- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial tools

Results for

Industrial tools - Import export

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik provides jig making services for many branches of industry As a competent partner in the field of tool making, we perform repair, maintenance and modification work on our customers' tools. We also carry out development work on the tools according to the customer's requirements and drawings. These extremely high-quality tools are used in a variety of production processes and serve as quality assurance for our industrial customers during the manufacture of their products. The expertise and knowledge we bring to bear when carrying out customisation, repair and maintenance work on special-purpose and custom-made tools assists our customers in finding the optimal solution. Our tools are purchased by manufacturing operations and end users in various branches of industry. SCHMIDT Zerspanungstechnik boasts state-of-the-art CNC manufacturing technology

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Non-woven cleaning tool for the quick change system with ceramic high-performance abrasive grain. • Stable edges • Maximum cleaning performance • Quick tool change without bonding or sliding

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Ceramic grain fibre disc for the quick change system – the grain enables rapid and superior stock removal performance. • Especially suitable for hardened and tempered steels, tinder areas and titanium • Perceivably faster stock removal • Quick tool change without bonding or sliding

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Continuous-feed belt with ceramic grain for stationary belt grinders. • Bond from synthetic resin with abrasive grain fillers for cooler grinding • Closed coating for high stock removal performance on steel and stainless steel • Tear-resistant X-polyester fabric, waterproof for a long lifetime

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Flexible continuous-feed belt with ceramic grain for hand-guided belt grinders. • Bond made from synthetic resin enriched with abrasive grains for a cooler cut • Closed coating for high stock removal performance on steel and stainless steel • Flexible, tear-resistant cotton T-fabric for a long lifetime

Do you sell or make similar products?

Sign up to europages and have your products listed

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Quick and aggressive grinding with very high stock removal performance, thanks to a large contact surface and extra-long flaps. • Ceramic grain offers high stock removal performance • Especially suitable for hardened and tempered steel, tinder areas and titanium • Particularly good for edge grinding

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Fillet weld flap disc – the combination of a 10 mm flap projection and rigid fabric makes for a long lifetime. • High stock removal performance through ceramic grain • Optimised for fillet weld work • Optimal price-performance ratio

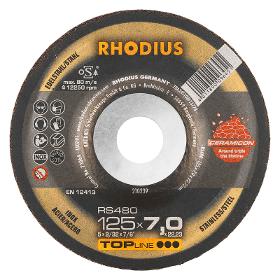

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. High-performance stainless steel rough grinding disc with ceramic abrasive grain. Also performs very well on steel and cast iron. • High stock removal performance • Additional fabric flange from 180 mm for high-frequency and air grinders • Safe thanks to three full-face fabric layers

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Non-woven cleaning abrasive with ceramic high-performance abrasive grain. For powerful cleaning performance and an extremely long lifetime. • Stable edges • Top cleaning performance • With ceramic high-performance abrasive grains

EHRT MASCHINENBAU GMBH

Germany

The new FlexPunch series features a very flexible and modular system. Each machine can be adapted to the customer’s individual requirements via individual components. The FlexPunch series is equipped with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. Through additional options, however, the processes of feeding the material and removing the production parts can be further automated. This makes the punching machines extremly cost-effective. EHRT's software solutions enable a customised and smooth production flow of punching machines. In addition, the punching machines can be optimally linked with the bending machines so that production can be carried out based on a single production file from a common database.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The Professional Line punching machines by EHRT are characterised by their outstanding robustness even under high loads. Running a three-shift operation, for example, is not an issue. The Punching Machine Professional Series is fitted with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding in the material and removing the production parts can be further automated. This makes the machines extremely cost-effective.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The new FlexPunch series features a very flexible and modular system. Each machine can be adapted to the customer’s individual requirements via individual components. The FlexPunch compact is the smaller version of the two and is particularly suited for production sites with limited space. The FlexPunch series is equipped with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding the material and removing the production parts can be further automated. This makes the punching machines extremely costeffective.

Request for a quote

EHRT MASCHINENBAU GMBH

Germany

The Professional Line punching machines by EHRT are characterised by their outstanding robustness even under high loads. With the Professional machines a three-shift operation, for example, is not an issue. This machine is fitted with three CNC controlled axes, allowing for production parts to made with virtually perfect accuracy. No additional employees are needed to adjust the machine, which saves a significant amount of time. The operator is only responsible for starting the machine, feeding in the material and then removing the production parts. Feeding in the material and removing the production parts can be further automated. This makes the machines extremely cost-effective. Software solutions from EHRT enable a customised and smooth production flow of punching machines. In addition, the punching machine can be optimally linked with the bending machine so that production can be carried out based on a single production file from a common database.

Request for a quoteResults for

Industrial tools - Import exportNumber of results

14 ProductsCountries

Company type