- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- handles

Results for

Handles - Import export

SAMSYS GMBH

Germany

The silicone gripper Soft Gripper from OnRobot can pick up a wide variety of irregular shapes and delicate objects. This makes it ideal for pick-and-place applications. The Soft Gripper is particularly suitable for applications in food and beverage production, manufacturing and packaging. The gripper is available with three interchangeable silicone-coated suction cups. Whether eggs, fruit, bottles or cans – this silicone gripper from OnRobot makes food and beverage automation easier. Like all OnRobot grippers, the Soft Gripper can be seamlessly integrated into the robot of your choice. The Soft Gripper operates without an external air supply, so there is no additional cost or complexity, and no dust or noise is generated as with conventional grippers. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Request for a quote

SAMSYS GMBH

Germany

Since the vacuum gripper VG10 does not require a compressor or an air supply, it is a compact and easy to move solution. This makes your production line more flexible and saves maintenance costs. It has flexible arms and an adjustable vacuum. This allows the VG10 to handle different objects in many different sizes. Furthermore, your efficiency is further increased because it is a double gripper. This means you can control the right and left side of the vacuum gripper independently of each other. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. The vacuum gripper is equipped with double gripper functionality, a tool changer and various common suction cup attachments. In addition, there are many third party suction cup attachments on the market to suit any application.

Request for a quote

SAMSYS GMBH

Germany

The compact, electric vacuum gripper VGC10 offers infinite adjustment possibilities. It also has optional suction cups for almost any application. The VGC10 is smaller than the VG10, making it suitable for tight environments where it can expand your automation capabilities. With the same payload, but half the weight of the VG10, the VGC10 can lift small, bulky and heavy objects even with a smaller robot arm. The VGC10 has two independently controlled air ducts. This allows it to be used as a double gripper with pickup and release in one action. This further increases efficiency and reduces throughput time. Since neither compressor nor air supply is required, this compact electric grab is easy to move. Easy programming allows it to be quickly reassigned, providing greater production flexibility. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Request for a quote

CL MACHINERY GMBH

Germany

Closure Systems International's Elevator Sorters take closure sorting to a new level, incorporating innovative design features, advanced technology, and reduced cost of operations. CSI's SE24 Elevator Sorter provides excellent reliability and quick, easy, low maintenance. SE24 High Performance Features & Benefits Sorting speed: up to 1,000 caps per minute CSI's quick-change Slope-Lok® allows operator to adjust closure sorting while running to eliminate upside down caps Full access for removal Fold-down guard for built-in workspace Energy efficient: no compressed air required to discharge closures Flexibility for multiple closure sizes: Flat caps ranging in diameter from 26mm to 43mm Sports caps ranging in diameter from 26mm to 28mm Quick-change cleats allow operator to adjust for closure size eliminating need for costly extra belts Full changeover in 15 minutes Innovative louver system reduces closure "knock-off" and improves sorting efficiencies Closure bin / hopper designed...

CL MACHINERY GMBH

Germany

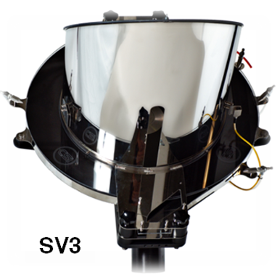

Closure Systems International's SV Series Rotary Sorters are simple to operate and keep your capping operation running smoothly. CSI's robust, efficient rotary sorter designs allow only correctly oriented closures to be fed through the cap chute for unsurpassed capping reliability. CSI Rotary Sorter High Performance Features Maximum versatility: can be either post-mounted in mezzanine or mounted on top of CSI capping machines SV2, SV3 and SV21 designed to orient flat closures, plastic and aluminum, ranging in diameter from 20mm to 38mm SV131 and SV197 designed to orient both flat closures, plastic and aluminum, ranging in diameter from 20mm to 55mm SV813 - 815, SV32, SV41, and SV50 designed to orient both flat and sport closures as well as wider diameter closures, up to 110mm Simple changeovers: accomplished by flipping a switch Sorting speed approximations (based on 28mm caps): ✓ SV2: 350 caps per minute ✓ SV3: 750 caps per minute ✓ SV21: 950 caps per minute ✓ SV41: 600 caps per...

Do you sell or make similar products?

Sign up to europages and have your products listed

CL MACHINERY GMBH

Germany

Closure Systems International is committed to servicing your bottling system needs. CSI's goal is to improve output and decrease the overall cost of bottler's operations. Reducing broken tamper bands during manufacturing is one way to reduce costs. The number one cause of broken pilfer bands is cold temperature. Therefore, CSI offers a heating system for acclimatizing closures for cold season capping; the system warms closures prior to application to reduce the risk of broken bands without damaging the closure, helping to maximize application performance and improve overall packaging costs. High Performance Heater Features & Benefits Reduces risk of broken tamper bands without closure damage Just the right volume of low temperature air introduced to closure by means of a specially designed injector Controlled by a thermostat, the unit enables desired temperatures to be reached for varying material and packaging characteristics, even after closures have been exposed to cold...

CL MACHINERY GMBH

Germany

Closure Systems International's JetFlow is a bulk closure feed system that automatically conveys plastic, aluminum, or crown closures to remote sorters. The system delivers closures in a controlled, continuous manner and eliminates manual filling of closure sorters. This easy-to-use, flexible system boosts productivity, helping bottlers maximize their total cost of operations. JetFlow High Performance Features & Benefits Configured to suit bottler's individual operation Best combination for rotary sorters With cap conveying chutes, unit can be located up to 200 feet away from the production floor / capper, keeping closures clean and dry Can simultaneously feed multiple cappers Made of easy-to-clean stainless steel Clear Lexan top doors, allowing operators to see when refilling is needed Cyclone Decelerator, designed to gently handle plastic closures 18 inch height x 21 inch diameter 6 inch discharge chute Markets Served: Beverages, Food, Pharmaceutical, Automotive Fluids,...

CL MACHINERY GMBH

Germany

Closure Systems International’s new FT24 Flat-Top Sorters incorporate innovative features and advanced technology to deliver improved throughput with a reduced height sorter design. CSI’s FT24 Flat-Top Sorters provide the ultimate in reliable, high speed performance while optimizing total cost of operations. FT24 High Performance Features & Benefits High-speed sorting: over 3000+ caps per minute New flat-top discharge design to improve throughput and reduce sorter height Floor level sorting and closure conveying Same proven, reliable closure feed and belt design as CSI’s popular, high-speed ES24 Elevator Sorter Belt speed modulates to maintain buffer in discharge single filer High-speed single file air conveyor maintains back –pressure and closure throughput with no stops or gaps Constant back-pressure means no minimum chute length regardless of feed-rate required Tested at feed-rates in excess of 3000 caps per minute Discharge section tested at speeds in excess of 4000 caps per..

CL MACHINERY GMBH

Germany

Closure Systems International's Elevator Sorters take closure sorting to a new level, incorporating innovative design features, advanced technology and reduced cost of operations. CSI's ES24 Elevator Sorter provides the ultimate in reliable, high speed performance and low maintenance. ES24 High Performance Features & Benefits Highest sorting speed: over 2,500 caps per minute Unsurpassed energy efficiency: no air required to discharge caps Non-contact closure elevating eliminates adjustments Belt assisted metering optimizes closure acceleration Flexibility for multiple closure sizes: Flat caps ranging in diameter from 26mm to 43mm Sports caps ranging in diameter from 26mm to 28mm Remote easy access bin provides quick, reliable changeovers Footprint: 2,195mm x 2,124mm Standard Height: 3,800mm; custom elevation requirements can be accommodated Integrated bin design available to reduce sorter footprint Quick access to upper & lower discharge Right or left hand discharges...

EHRT MASCHINENBAU GMBH

Germany

AMZ stands for automated material loading. AMZ enables automated loading of metal bars into our punching machines. Different materials types (thickness/width) can be processed successively. This only requires a short manual intervention when changing the type of metal bars, which allows for an ideal preparation of the production process. As soon as the machine has been started, the operator no longer needs to deal with feeding in the material, and can sort and further process the production parts during this time. The AMZ can also be seen as a small intermediate storage facility.

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Optimal use of space due to its compact design • Reduction of the footprint by more than 40% in comparison to fork gripper systems • Gentle handling of complete product layers • Handling of a variety of pallet configurations with only one gripper • Format parts are not required, thus reducing complexity and freeing warehouse space TheWave is a unique combination of a conveyor element with a layer gripper resulting in a machine that can take complete product layers arriving from the conveyor lane and – independent of product type and configuration – place them safely onto a pallet. TheWave can be used in all sectors of the consumer industry branch and for almost all products. Its compact design makes it possible – in contrast to the usual systems using fork or clamp grippers – to save enormously on floor space.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Easy programming + maintenance via the PLC: no robot programming skills required • Optimal utilization of space + considerable space saving due to compact design • Highly flexible palletizing solution allows for any number of layer patterns • Layer weights of up to 200 kg possible • Gentle product handling of complete layers • Consistent and proven Langhammer operating concept allows for easy configuration In contrast to conventional systems with fork/clamp grippers, this compact design results in an enormous space saving of up to 40%. The new Articulated Arm Robot AR500 in combination with either Siemens or Rockwell controls guarantees easiest programming and maintenance directly via the PLC. By combining the Articulated Arm Robot AR500 with TheWave Langhammer offers a coordinated concept for the complete material flow, characterized by extreme accuracy & high-quality palletizing – and everything according to customer requirements – ready to go from a single source

Results for

Handles - Import exportNumber of results

13 ProductsCountries

Company type