool and the press ram and can thus measure the actual compression force directly in the axis of operation. The load cell measures the compression forces between the circular contact surfaces of plunger and tool. The pin on its top side and hole on its lower face are simply provided for mechanical fixing and centering the components correctly. The connecting cables are suitable for drag chains, designed for many movements and stably fastened in the sensor housing.

Request for a quote

BORNEMANN GMBH

Germany

Manual stamping presses for steel, tool and machine engineering for simply labelling of multi-digit texts. For standard stamping presses we offer font sizes of 1 to 10 mm with 11 labelling fields on the wheel circumference. By removing the pin stop, the wheels can be easily rotated, which allows setting the desired combination. The striking cap can also be replaced.

Request for a quote

BORNEMANN GMBH

Germany

Our low-cost alternative to manual stamping presses are standardised mini markers with a font size of 2, 3 or 4 mm, 6 wheels with relevant wheel labelling from 0 to 9 as well as an empty field. With the pin stop, the figure combination can be changed in a simple procedure and embossed on a tool to be labelled with manual marking.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Pressure on price and quality continue to rise. The need to monitor even the simplest manufacturing and assembly process is increasingly common. With 100% monitoring of force/ time curves or force displacement/time curves, the Force- Master satisfies all requirements for ensuring the reliability of even simple press-fit processes. Thanks to its ultra-simple, single-button operation and intelligent auto-configuration, even semi-skilled staff can set up the equipment safely and quickly. "Card & Go" is the smart system that uses master, tool and PLC smart cards to make equipment settings, inhibit unauthorized changes and to trigger actions in sequence with the production process. The ForceMaster 9110 has been developed specifically for monitoring manual lever presses. Simple manual workstations can be monitored extremely efficiently using the ForceMaster. Easy control functions that used to require an additional PLC can now be performed reliably with the ForceMaster.

Request for a quote

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

The filter presses from AQUACHEM of the EC Beverage series are used in the beverage industry, for example, for the filtration of selected wines. Another feature is that the filter elements are gasketed, and therefore the must or juice does not also come into contact with the ambient air. The EC Beverage series is offered as standard in the filter plate sizes 470, 630 and 800 mm.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

In the tried-and-tested, gasketed design, the EC-series offers many benefits to the user on top of its ease of operation. Due to the internal drainage, use in even the most hygienically clean areas is possible. The press lock is performed by an automatically self-regulating pneumatic/hydraulic closing system. The automatic closing pressure maintenance ensures that the plate pack always remains closed. An adjustable pressure switch with a potential-free contact is provided for integration into the customer's control system. This prevents the feeding pump from running uncontrollably. Also, as with all AQUACHEM filter presses, the discharge manifold can be generated here at the customer's request. Due to the gasketed design, the seamless backflushing of the filter media in the filter press is possible. The filter press frame is phosphated and powder-coated, offering a high level of protection against external influences.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Pressing bearings Manually assemble anti-knock on hand lever press Automatically assemble and test retaining ring

Request for a quote

DEKORTECH GMBH

Germany

Manual clam shell type heat press for textile transfers. ✔ Singe platen ✔ Even temperature and pressure ✔ Opens automatically ✔ Up to 50 x 60cm base plate ✔ Magnetic closure ✔ Pull out base plate This quality heat press is great for small businesses. With a long lever it is easy to close this clam shell type heat press. Once closed, a magnet holds the press shut and automatically opens once the set dwell time is reached. The pull-out base makes it even easy to place the textile and transfer. Furthermore, a small gap underneath the base plate allows you to thread the t-shirt onto the platen. Using a small display, you can adjust temperature and a rotary know allows to set the pressure. Last, a special coating on the heated element avoids stains. With a range of different base platens, this press can be used for t-shirts, hoodies, bags, sleeves, legs, bags, neck tags and a lot more.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

The "hand spraying robot" with EJ86 spray head was developed to provide a uniform and reproducible spray pattern in the forging process. It is based on a KUKA robot of the 20 kg class with a specially developed, simplified user interface! With this operating concept, available exclusively from Jerko, time-consuming and expensive robot training at the manufacturer is a thing of the past. Equipped with all necessary interfaces, the robot can be "safely" integrated into new or existing forging lines. Each robot has "Safe Operation" to spray safely even on manually operated presses.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

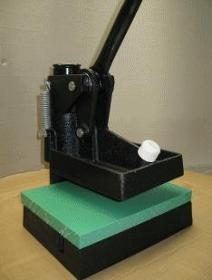

We started using this machine for soft materials in 2013 where a lot of customers asked us for another smaller option beside a swing beam press! With the STAR MA3 we can offer you a solution! It works exactly like a bigger swing beam press. The cutting head is attached to a cylinder on the backside of the machine. The force isn't made by hydraulic systems. It is made manually through a 812mm long handle on the front of the machine. The head is inclined a few degress like a bigger swing beam press. This is balanced if the cutting head is under force. This many is used worldwide for small quanitities for cutting leather, pictures or laboratory works. But it can also be soft materials like in the following list: •Abrasives •carpets •elektronic parts •foamed plastic •Shoes •rubber •Leather articles •packaging •Paper •Textiles

Request for a quoteResults for

Manual presses - Import exportNumber of results

11 ProductsCountries

Company type