- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feeders

Results for

Feeders - Import export

SAMSYS GMBH

Germany

The short bar loading magazine Multi 3000 was developed in Switzerland. Manufactured in Germany with first-class materials and components. The MULTI-3000 guarantees long-term reliability. It impresses with its service and environmentally friendly design. It is also a fully electric and servo-controlled magazine. Easy access to all parts makes it extremely user-friendly. It is very simple to understand and therefore easy to operate. Set-up and changeover is possible within 2-5 minutes due to the well thought-out design. The patented lifting mechanism guarantees an impact-free and fast loading cycle. Further features are the smooth material feed, an optimal control and monitoring of the material feed, as well as the exact positioning of the bar without mechanical stop. Due to its design, the Multi 3000 does not require a shifting device to change the Spindle Liner. A shifting device is optionally available in X- and Z-axis and in different lengths.

Request for a quote

SAMSYS GMBH

Germany

The small bar feeder Samsys Smart impresses with its high performance in a very small space. The bar feeder is manufactured in Germany with first-class materials and components. The Samsys Smart guarantees long-term reliability. It impresses with its service and environmentally friendly design. It is an electro-pneumatic magazine. This means the feed is servo-controlled and the reloading mechanism is pneumatic. Due to the easy access to all parts it is extremely user-friendly. This makes it very simple to understand and easy to use. Set-up and changeover is possible within 2-5 minutes due to the well thought-out design. Further features are the smooth material feed, an optimal control and monitoring of the material feed, as well as the exact positioning of the bar without mechanical stop. Due to its design, the Samsys Smart requires very little floor space. A shifting unit to gain easy access to the reduction tube is standard in X-direction.

Request for a quote

SAMSYS GMBH

Germany

Unloading machine Multi-3000 remove The Multi-3000 remove is an electro-pneumatically controlled automatic unloading machine. It is the ideal complement to the bar feeder Multi 3000 or the Multi 3000SL. With the Multi 3000 remove it is possible to unload finished parts from sub- or main spindle. The bars are unloaded by unloading tube, pneumatic gripper or also by collet chuck. After unloading, the bars are placed on a prism. From the prism the parts are transported to a deposit. A light barrier monitors the unloading process. The coating of the depositing surfaces enables a particularly gentle handling of the finished parts. Even parts such as piston bars can be unloaded without a scratch. The unloading tube is made of POM material. This also ensures gentle handling. Loading can be done via the main spindle and unloading via the sub spindle. It is also possible to load via the sub spindle and unload via the main spindle. Compatible with almost all types of lathes.

Request for a quote

SAMSYS GMBH

Germany

The spindle extension SamSpindle, has been specially designed for the extension of lathe spindles. Together with the bar feeder Multi 3000 it forms a safe, clean and efficient solution. The SamSpindle operates oil and air free. There is no mechanical connection to the lathe. Only a minimum of moving parts and masses. These are: the rotating bar, the guide rings and the inner cage of the ball bearings. The guide rings mounted in the roller bearings keep the bars in the centre of the SamSpindle cartridge. Thanks to this technique, round or test bars can be rotated at high speed, ensuring remarkably smooth running. You can turn drawn, round or profile bars, with correct straightness, at the maximum spindle speed of the lathe. This allows us to guarantee workpieces with high precision. The SamSpindle spindle extension offers maximum safety. It does not allow access to parts in motion. The moving parts are all enclosed in the SamSpindle cartridge, which is closed by a safety nut.

Request for a quote

SAMSYS GMBH

Germany

The AutoSAM 3.26 is an automatic bar feeder with hydrodynamic bar guidance. It is particularly suitable for connection to sliding headstock lathes (Swiss-Type). Its field of application is in small, medium and large series. Its big brother is the bar loading magazine AutoSAM 3.51. The bar feeder has a calibration-free material clamping which is carried out by collets. This saves time for material change due to the automatic centric positioning. Four clamping jaws ensure maximum hold while the collet is being pulled onto the bar. The Mitsubishi PLC control system with PC board ensures extreme process reliability and simplifies communication with the lathe. Compatible with almost all types of lathes. For example Citizen, Star, Nomura, Mazak, Okuma, DMG Mori, SMEC, Doosan, Nakamura, CMZ, Takamaz and many more.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAMSYS GMBH

Germany

The basis of short bar loader Multi 3000SL was developed in Switzerland. It was specially designed for turning machine types with a large distance between machine cover and spindle end. The bar feeder is supplied as standard with a Z-axis sliding unit to ensure free access to the Spindle Liner. This makes it easy to change the spindle insert tube. The Bar Loading Magazine is manufactured in Germany with first-class materials and components. The MULTI-3000SL guarantees long-term reliability. It impresses with its service and environmentally friendly design. It is also a fully electric and servo-controlled magazine. Due to the easy access to all parts it is extremely user-friendly. It is very simple to understand and therefore easy to operate. Due to the well thought-out design, set-up and changeover is possible within 2-5 minutes. The patented lifting mechanism guarantees an impact-free and fast loading cycle.

Request for a quote

SAMSYS GMBH

Germany

With the new intelligent OnRobot screwdriver for light industrial, cooperation and assembly robot you can easily automate processes. Intelligent error detection and handling of multiple screw sizes ensures consistent results and drastically reduces your cycle time. Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. Functionality Due to the simple connection of the screwdriver and the operation and programming via the own URCap (only applies to Universal Robots) the grippers are ready for use in the shortest time. In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Request for a quote

SAMSYS GMBH

Germany

ar feeder for special profiles wanted ? To extend the MULTI 3000 to the bar feeder for special profiles, the Uni-erector can be mounted optionally. It enables the erection of rectangular profiles and special profiles for further transport to connected machine tools. Thus a smooth reloading process is possible. By simply setting a parameter, the erector can be selected or deselected. This enables a quick changeover from round material to a special profile. By deactivating it, the bar loader can load round or hexagonal material as normal. While with activated parameter the bar feeder will load the special or rectangular profile while the reloader is erecting. The use of square material is also optionally possible. The erector consists of two opposite rollers. To erect the material, these rollers move together during reloading. When the bar is threaded into the machine tool, the rollers open again. The distance between the rollers can be easily adjusted.

Request for a quote

CL MACHINERY GMBH

Germany

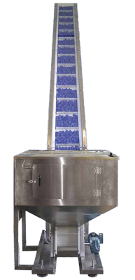

Closure Systems International's closure elevator pre-feeders are designed to feed closures to sorters from the ground level. Via a cleated belt, closures are fed from a bulk storage bin at ground level to a sorter mounted on a capping machine. CSI Closure Pre-Feeder Features & Benefits Stainless steel construction Bin sizes available: ✓ 10 cubic feet ✓ 25 cubic feet ✓ 50 cubic feet ✓ 100 cubic feet Can be custom designed to meet any delivery rate Can be custom designed for any closure size and type Clean-out door for quick changeover Lexan bin cover for clear visibility Lexan conveyor cover to keep dust out High and low level photo sensors Self-contained stainless steel control panel Controls can be integrated with capper controls Best to be combined with a rotary sorter and placed next to the capper Markets Served: Beverages, Food, Pharmaceutical, Automotive Fluids, Personal Care, Home Care, and Custom Applications Unmatched Technical Support / Application Expertise!

CL MACHINERY GMBH

Germany

Closure Systems International's JetFlow is a bulk closure feed system that automatically conveys plastic, aluminum, or crown closures to remote sorters. The system delivers closures in a controlled, continuous manner and eliminates manual filling of closure sorters. This easy-to-use, flexible system boosts productivity, helping bottlers maximize their total cost of operations. JetFlow High Performance Features & Benefits Configured to suit bottler's individual operation Best combination for rotary sorters With cap conveying chutes, unit can be located up to 200 feet away from the production floor / capper, keeping closures clean and dry Can simultaneously feed multiple cappers Made of easy-to-clean stainless steel Clear Lexan top doors, allowing operators to see when refilling is needed Cyclone Decelerator, designed to gently handle plastic closures 18 inch height x 21 inch diameter 6 inch discharge chute Markets Served: Beverages, Food, Pharmaceutical, Automotive Fluids,...

EWM AG

Germany

Compact inverter welding machine with integrated wire feed mechanism. Available with 3 different control variants: LP, HP, Expert 2.0. Can be retrofitted with optional modular water block Cool 50 U40 or tool box for storing welding accessories, e.g. welding torch. — Excellent Multimatrix welding characteristics — Equipped at no extra charge with Synergic characteristics for GMAW welding of steel/CrNi/aluminium — Equipped at no extra charge with EWM Synergic characteristics for forceArc, forceArc puls, rootArc, rootArc puls and superPuls — Suitable for MMA welding, TIG welding and gouging at no extra charge — 16 individually configurable programs for each welding task (JOB) — Large power reserves thanks to high duty cycle with all components heating up less as a result, guaranteeing a longer service life for machines when in use — Adjustable start and end crater functions — Synergic or manual welding mode

Request for a quoteResults for

Feeders - Import exportNumber of results

12 ProductsCountries

Company type