- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- punching

Results for

Punching - Import export

BRUNO UNGER GMBH & CO KG

Germany

Punching knives in different shapes and sizes

Request for a quote

PRESSTA EISELE GMBH

Germany

Punch tools to work aluminium profiles Customized Production Single or Chain tools Holes, notches, bending Tool size up to 1.200 mm Power up to 800 KN

Request for a quote

PRESSTA EISELE GMBH

Germany

0 – 300 mm adjustable pneumatic material feed and digital display Vertical hydraulic punching unit to the right of the saw blade Power 200 KN Punching tools according to profile shape Aluminium profile – finished Cut to length Vertical punching Up to 8 profiles in one operation cycle Cycle time from 13 s / 1,63 s each piece Layout of punching tools for multiple profiles Quick change punching tools according to the profile shape Pneumatic material feed 8 profiles at once Special shaped quick change support Clamps according to profile shape – changeable Hydraulic punching unit Power 200 KN, stroke 20 mm Cycle spray mist device for each die and for the saw blade

Request for a quote

PRESSTA EISELE GMBH

Germany

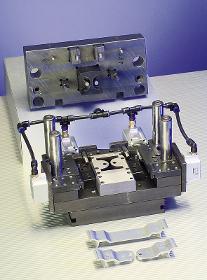

Quick change tool system Hydraulic operated Foot valve operated Max. power at 260 bar = 400 KN Stroke = max. 80mm adjustable via limiter switch 20 Double strokes / min. Max. daylight = 300 mm Working range: ram to back wall = 200 mm Table dimension: 600 x 400 mm Quick change tool system

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydraulic operated Foot valve operated Max. power at 260 bar = 200 KN Stroke = max. 80mm adjustable via limiter switch 20 Double strokes / min. Max. daylight = 300 mm Working range: ram to back wall = 200 mm Table dimension: 600 x 400 mm Quick change tool system

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydraulic operated Foot valve operated Max. power at 200 bar = 160 KN Stroke = max. 80 mm adjustable via limiter switch 14 Double strokes / min. Max. daylight = 250 mm Working range: ram to back wall = 130 mm Working range with turn table: ram to back wall = 90 mm Table dimension: 280 x 200 mm

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 90 KN Stroke = 40 mm 25 Double strokes / min. Max. daylight = 250 mm Working range: ram to back wall = 130 mm Working range with turn table: ram to back wall = 90 mm Working height 950 mm

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 50 KN Stroke = 37 mm Max. daylight = 200 mm Working range: ram to back wall = 110 mm Swiveling table to use tools to manufacture holes for sash bars

Request for a quote

PRESSTA EISELE GMBH

Germany

Base with hardened guides Hydraulic device; Motor 4,0 kW, 400 V, 50 Hz Operation panel to switch on/off single or multy head mode Foot pedal controlled C-formed stand, working range – ram to back wall 120 mm Daylight 280 mm, quick tool change Distance punch head to punch head min. 245 mm Punching power 60 / 120 kN, stroke 50 mm – stroke adjustable optionally Carriage with linear guides for manual adjustment in X-direction, with pneumatic clamps and positioning scale

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

For punching film or plastic packaging, manufactured according to customer requirements

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The Professional Line punching machines by EHRT are characterised by their outstanding robustness even under high loads. With the Professional machines a three-shift operation, for example, is not an issue. This machine is fitted with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding in the material and removing the production parts can be further automated. This makes the machines extremely cost-effective. Software solutions from EHRT enable a customised and smooth production flow of punching machines. In addition, the punching machine can be optimally linked with the bending machine so that production can be carried out based on a single production file from a common database.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The new FlexPunch series features a very flexible and modular system. Each machine can be adapted to the customer’s individual requirements via individual components. The FlexPunch series is equipped with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. Through additional options, however, the processes of feeding the material and removing the production parts can be further automated. This makes the punching machines extremly cost-effective. EHRT's software solutions enable a customised and smooth production flow of punching machines. In addition, the punching machines can be optimally linked with the bending machines so that production can be carried out based on a single production file from a common database.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The Professional Line punching machines by EHRT are characterised by their outstanding robustness even under high loads. Running a three-shift operation, for example, is not an issue. The Punching Machine Professional Series is fitted with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding in the material and removing the production parts can be further automated. This makes the machines extremely cost-effective.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The new FlexPunch series features a very flexible and modular system. Each machine can be adapted to the customer’s individual requirements via individual components. The FlexPunch compact is the smaller version of the two and is particularly suited for production sites with limited space. The FlexPunch series is equipped with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding the material and removing the production parts can be further automated. This makes the punching machines extremely costeffective.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

AMZ stands for automated material loading. AMZ enables automated loading of metal bars into our punching machines. Different materials types (thickness/width) can be processed successively. This only requires a short manual intervention when changing the type of metal bars, which allows for an ideal preparation of the production process. As soon as the machine has been started, the operator no longer needs to deal with feeding in the material, and can sort and further process the production parts during this time. The AMZ can also be seen as a small intermediate storage facility.

Request for a quote

RHEINPAPERCUP GMBH

Germany

max speed:300 stroke 14 kw. 380 V. eye mark sensor. servo motor. mold change possible in one hour

RHEINPAPERCUP GMBH

Germany

3 or 4 color flexo printing machine. anilox roller 300 LPI ink pump EPC and CORONA eye mark sensor, servo motor. 100 m per min. printing speed. new machine .

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Punching - Import exportNumber of results

17 ProductsCountries

Company type