- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- modular design

Results for

Modular design - Import export

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The rotor debarker is ideal for use wherever reliably and thoroughly debarked logs are required. The abrasive debarking tools make the rotor debarker the first choice for logs that are especially hard to debark and for frozen wood. The narrow design ensures the parallel position of the logs in the machine. The modular design allows high flexibility for a needs-based log feed. Features, Function Modular design Needs-based configuration according to throughput amount, type of wood, and degree of debarking Debarking by means of abrasive and wear-resistant debarking tools Advantages Adjustable degree of debarking Suitable for frozen logs (permafrost) Suitable for logs with different diameters Quiet operation Options 2 or 3 rotors per section

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The rotor debarker is ideal for use wherever reliably and thoroughly debarked logs are required. The abrasive debarking tools make the rotor debarker the first choice for logs that are especially hard to debark and for frozen wood. The narrow design ensures the parallel position of the logs in the machine. The modular design allows high flexibility for a needs-based log feed. Features, Function Modular design Needs-based configuration according to throughput amount, type of wood, and degree of debarking Debarking by means of abrasive and wear-resistant debarking tools Advantages Adjustable degree of debarking Suitable for frozen logs (permafrost) Suitable for logs with different diameters Quiet operation Options 2 or 3 rotors per section

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

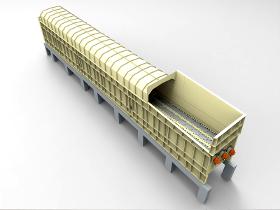

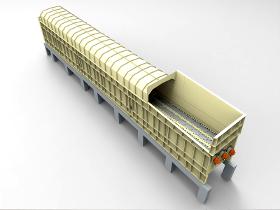

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of fiberboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Features, Function Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Manufacturing of large-scale machine components on site Options Horizontal conveyer for long logs Gravity feed chute for short logs

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The drum debarker, type PDD, was developed for the economical and gentle debarking of logs. The drum debarker is not only used for the production of fiberboards or OSB but in all industries where thoroughly debarked round logs are required. The system, based on a modular design, was built for the debarking of logs with medium and large diameters at high capacity in order to meet the high demands of panel manufacturers. Features, Function Electromotive drive Power transmission via truck tires Wear-resistant carriers for log transports Adjustable retention time of the logs Debarking by friction of the logs against each other Advantages Adjustable degree of debarking Economical and at the same time gentle debarking Modular design allows an adjustment to the required plant capacity Manufacturing of large-scale machine components on site Options Horizontal conveyer for long logs Gravity feed chute for short logs

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The new FlexPunch series features a very flexible and modular system. Each machine can be adapted to the customer’s individual requirements via individual components. The FlexPunch series is equipped with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. Through additional options, however, the processes of feeding the material and removing the production parts can be further automated. This makes the punching machines extremly cost-effective. EHRT's software solutions enable a customised and smooth production flow of punching machines. In addition, the punching machines can be optimally linked with the bending machines so that production can be carried out based on a single production file from a common database.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The new FlexPunch series features a very flexible and modular system. Each machine can be adapted to the customer’s individual requirements via individual components. The FlexPunch compact is the smaller version of the two and is particularly suited for production sites with limited space. The FlexPunch series is equipped with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding the material and removing the production parts can be further automated. This makes the punching machines extremely costeffective.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Modular design - Import exportNumber of results

6 ProductsCountries

Company type

Category