- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- maintenance doors

Results for

Maintenance doors - Import export

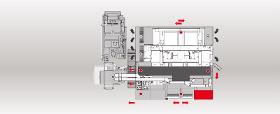

SAMAG MACHINE TOOLS GMBH

Germany

BEST POSSIBLE ERGONOMICS & EFFICIENCY OF MAINTENANCE: FOR OPERATORS No platform required for machine loading and operating area Pivotable main control panel with good visibility into the work area FOR MAINTENANCE & SERVICE Sliding doors on the back provide generous central maintenance access to the machine, doors in the setup room can be opened wide Central and easily accessible media supply, hydraulic unit and maintenance access for A and W axis through movable housing segment

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

installation of bagtype filters, panel filters, compact filters, filter pads, HEPA filters and activated carbon cartridges 30 mm air duct flanges connecting duct to upstream and downstream side tightly closing, lateral maintenance door with hinges and sash lock fasteners spacesaving simple toolfree filter change maintenance door optionally in right or left air direction

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series F1 - F4 The HEINKEL inverting filter centrifuge of the Series F requires minimum installation space and is characterized by an integrated clean room design. It is suited for use with diffcult to filter products and characterized by hermetically closed design and the fully automated, continuous operation. Special properties for the customer’s benefit: Advanced development of the proven inverting filter centrifuge Series HF Larger basket volume as well as higher centrifugal forces in comparison with Series HF Easy installation, especially in clean rooms because of outer smooth surfaces and machine contours Inerting system and all junction boxes accommodated in the machine housing Easy access to machine housing via maintenance doors at three sides

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer overhead conveyor is used for discharging or transferring products. Distribution occurs in cycle operation and across the direction of transport. Depending on the use case, it is attached to existing machines to save space, or is set up in a free-standing housing. Even large distances can be overcome with the machine. Technical data: —Distribution: 2 lanes —Distribution process in cycle operation —Lane distance: up to 3000 mm —Complete machine cover made of Makrolon with maintenance doors Optional equipment: —Independent electrical control system with congestion monitoring —Loading and unloading belts

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer revolving storage is the space-saving solution for storing solid, cube-shaped general cargo. The storage process occurs in cycle operation. The products move into the machine batch-by-batch and are stored vertically in compartments. The machine works according to the First In-Last Out principle. Technical data: —Length of batch: up to 3000 mm —Number of batches: up to 50 —Independent electrical control system Optional equipment: —Complete machine cover made of Makrolon with maintenance doors —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer synchronized distributor divides the stream of products batch-by-batch and gently into two lanes. During the distribution process the products are not braked, so that functional reliability is ensured even at high speeds. The compact design permits simple incorporation into existing lines. Technical data Distribution: 2 lanes Distribution process during continuous flow of materials Product gap: from 5 mm Conveyor speed: more than 60 m/min. Lane distance: 110 mm, 130 mm Complete machine cover made of Makrolon with maintenance doors Independent electrical control system with congestion monitoring Installation length: 1200 mm Optional equipment Loading and unloading belts

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer accumulation table can store large quantities of glasses, bottles or tins. The products are pushed to the accumulation table if there is backlog. The products are later re-fed into production by operating the system in reverse. The machine works according to the First In-Last Out principle. In case of malfunction, the electrical control system activates the accumulation table based on sensor messages. After the malfunction ends, the stored products are automatically fed into the line. Technical data: —Chain width: up to 3,000 mm —Usable chain length: up to 20 m —Independent electrical control system Optional equipment: —Complete machine cover made of Makrolon with maintenance doors —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer synchronized switch divides the stream of products batch-by-batch and gently into several lanes. During the distribution process the products are not braked, so that functional reliability is ensured even at high speeds. Because the number and width of the lanes to be approached can be freely selected, the machine is suitable as product feed for palletizing machines or similar devices. Technical data: —Distribution: Number of lanes depends on the recipe —Distribution process during continuous flow of materials —Product gap: from 15 mm —Conveyor speed: more than 60 m/min. —Lane distance: depends on recipe —Complete machine cover made of Makrolon with maintenance doors —Independent electrical control system with congestion monitoring Optional equipment: —Loading and unloading belts —Infinitely variable width adjustment

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer switch divides the stream of products into two or more lanes during continuous operation or in cycle operation. You can select either a pneumatic or an electrical drive. The pneumatic drive is characterized by a good price-performance ratio. The electrical drive allows you to divide the stream of products into more than two lanes. Technical data: —Distribution: 2 lanes —Distribution process in cycle operation —Lane distance: up to 250 mm —Pneumatic drive Optional equipment: —Independent electrical control system with congestion monitoring —Loading and unloading belts —Infinitely variable width adjustment —Combination with gripper technology for distribution during continuous operation —Electrical drive for distribution to multiple lanes —Complete machine cover made of Makrolon with maintenance doors

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer head space moistener permits moisting of the cap with the fluid in the container. Machine dimensions depend on the conveyor performance and the desired moisting time. Moisting occurs during continuous material flow. The machine is a space-saving solution due to the vertical moisting track. The design permits products to run through the machine without turning process, if necessary. Technical data: —Conveying performance: up to 60,000 units/h —Moisting path: up to 10 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain optional equipment: —deflecting pulleys —motorized width adjustment —machine cover made of Makrolon or steel grid with maintenance doors —electrical control system —loading and unloading belts

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer rinser is used for interior cleaning of new glass, PET bottles, tins, etc. Water or other liquids are used as cleaning media. Cleaning occurs during continuous material flow. In addition to rinsing, differences in height can be overcome at the same time or products can be turned. Technical data: —Conveyor performance: up to 60,000 units/h —Rinse track: up to 10 m —Difference in height: up to 10 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in a painted or stainless steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain —Water lance for cleaning the products —Complete machine cover made of sheet metal/Makrolon with maintenance doors

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

The BRÜCKNER hotflue is the heart of a continuous dyeing range and depending on the customers’ requirements it can be supplied with oil or gas heating. Due to the intelligent drive concept and a sophisticated air flow control an exact shade homogeneity is achieved across the length and the width of the fabric. Tailing and migrations are prevented and the dyeing results are 100% reproducible. This line is appropriate for all woven fabrics, particularly shirting and trouser fabric as well as home textiles such as bed linen. Benefits are among others best dye uniformity over the complete length and width of the fabric, no tailing, no migration, creasefree production, 100% reproducible dyeing results, minimum consumption of thermal and electrical energy, tailormade solutions for a maximum productivity even with small quantities, easy access for cleaning and maintenance due to large doors.

Request for a quoteResults for

Maintenance doors - Import exportNumber of results

13 ProductsCountries

Company type